A technical review of modern traction inverter systems used in

These structures'' key characteristics, which make them ideal for the upcoming generation of traction inverters, include low-output current distortion, dv / dt reduction,

Get a quote

How to Set Battery Cutoff Voltage on Your Inverter

In this video, we provide a comprehensive step-by-step guide on how to set the battery cutoff voltage on your inverter using the @felicitysolar 3.5KVA, 24V IVPS pure sinewave inverter.

Get a quote

Harmonics in Photovoltaic Inverters & Mitigation Techniques

These power electronic devices are called inverters. Inverters are mainly used to convert direct current into alternating current & act as interface between renewable energy & grid. Inverter

Get a quote

How to Choose the Right Inverter Battery Voltage for Your Needs

Understanding inverter battery voltage is key to creating a strong and dependable power system. This detailed guide explores how to choose the right voltage, offers tips for

Get a quote

How to Safely Connect a Battery to an Inverter: A

Learn how to safely connect your batteries to your inverter with our guide. Avoid common wiring mistakes to optimize performance and extend

Get a quote

Battery Sizing Calculation | Solved Example

Learn about battery sizing calculation for applications like Uninterrupted Power Supply (UPS), solar PV systems, telecommunications, and other auxiliary

Get a quote

Voltage drop between battery and inverter

If there is a 0.7 volt drop in the battery to inverter at 1 amp there is a connection or crimp issue. Keep poking with the voltmeter until the drop is found.

Get a quote

5. Operation

The inverter will automatically restart, after a minimum delay of 30 seconds, when the battery voltage has increased above the "Low battery restart" parameter. After three restarts, followed

Get a quote

Battery connection for inverter

This article enlightens the features, risks and connectivity of inverter and the battery along with specific safety measures, its hazards and troubleshooting strategies.

Get a quote

connecting an inverter: spark prevention / reduction

when I attach an inverter (turned off, unloaded) to my battery system there is an inevitable inrush of voltage to fill the capacitor. I wonder

Get a quote

How To Reduce Electricity Bill With Invertek Inverters

Key Terms to Know: Battery Efficiency: A higher-efficiency battery reduces electricity loss. Standby Mode: Quality inverters like Invertek minimize power drawn while in standby mode.

Get a quote

How to Efficiently Reduce 48 Volts to 12 Volts

Check out our article "How to Reduce 24 Volts to 12 Volts" for detailed guidance. Understanding Voltage Reduction In a 48v to 12v System Reducing voltage from 48V to 12V

Get a quote

How To Reduce Battery Voltage

Sometimes, your electronics project might just need a voltage source that''s lower than the battery voltage you have available. When this happens, you can reduce your battery''s

Get a quote

Maximizing Energy Efficiency: How to Use an Inverter

Select an inverter that matches your power requirements to ensure optimal efficiency. Oversizing the inverter can lead to energy wastage and reduce its

Get a quote

Common-Mode Voltage in Inverters: Effects and Reduction Methods

While a two-level inverter converts DC to AC, it generates total harmonic distortion (THD) and common-mode voltage. The common-mode voltage in inverters is harmful to the

Get a quote

Inverter Battery Connection: Essential Tips For Safe And Efficient

Learn essential tips for safe and efficient inverter battery connection. Discover step-by-step guides, wiring techniques, and troubleshooting tips to optimize your power backup system''s

Get a quote

How to Set Battery Cutoff Voltage on Your Inverter

In this video, we provide a comprehensive step-by-step guide on how to set the battery cutoff voltage on your inverter using the @felicitysolar 3.5KVA, 24V IVPS pure

Get a quote

How to Safely Connect a Battery to an Inverter: A Step-by-Step

Learn how to safely connect your batteries to your inverter with our guide. Avoid common wiring mistakes to optimize performance and extend system life.

Get a quote

Increase the range of EV with the same battery

These vehicles share a same and unique DC-Link voltage, i.e. the battery voltage, the input voltage of the inverter and the maximum phase voltage of

Get a quote

Inverter Battery Voltage: How Many Volts Are Needed For

Optimal battery voltage enhances inverter functionality. It helps ensure the inverter delivers the necessary wattage without excessive strain. Furthermore, maintaining appropriate

Get a quote

SolarEdge Inverters, Power Control Options — Application Note

Select RRCR Choose Enable or Disable Press Enter In addition to enabling this option, the inverter must be connected to a power reduction device. For RRCR connectivity, refer to the

Get a quote

A Review of Multilevel Inverter Topologies in Electric

This paper presents an investigation of the advantages and disadvantages of higher DC-link voltage in traction inverters, as well as a

Get a quote

connecting an inverter: spark prevention / reduction

when I attach an inverter (turned off, unloaded) to my battery system there is an inevitable inrush of voltage to fill the capacitor. I wonder what is the best way to do this and

Get a quote

Second harmonic current reduction of dual active bridge

Dual active bridge (DAB) DC/DC converters are widely favored for integration into two-stage inverters due to their advantageous features, such as galvanic isolation,

Get a quote

Low Battery and Overload Protection Circuit for Inverters

A very simple low battery cut-off and overload protection circuit has been explained here. The figure shows a very simple circuit set up which

Get a quote

6 FAQs about [Battery voltage reduction to inverter]

How can a power inverter improve battery performance?

Ensuring the inverter is switched off when not needed can prevent unnecessary battery usage. Regularly checking and maintaining the battery’s health can extend its lifespan and efficiency. Understanding the inverter’s power requirements and matching them with the battery’s capacity can further optimize performance.

Why are Inverter Batteries important?

Inverter batteries are crucial for power backup. They need proper care. Battery management ensures they last longer and perform well. You can avoid frequent replacements. Let’s explore more about keeping your inverter battery healthy. Healthy batteries provide consistent power supply. They reduce chances of sudden power loss.

Do inverters and batteries need to match?

The inverter and batteries must match in terms of voltage, capacity, and power output. If you are using a 12V battery, then the input voltage of the inverter must match the battery voltage. If the specifications of the battery and the inverter do not match, the system will not operate stably and may even damage the equipment.

What are the problems with Inverter Batteries?

Inverter batteries can face several problems. Identifying these issues early helps in battery management. Here are some common problems: Overcharging: This can damage the battery. It reduces its life. Undercharging: The battery doesn’t get enough charge. It affects performance.

Can a 12V battery be used as an inverter?

If you are using a 12V battery, then the input voltage of the inverter must match the battery voltage. If the specifications of the battery and the inverter do not match, the system will not operate stably and may even damage the equipment. In addition, choose the right inverter power and battery capacity for your home or commercial needs.

What are inverter battery connections?

Inverter battery connections form the backbone of reliable power systems, ensuring efficient operation and safety. By following best practices and understanding the nuances of these connections, you can enhance system performance and longevity.

Guess what you want to know

-

High voltage battery connected to inverter

High voltage battery connected to inverter

-

Can I use an inverter if the battery voltage is low

Can I use an inverter if the battery voltage is low

-

Solar Lithium Battery Water Pump Inverter

Solar Lithium Battery Water Pump Inverter

-

Inverter upper and lower voltage

Inverter upper and lower voltage

-

Inverter voltage keeps increasing

Inverter voltage keeps increasing

-

Marshall Islands 30kw lithium battery energy storage system inverter

Marshall Islands 30kw lithium battery energy storage system inverter

-

Inverter output voltage returns to zero

Inverter output voltage returns to zero

-

How much does a battery plus inverter cost

How much does a battery plus inverter cost

-

Self-generating inverter voltage exceeds limit

Self-generating inverter voltage exceeds limit

-

Inverter voltage space vector control

Inverter voltage space vector control

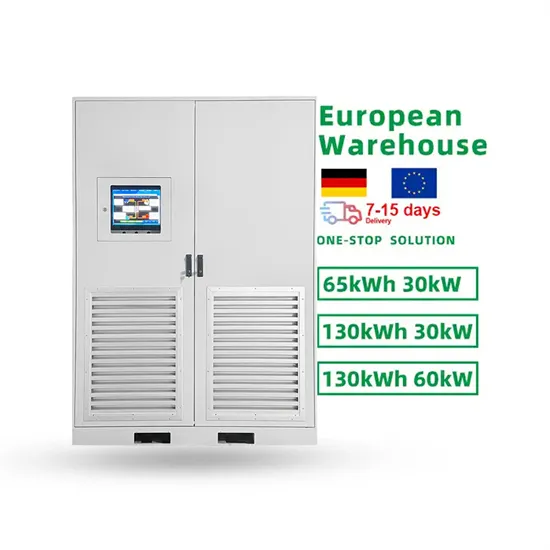

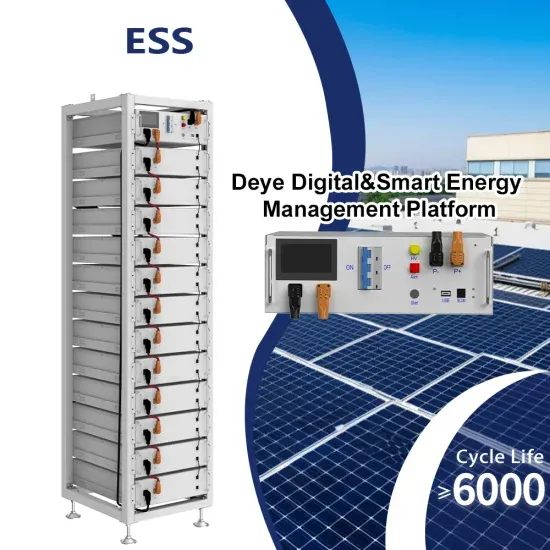

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.