How Battery Management Systems Operate and Their Essential Parts

Controllers and microprocessors act as the decision-making hub of a BMS. They process data collected by sensors to evaluate the battery''s health and remaining charge.

Get a quote

Compare 4 Types of BMS Topologies: Centralized vs

Limitations: Design Complexity: Integrating multiple battery management systems topologies can increase design complexity, requiring

Get a quote

How Battery Management Systems Operate and Their Essential

Controllers and microprocessors act as the decision-making hub of a BMS. They process data collected by sensors to evaluate the battery''s health and remaining charge.

Get a quote

Chapter 2 Battery Management Systems

Measured variable and parameter values and control commands are communicated between the parts of the BMS via a communication channel. This channel can be anything from a single

Get a quote

How to Design a Good Battery Management System

Introduction A battery management system (BMS) is an electronic system that manages a rechargeable battery pack. Its main functions are to monitor the

Get a quote

What is a Battery Management System (BMS)?

The BMS (Battery Management System) control method, as the central control idea of the battery, directly affects the service life of the battery, the safe operation of the

Get a quote

What Is a Battery Management System (BMS)?

A multi-master BMS allows multiple Battery Management Units (BMUs) to coordinate as peers within a battery system. Unlike traditional master-slave architectures,

Get a quote

What Is A Battery Management System (BMS)?

Key components of a Battery Management System include the battery monitoring unit (BMU), power management unit (PMU), protection circuit, communication interface, and

Get a quote

Battery Management System: Components, Types and Objectives

A battery management system (BMS) is a sophisticated control system that monitors and manages key parameters of a battery pack, such as battery status, cell voltage,

Get a quote

What is a Battery Management System (BMS)?

The BMS (Battery Management System) control method, as the central control idea of the battery, directly affects the service life of the battery,

Get a quote

Battery Management Systems (BMS) | Tutorials on Electronics

The development of software for Battery Management Systems (BMS) encapsulates a complex interplay of algorithms, system design, and data management, all pivotal for ensuring the

Get a quote

What are the Parts of a Battery Management System?

As the name suggests, a Battery Management System (BMS) is a system that helps manage a vehicle''s battery. The BMS is responsible for monitoring the battery''s state of

Get a quote

Technical Deep Dive into Battery Management System BMS

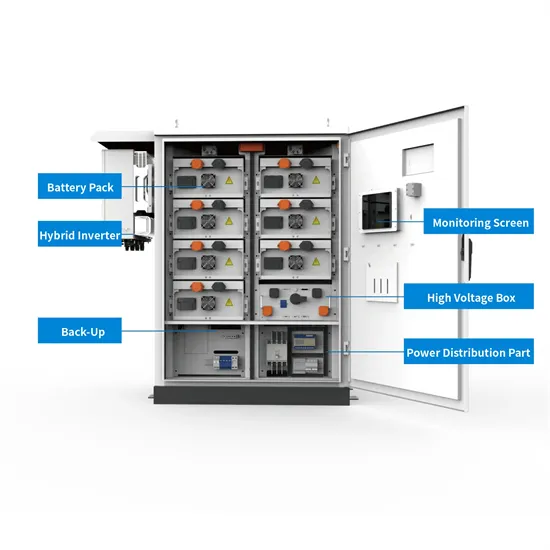

It is composed of two main sections: Low voltage and High voltage. High Voltage Section: In some designs, the high voltage section can be in a separate port and is responsible for the

Get a quote

Battery Management System (BMS): Diagrams & IC Selection

Key Functions of a Battery Management System (BMS) The core function of a BMS (Battery Management System) in electric vehicles is to coordinate five roles that together

Get a quote

What are the Parts of a Battery Management System?

In this article, we will discuss battery management systems, their purpose, architecture, design considerations for BMS, and future trends. Ask

Get a quote

Components of Battery Management System for Li-ion battery

Let us understand the key components of battery management system, different parts of battery management system, and battery management system architecture diagram.

Get a quote

Battery Management System (BMS) Detailed Explanation:

Battery Management System (BMS) is the "intelligent manager" of modern battery packs, widely used in fields such as electric vehicles, energy storage stations, and consumer

Get a quote

The Essential Guide to BMS Hardware And Its Key

BMS Hardware Design Considerations Several factors go into battery management system hardware design for a given application: Battery

Get a quote

What are the Parts of a Battery Management System?

A battery management system (BMS) is a device that monitors and manages the charging and discharging of a lithium-ion battery. It ensures that

Get a quote

Understand the BMS Components and Functions

In this blog, we''ll briefly introduce what battery management systems are, and explore the BMS components, and how they work to get the best performance from battery

Get a quote

Battery Management System Knowledge Paper on

Report Insight The growing dependence on battery pack energy storage for electric vehicles, stationary energy storage and other applications has underscored the importance of battery

Get a quote

Battery Management Systems (BMS): A Complete Guide

In this article, we will discuss battery management systems, their purpose, architecture, design considerations for BMS, and future trends. Ask questions if you have any

Get a quote

Four Main Types of Battery Management Systems

In this system, the BMS is divided into multiple modules, with each module responsible for managing a battery cell or battery pack. The modules are connected and coordinated through

Get a quote

How Does EV Battery Management System Work?

The EV battery management system is a critical component of any electric vehicle. It ensures that the batteries are adequately charged and

Get a quote

6 FAQs about [BMS battery management system is divided into several parts]

What are the components of a battery management system (BMS)?

A typical BMS consists of: Battery Management Controller (BMC): The brain of the BMS, processing real-time data. Voltage and Current Sensors: Measures cell voltage and current. Temperature Sensors: Monitor heat variations. Balancing Circuit: Ensures uniform charge distribution. Power Supply Unit: Provides energy to the BMS components.

What is a battery management system?

A battery management system is a vital component in ensuring the safety, performance, and longevity of modern battery packs. By monitoring key parameters such as cell voltage, battery temperature, and state of charge, the BMS protects against overcharging, over discharging, and other potentially damaging conditions.

What is a BMS control unit?

The control unit processes data collected from the battery and ensures that the system operates within its safe operating area. A critical part of the BMS, this system uses air cooling or liquid cooling to maintain the temperature of the battery cells.

What are the different types of battery management systems?

There are two primary types of battery management systems based on their design and architecture: Features a single control unit managing the entire battery pack. Simplifies data collection and control but may face scalability challenges for larger systems. Employs a modular architecture where smaller BMS units manage groups of battery cells.

Why should you use a battery management system (BMS)?

Performance optimization – By continuously tracking cell voltages, currents, and temperatures, the BMS can orchestrate precise charge/discharge control. This enables squeezing the maximum available capacity out of the battery pack without exceeding safe operating limits.

What is a battery charge monitoring system (BMS)?

The current limits act as a cut-off and prevent the battery from overcharging. This safeguards the cell voltages of the battery pack from high or low fluctuations, which immunes the battery life. The BMS consistently tracks the charge and discharge activities for the battery pack and monitors cell voltages.

Guess what you want to know

-

Bms battery management system products

Bms battery management system products

-

Lost communication with the BMS battery management system

Lost communication with the BMS battery management system

-

BMS battery management system price trend

BMS battery management system price trend

-

Swiss BMS battery management control system manufacturer

Swiss BMS battery management control system manufacturer

-

Easy-to-use lithium battery management system BMS

Easy-to-use lithium battery management system BMS

-

Bahrain BMS battery management system function introduction

Bahrain BMS battery management system function introduction

-

Lifeng BMS battery management system

Lifeng BMS battery management system

-

Chilean Battery Management System BMS

Chilean Battery Management System BMS

-

Lead-acid battery management bms

Lead-acid battery management bms

-

Is BMS battery management useful

Is BMS battery management useful

Industrial & Commercial Energy Storage Market Growth

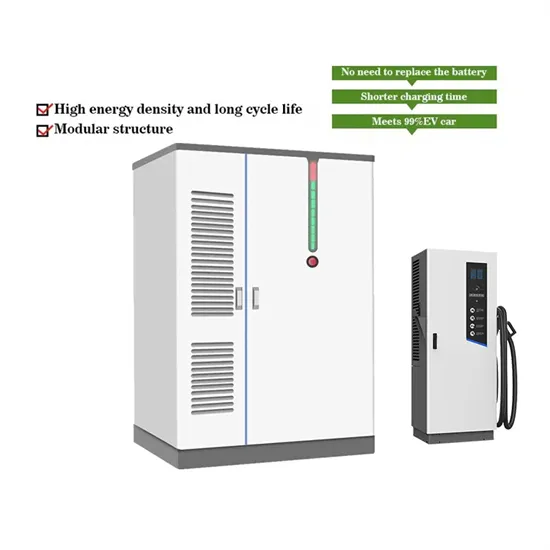

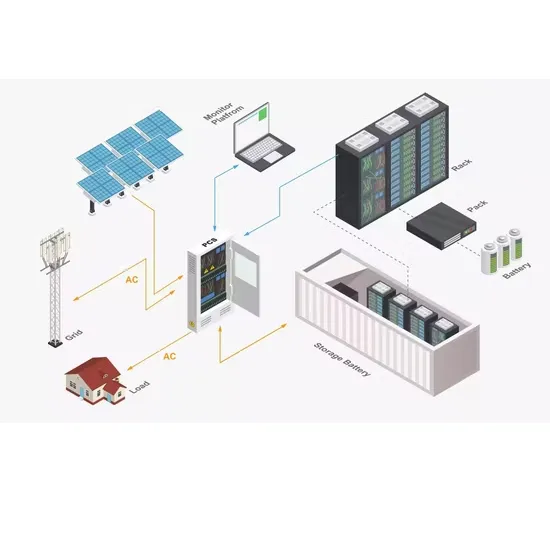

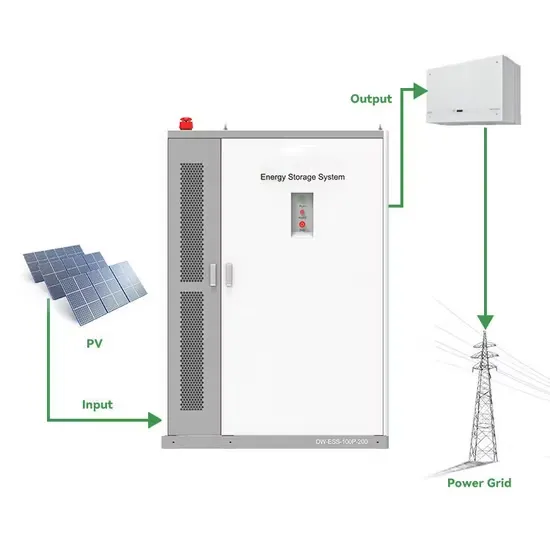

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.