Microsoft Word

• How many solar panels the inverter must control. It''s always better to buy an inverter that is too big for your needs, rather than one equal to, or too small. If you overload the inverter it will trip,

Get a quote

How many solar panels do I need to run a 0.75 HP pump?

To run a 0.75 HP solar water pump efficiently, you''ll typically need 4 to 6 solar panels of 250W each, depending on sun hours and system efficiency. Don''t stop here—let''s break down why

Get a quote

What Inverter Size Do I Need to Run a Kettle?

Boiling water in a kettle is something almost all of us do, so much that we take it for granted. We just put water in and wait for it to boil. But if you use solar power every watt counts, so what

Get a quote

What Size Solar Panel for Well Pump: Comprehensive Sizing Guide

Based on our calculations and real-world conditions, you would need approximately 18 solar panels, each rated at 300 watts, to sufficiently power your well pump

Get a quote

How Many Solar Panels Do You Need to Run a 1 HP

Knowing how many solar panels you''ll need is key to making sure it''s efficient and cost-effective. This guide breaks it down for you, so you can make the best

Get a quote

What size solar panel do I need to run a water pump?

The size of the solar panel will vary depending on the pump that best fits your needs. The number of solar panels will depend on the wattage that a particular pump will need to operate, the

Get a quote

How many solar panels required for 2kw? –

The number of solar panels required for a 2kW system depends on a number of factors, including the size and efficiency of the panels, the amount of sunlight the panels receive, and the

Get a quote

Solar Water Pump Sizing Calculator

Think about how much water you need, the pump''s capacity, and the size of the solar panels. Getting these right is key to picking the right pump for your needs.

Get a quote

How Many Panels Do You Need To Run A Solar Pump? | Demystifying Solar

The number of solar panels needed to run a solar pump depends on the type and size of the pump, if you want to make sure you get the right sizing and pricing click here.

Get a quote

How Many Solar Panels Do You Need to Run a Water Pump?

4 days ago· To run a water pump on solar, multiply the pump''s power by 1.5 to calculate the total solar panel wattage needed. For example, a 1000W pump requires at least 1500W of solar

Get a quote

What Type of Solar Panel Do You Need for a Water

For a 1 HP Water Pump: Typically, you need around twelve 100-watt solar panels, totaling 1200 watts. For a 2 HP Water Pump: You might

Get a quote

How many solar panels are needed for 2kw solar power generation

To generate 2kW, one must first consider the wattage of the panels being used. If utilizing 300W panels, a calculation of total wattage needed will reveal that a minimum of

Get a quote

Solar Inverter Sizing Calculator: Important Guide

This comprehensive guide will walk you through solar inverter sizing, explain its importance, and help you understand how to use a solar

Get a quote

How Many Panels Do You Need To Run A Solar Pump?

The number of solar panels needed to run a solar pump depends on the type and size of the pump, if you want to make sure you get the right sizing and pricing click here.

Get a quote

How many solar panels are needed for 2kw solar

To generate 2kW, one must first consider the wattage of the panels being used. If utilizing 300W panels, a calculation of total wattage needed will

Get a quote

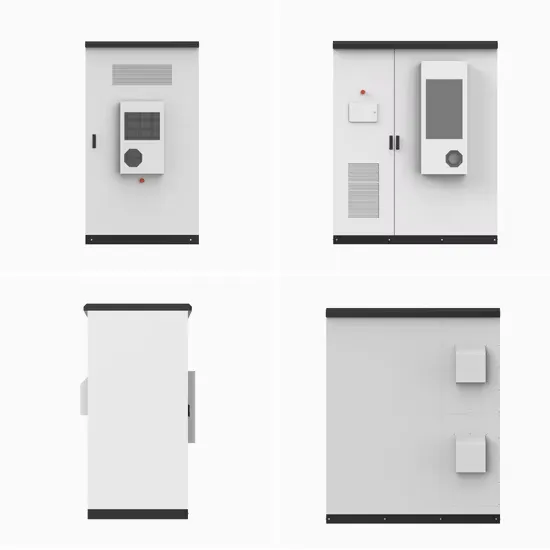

A Typical Design of Solar Water Pump System | inverter

2. Solar pump inverter Generally, it is better to select an inverter that is larger than the water pump one size in the specification. The 1.5KW water pump is equipped with a

Get a quote

Sizing Forms | Tripple Hydro and Energy Renewables

Complete our sizing forms to accurately determine the power, infrastructure, and energy needs for your solar, generator, pump, VSD, Pivot Master, and hydro

Get a quote

How Many Solar Panels Can I Connect to an Inverter?

As the temperature increases, it reduces the amount of energy a panel produces – on hot, sunny days, the voltage may be significantly

Get a quote

How Many Solar Panels To Power A Water Pump?

The size of the solar panel system required to power a well pump depends on several factors, including the pump''s horsepower rating and daily energy needs. As a rule of

Get a quote

What Size Inverter Do I Need?

Learn how to calculate what size inverter you need with The Inverter Store''s handy guide. We make the process straightforward for you to fit your exact

Get a quote

What Type of Solar Panel Do You Need for a Water Pump?

For a 1 HP Water Pump: Typically, you need around twelve 100-watt solar panels, totaling 1200 watts. For a 2 HP Water Pump: You might need about 24 panels, depending on

Get a quote

How Many Solar Panels Do You Need to Run a 1 HP Water Pump?

Knowing how many solar panels you''ll need is key to making sure it''s efficient and cost-effective. This guide breaks it down for you, so you can make the best decisions for your solar water

Get a quote

How Many Solar Panels Do I Need to Run a Water Pump?

How many solar panels do you need for a water pump? You will also get a table of contents by which you can measure the number of solar panels needed for different wattages

Get a quote

Size your solar system

Inverter sizing In many systems, the inverter is sized to be smaller than the panel output. For example, a 6.6 kW solar system is often paired with a 5 kW inverter. Because the panels are

Get a quote

6 FAQs about [How many small solar panels are needed for a 2kw water pump inverter ]

How much solar power does a water pump need?

First, you need to know the pump’s power requirement, which is typically measured in watts (W). Divide the pump’s wattage by the average peak sunlight hours your location receives daily. For example, if your pump requires 1500W and you get 5 sunlight hours per day, you would need at least a 300W solar panel.

How many solar panels does a well pump need?

3.81 kW 250 watts = 18 panels Based on our calculations and real-world conditions, you would need approximately 18 solar panels, each rated at 300 watts, to sufficiently power your well pump while accounting for various efficiency losses. Understanding the energy needs of your water pump is critical.

How many solar panels do I need to run a pump?

The number of solar panels needed to run a pump depends on the type of pump you have. There are two main classes of pumps: Pumps Designed for Solar: These pumps are slightly more efficient and can run on anywhere from 200 watts (two 100-watt panels) to around 800 or 1,200 watts of power.

What type of solar panel do I need for my water pump?

For water pumps, monocrystalline and polycrystalline panels are generally recommended due to their higher efficiency and reliability. The power requirement of your water pump is one of the most critical factors in determining the type of solar panel you need. The power requirement is usually measured in watts (W) and depends on factors such as:

Where can I install a solar-powered water pump?

You can install a solar-powered water pump at any place with sunlight available because sunlight is the source of solar energy. It has fewer accessories and easy-to-install options. Some water pumps come with built-in solar panels and batteries along with a control box. You can also connect solar-powered water pumps with the existing solar system.

How to choose a water pump for a solar array?

After figuring out the solar array size, pick the right pump. Look at your water needs and the pressure. Choose a pump that can handle your daily water use and fits with the solar array. The number of solar panels needed to run a 1 hp water pump changes with the system’s details.

Guess what you want to know

-

18 How many watts of water pump inverter are suitable for solar panels

18 How many watts of water pump inverter are suitable for solar panels

-

What solar panels are needed for a 25w water pump inverter

What solar panels are needed for a 25w water pump inverter

-

Small 24-hour solar water pump inverter

Small 24-hour solar water pump inverter

-

Connecting solar panels to water pump inverter

Connecting solar panels to water pump inverter

-

Buy a small solar water pump inverter

Buy a small solar water pump inverter

-

Can solar panels power a 12V water pump inverter

Can solar panels power a 12V water pump inverter

-

How much does a solar water pump inverter cost in Nauru

How much does a solar water pump inverter cost in Nauru

-

How many water pump inverters can be installed with solar panels

How many water pump inverters can be installed with solar panels

-

How big a solar panel should I use for a 24w water pump inverter

How big a solar panel should I use for a 24w water pump inverter

-

Can solar panels and 12v water pump inverter be used together

Can solar panels and 12v water pump inverter be used together

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.