What Circuit Breaker Size For a 2000W inverter?

A circuit breaker protects appliances running on a 2000W inverter in case of a surge. For this to work, the breaker must be the right size.

Get a quote

How to Safely Know Load Capacity of A Circuit Breaker

If the load stays at or below 20 amps (and ideally below 16 amps for continuous usage – more on that later), the circuit operates normally. If the load exceeds the breaker''s

Get a quote

National Electric Code (NEC) 120% Rule_Final

In this example, there is a total of 250 amps of power draw that would exceed the safety rating of the busbar, allow it to heat up becoming a serious fire hazard.

Get a quote

How to Size a Circuit Breaker? Breaker Size Calculator

In this post, we will show how to choose the right size circuit breaker for electrical wiring installation and design, considering factors such as the related voltage

Get a quote

Circuit Breaker Size Calculator

Introduction to the Circuit Breaker Size Calculator Our Circuit Breaker Size Calculator is a user-friendly online tool designed to help you quickly calculate the ideal breaker size for your

Get a quote

Recommended Inverter Cable, Breaker & Fuse Sizing

Use this table to decide what size and to use with your inverter. Remember the fuse and breaker are there to protect your cabling from overheating (and potentially catching fire).

Get a quote

How many amps does a 3000 watt inverter draw?

To find the proper wire and fuse (or circuit breaker) sizes for your 3000 Watt inverter, you''ll need to calculate the maximum amp draw of the inverter.

Get a quote

How to Wire an Inverter to a Breaker Panel | home

The inverter turns the DC power from your solar, wind or hydropower source into AC power that your appliances can use. Connecting

Get a quote

What size fuse between battery and inverter?

The amount of current (Amps) that you''d like the inverter to be able to pull from the battery. The amount of current that the wire between your

Get a quote

The 120% Solar Rule Explained & When to Derate Your Breaker

What is the 120% solar rule, and what should you do to meet this criteria? Learn how to calculate and derate your breaker to accommodate your system.

Get a quote

Recommended Inverter Cable, Breaker & Fuse Sizing

Use this table to decide what size and to use with your inverter. Remember the fuse and breaker are there to protect your cabling from overheating (and

Get a quote

Specifications for Electrical Installations

If applicable, National Grid will provide operating device numbers for customer service equipment. This equipment may be, but not limited to, switches, circuit breakers, primary fuses or

Get a quote

Can the total amps of all the breakers in an electrical panel be

An electrician can do a calculation, based on the square footage of the house and a list of the installed appliances, to determine the correct size for your main service panel, and

Get a quote

Amp Chart For Household Appliances

To have an estimation of how many amps your household appliances use when offline, you can check our downloadable amp chart pdf. That way, you can easily figure out

Get a quote

Brief Guide to Selecting Breakers and Isolators for

For the solar inverter at ground level, there will be two feeds connected to the unit, these being the AC electricity grid (for the inverter''s output) and the DC

Get a quote

How to Determine Your Electrical Service Amps

An electrician can do a calculation, based on the square footage of the house and a list of the installed appliances, to determine the correct size

Get a quote

Dedicated circuit for Residential Sewage Pumps

Looks like most regular sized residential sewage pumps are 12-13amps at 120v. I''ve run into 2 recently that were on a 15 Amp circuit, is this

Get a quote

Inverter Amp Draw Calculator: Let''s Simplify It

Short on Time? Here''s The Article Summary The article discusses the importance of monitoring the amp draw of an inverter in a solar power system to manage

Get a quote

How to Calculate Total Amps in a Breaker Panel? – Only 4 Steps

To find the amp capacity of your breakers inside the panel box itself, you can use the Power formula (I=P÷V). Our goal here is to get the amps in your breaker panel before

Get a quote

How To Calculate Total Amps In A Breaker Panel

When it comes to designing a circuit breaker panel, you must understand how the appliances "pull" current. If an appliance attached to a 120V energy source requires 1200

Get a quote

EG4® 12000XP OFF

6. BRIEF INTRODUCTION The EG4® 12000XP is a 12kW 120/240VAC split-phase, all-in-one, off-grid, sine wave inverter with grid charge capability designed for the

Get a quote

Panel and Main Circuit Breaker Sizing for Solar (PV) System

If you are referring to the breaker coming from the inverter, I believe it would need to be based on the maximum current rating of the inverter as shown on the inverter nameplate,

Get a quote

How To Calculate Total Amps In A Breaker Panel

When it comes to designing a circuit breaker panel, you must understand how the appliances "pull" current. If an appliance attached to a

Get a quote

How Many Amps Does an Air Conditioner Use: Types, BTU

Understanding how many amps an air conditioner uses is crucial for homeowners and property managers when planning electrical systems or troubleshooting power issues. Air

Get a quote

How to Safely Know Load Capacity of A Circuit Breaker

If the load stays at or below 20 amps (and ideally below 16 amps for continuous usage – more on that later), the circuit operates normally. If the

Get a quote

How Many Breakers Can I Put in a 200 Amp Panel?

And although a 200 amp panel has many places for circuit breakers, that does not mean you can use all of it. The number of your circuit

Get a quote

6 FAQs about [How many amps does the grid-connected main circuit breaker of the communication base station inverter use ]

How much power does a circuit breaker provide?

Circuit breaker panel: Since the early 1960s, homes have generally been wired with circuit breaker panels that provide 240-volt current. Early services may provide 60 amps of power, while large houses built today may have 200 amps or more of power.

How do electricians determine a breaker size?

An electrician can do a calculation, based on the square footage of the house and a list of the installed appliances, to determine the correct size for your main service panel, and it's typical for the total amps of all the breakers to be more than double the rating of the panel and main breaker.

How many amps does a circuit breaker have?

The amperage of these individual breakers will be between 15 and 50 amps, usually. At the top or bottom end of the two rows of branch circuit breakers, there will be a central circuit breaker that controls the power to the entire panel. This is the main circuit breaker, and its amperage rating will be something like 60, 100, 150, or 200 amps.

What is the amperage rating of a circuit breaker?

This is the main circuit breaker, and its amperage rating will be something like 60, 100, 150, or 200 amps. In rare instances, the main circuit breaker may be mounted at the bottom of the service panel.

How to install a circuit breaker panel?

Step 1. Open the cover of your breaker panel Step 2. Determine every circuit breaker’s amp rating Step 3. Add them all and get the load limit of the circuit breakers Step 4. Get the amperage for the electric panel

Can a branch circuit be added to an existing electrical panel?

If the total branch circuit pull exceeds the maximum capacity of the main line, it will trip the main circuit breaker, cutting off all electricity to the entire building. To determine whether another branch circuit can be added to an existing electrical panel, you must first calculate the remaining amount of unused amperage in the main line.

Guess what you want to know

-

How to eliminate the problem of small grid-connected battery in inverter of communication base station

How to eliminate the problem of small grid-connected battery in inverter of communication base station

-

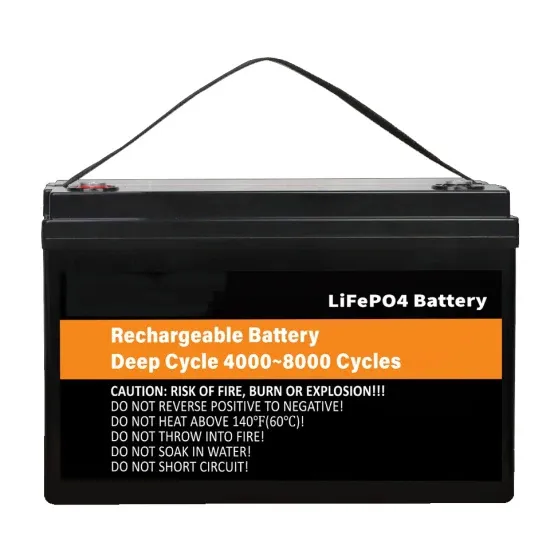

How to measure the grid-connected battery capacity of a communication base station inverter

How to measure the grid-connected battery capacity of a communication base station inverter

-

Vietnam 5G communication base station inverter grid-connected body

Vietnam 5G communication base station inverter grid-connected body

-

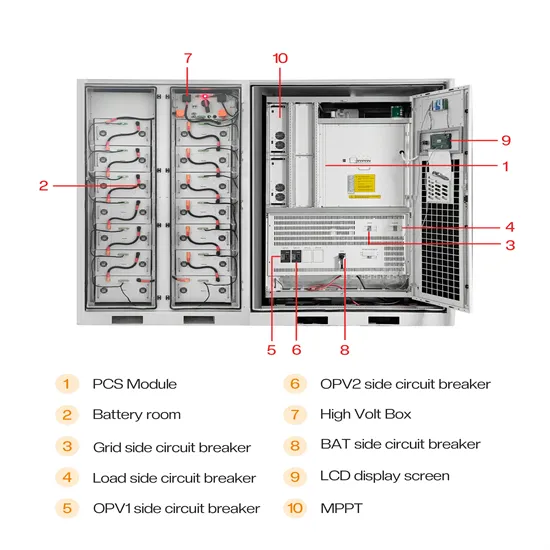

Communication base station inverter grid-connected access equipment

Communication base station inverter grid-connected access equipment

-

Huawei communication base station inverter grid-connected market share

Huawei communication base station inverter grid-connected market share

-

Does grid-connected installation of a communication base station inverter require any technical skills

Does grid-connected installation of a communication base station inverter require any technical skills

-

Power communication base station inverter grid-connected 4G to 3G

Power communication base station inverter grid-connected 4G to 3G

-

Zambia communication base station inverter grid-connected cabinet price

Zambia communication base station inverter grid-connected cabinet price

-

What are the communication base station inverter grid-connected projects in Tajikistan

What are the communication base station inverter grid-connected projects in Tajikistan

-

Domestic communication base station inverter grid-connected manufacturer

Domestic communication base station inverter grid-connected manufacturer

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.