Can a hybrid solar inverter be used with thin

In this blog, I''ll explore whether a hybrid solar inverter can be used with thin - film solar panels, and provide insights into the benefits and considerations of such a combination.

Get a quote

Solar PV module market outlook 2025: emerging

Poll 627 Responses Global PV module market outlook According to GlobalData''s Solar PV Modules and Inverters Market Trends and Analysis

Get a quote

Thin-film modules: Benefits and considerations in utility-scale solar

What are thin-film solar photovoltaic (PV) modules and what are the main considerations when using them in a utility-scale solar plant?

Get a quote

Thin-film solar panels: explained [UK, 2025]

What are thin-film solar panels? Thin-film solar panels, also known as flexible solar panels or stick-on solar panels, are a type of photovoltaic (PV)

Get a quote

Technical Note

Thin-film modules (as well as crystalline modules) may exhibit fault mechanisms that cause the modules to lose power over time. While crystalline modules can suffer from PID (Potential

Get a quote

Film Module

Thin-film modules can show a highly homogeneous surface appearance and very little variation from module to module. This allows the assembly of large, highly homogeneous panels on

Get a quote

Solar Panel vs Solar Inverter: Let''s Break It Down! | Discover Solar

When it comes to solar energy, think of panels as sun collectors and inverters as power translators. Panels convert sunlight into electricity, while inverters transform that into

Get a quote

Yaskawa Solectria working on new inverter model customized for

The goal is to create a version of its new SOLECTRIA XGI 1500-250 utility-scale string inverter that allows a grounded DC input, and thereby ensures optimal integration with

Get a quote

Thin-Film Solar Cells: Definition, Types & Costs

Thin-film Solar Panel Cost and Types. Amorphous Silicon, Cadmium Telluride, Copper Indium Gallium Selenide & Gallium arsenide

Get a quote

Yaskawa Solectria working on new inverter model

The goal is to create a version of its new SOLECTRIA XGI 1500-250 utility-scale string inverter that allows a grounded DC input, and thereby

Get a quote

Thin-Film Solar Panels: An In-Depth Guide | Types, Pros & Cons

When talking about solar technology, most people think about one type of solar panel which is crystalline silicon (c-Si) technology. While this is the most popular technology,

Get a quote

BIS Standards as applicable on Solar Modules in India

The Experts Committee made recommendation to make two separate Indian Standards for Crystalline and Thin Film based Modules by combining related standards,

Get a quote

Thin-film modules: Benefits and considerations in

What are thin-film solar photovoltaic (PV) modules and what are the main considerations when using them in a utility-scale solar plant?

Get a quote

Which inverter is the right one?

Afterwards, we focus on the most common problems in the area of PV modules and show a list of suitable combinations of PV modules and inverters that avoid these problems; organized by

Get a quote

Yaskawa Solectria Solar inverters to be optimized for

Solectria has formed a partnership with a prominent player in the U.S. manufacturing market: First Solar. The two are working together to

Get a quote

Thin-Film Solar: Applications And Efficiency

Because thin-film solar modules are flexible and light, they''re perfect for portable solar chargers that power devices on-the-go. They''re

Get a quote

Guided Path Solar forms distribution partnership with

"Guided Path Solar is driven by a desire for a more sustainable and responsible solar industry, making this partnership one with shared core

Get a quote

Yaskawa Solectria Solar inverters to be optimized for First Solar thin

Solectria has formed a partnership with a prominent player in the U.S. manufacturing market: First Solar. The two are working together to optimize the Solectria XGI

Get a quote

Which inverter is the right one?

Afterwards, we focus on the most common problems in the area of PV modules and show a list of suitable combinations of PV modules and inverters that

Get a quote

Special inverters required for thin film panels?

I''ve recently been looking into installing some thin film panels on my house, but have noticed that there are large differences in the open circuit voltage of thin film and

Get a quote

120522_Wechselrichter+Module EN

Due to the growing number of new module technologies (e.g. thin-film technology), it is becoming increasingly important to take special module and inverter features into account during the

Get a quote

2022 product catalogue-A

JinkoSolar has built a vertically integrated solar product value chain, with an integrated annual capacity of 31 GW for mono wafers, 19 GW for solar cells, and 36 GW for solar modules, as of

Get a quote

Best Solar Panels with Inverter: Thin Film vs Cell Panel | thlinksolar

Compare thin film and solar cell panels with inverter options. Discover the best solar panel combinations from thlinksolar for every application.

Get a quote

Inverters help combat PID as solar technology evolves

Thin-film modules are more susceptible to PID because of their higher voltage and material makeup, but crystalline silicon panels are also at risk if there are any flaws in the

Get a quote

Thin-Film Solar Panels: An In-Depth Guide | Types, Pros & Cons

I''ve recently been looking into installing some thin film panels on my house, but have noticed that there are large differences in the open circuit voltage of thin film and

Get a quote

6 FAQs about [Solar thin film module inverter]

What are thin-film solar panels?

Thin-film solar panels use a 2 nd generation technology varying from the crystalline silicon (c-Si) modules, which is the most popular technology. Thin-film solar cells (TFSC) are manufactured using a single or multiple layers of PV elements over a surface comprised of a variety of glass, plastic, or metal.

What are thin-film photovoltaic (PV) modules?

Thin-film photovoltaic (PV) modules are among the main alternatives to silicon modules in commercial solar energy systems. Thin-film technologies account for a small but growing share of the global solar market and are expected to grow at a compound annual growth rate of 23% from 2020-2025.

Why are thin-film solar panels better than silicon solar panels?

Since fewer thin-film modules can be connected in series to build a single string, requiring more strings, it is recommended to place an intermediate step between the string and the collector to reduce the number of inputs to the inverter. Thin-film solar panels are lightweight as they use less semiconductor materials than silicon panels.

What materials are used for thin-film solar technology?

The most commonly used ones for thin-film solar technology are cadmium telluride (CdTe), copper indium gallium selenide (CIGS), amorphous silicon (a-Si), and gallium arsenide (GaAs). The efficiency, weight, and other aspects may vary between materials, but the generation process is the same.

Why are thin-film solar panels more suitable in humid locations?

Humidity has an impact on the distribution, making thin-film modules more suitable in humid locations. When designing solar energy systems using thin-film panels, project designers need to calculate the spectral correction based on air mass and precipitable water. Recombination losses .

How efficient are CdTe thin-film solar panels?

CdTe thin-film solar panels reached a 19% efficiency under Standard Testing Conditions (STC), but single solar cells have achieved efficiencies of 22.1%. This technology currently represents 5.1% of the market share worldwide, falling second only under crystalline silicon solar panels that hold 90.9% of the market.

Guess what you want to know

-

Croatia Solar Inverter Module

Croatia Solar Inverter Module

-

How many small solar panels are needed for a 2kw water pump inverter

How many small solar panels are needed for a 2kw water pump inverter

-

Wind-solar hybrid solar inverter

Wind-solar hybrid solar inverter

-

Sri Lanka Solar PV Inverter

Sri Lanka Solar PV Inverter

-

Cambodia photovoltaic module inverter manufacturer

Cambodia photovoltaic module inverter manufacturer

-

General home solar inverter

General home solar inverter

-

Australia customized solar water pump inverter transformation

Australia customized solar water pump inverter transformation

-

Solar water pump inverter fully automatic high power

Solar water pump inverter fully automatic high power

-

Solar cell inverter installation

Solar cell inverter installation

-

Solar water pump inverter has water

Solar water pump inverter has water

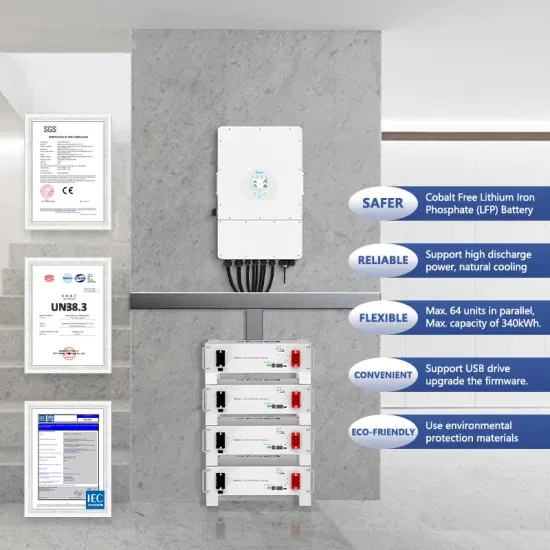

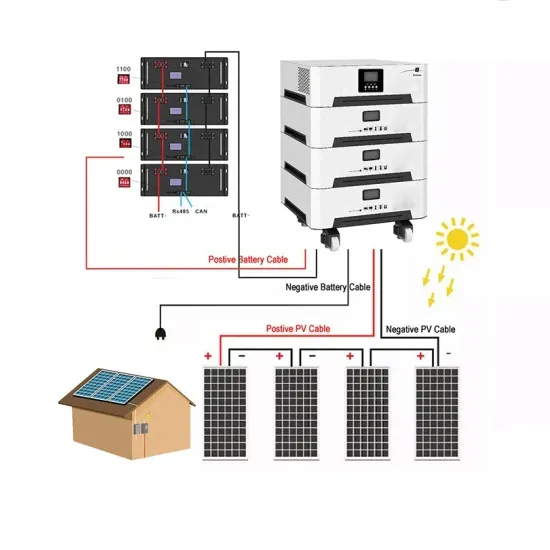

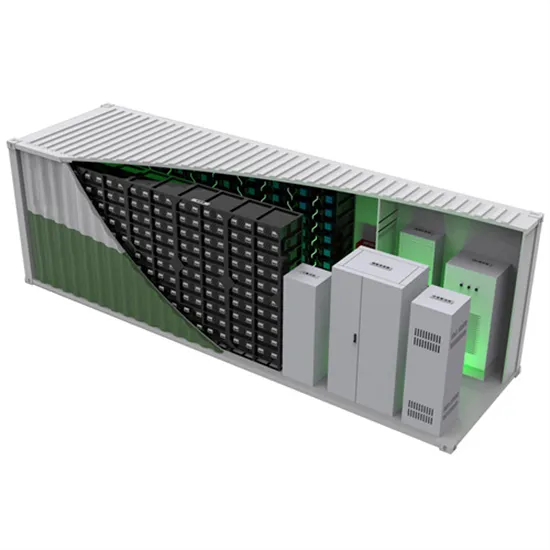

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.