Frequency vs High-Frequency Inverters: The Best Choice for Off

With outstanding shock resistance, stable inductive load performance, and long lifespan, frequency inverters are the optimal choice for off-grid applications. Importers should prioritize

Get a quote

Technical comparison between Low Frequency

Low-frequency inverters have the advantage over high-frequency inverters in two fields: peak power capacity, and reliability. Low-frequency inverters are

Get a quote

Comparing High-Frequency vs. Low-Frequency Inverters

Inverters are essential components of many electrical systems, converting direct current (DC) into alternating current (AC) to power various devices and

Get a quote

Why Frequency Inverters Are More Suitable for Off-Grid

In summary, power frequency inverters have become the only choice for off-grid solar systems with their excellent impact resistance, stable inductive load support and ultra-long service life.

Get a quote

The difference between high frequency inverter and

On the other hand, low frequency inverters are known for their durability and reliability, making them a preferred choice for heavy-duty or

Get a quote

Harmonic Overload: Impacts Of High-Frequency

During the CIGRE Grid of the Future symposium and workshop, harmonics were recognized as a critical focus in modern electrical systems, where high

Get a quote

Low Frequency Inverters

"Low frequency power inverters got the name of "low frequency" because they use high speed power transistors to invert the DC to AC, but drive transistors at the same

Get a quote

Which Is Better Low Frequency or High-Frequency Inverter

The document compares low frequency inverters, which operate near power line frequencies, to high frequency inverters, which use much higher switching frequencies. Low frequency

Get a quote

Low Frequency VS High Frequency Inverter

Discover the differences between low-frequency and high-frequency off-grid inverters, their efficiency, weight, and ideal applications for your solar system.

Get a quote

Everything to Know Low Frequency Inverters

However, low-frequency inverters are more robust, handle surge currents better, and provide better electrical isolation, making them suitable for high-reliability

Get a quote

Demystifying High Frequency vs Low Frequency Inverters/UPS

The main difference between High-frequency and Transformer-based Low-Frequency Inverters/UPS is the frequency at which they operate. High-frequency

Get a quote

Understanding Low Frequency Power Inverters

Applications and Benefits: Why Use Low Frequency Power Inverters? Low frequency power inverters offer several benefits over their high frequency counterparts, including: – Higher

Get a quote

Low Frequency vs High Frequency Inverters: Which

There are two main types of frequencies to be compared: low frequency vs high frequency inverters. The inverter frequency determines the desired

Get a quote

LF vs HF Inverter

Like, LF inverters are great for sensitive electronics ''cause they deliver cleaner power, but they''re pricier. HF inverters are cheaper and smaller, good for regular stuff, but

Get a quote

Technical comparison between Low Frequency Inverter VS high Frequency

Low-frequency inverters have the advantage over high-frequency inverters in two fields: peak power capacity, and reliability. Low-frequency inverters are designed to deal with higher power

Get a quote

Low frequency inverter vs high frequency inverter

If your application involves powering large appliances with high surge loads, a low-frequency inverter is the best choice. However, if you are looking for a lightweight, efficient,

Get a quote

Low frequency inverter vs high frequency inverter

If your application involves powering large appliances with high surge loads, a low-frequency inverter is the best choice. However, if you are

Get a quote

Solar high frequency vs low frequency inverter

Whether you need a low frequency inverter or a high frequency inverter, welcome to contact Xindun Power, my friends. Related posts. There are many types of inverters, solar inverter

Get a quote

Power Frequency Inverter vs High-Frequency Inverter

Here, we will provide a detailed comparison and analysis of these two inverters from multiple scenarios and perspectives to better understand power-frequency inverters and

Get a quote

High-Frequency vs. Low-Frequency Inverters

The inverter steps up the voltage using lightweight transformers or inductors, followed by the conversion to AC. Low-Frequency Inverters: Low-frequency inverters use heavy, iron-core

Get a quote

low frequency inverter better for fully

hey folks! i recently electrified my house - heat pump for heating and cooling, heat pump for water heater. grid tied 10kW roof solar panels with battery backup, want to prepare

Get a quote

Low-Frequency vs. High-Frequency Inverters: Which

Choosing the right inverter is key to maximizing your solar system''s efficiency. Explore the differences between high-frequency and low-frequency

Get a quote

Low-Frequency vs. High-Frequency Inverters: Which One is

Choosing the right inverter is key to maximizing your solar system''s efficiency. Explore the differences between high-frequency and low-frequency inverters, and discover

Get a quote

Frequency vs High-Frequency Inverters: The Best Choice for Off-Grid

With outstanding shock resistance, stable inductive load performance, and long lifespan, frequency inverters are the optimal choice for off-grid applications. Importers should prioritize

Get a quote

Complete Comparison: High Frequency vs Low Frequency Inverters

High-frequency inverters work at 20–100 kHz and are compact, light, and efficient. Low-frequency inverters work around 50–60 Hz and are built to handle larger loads and harsh

Get a quote

High frequency vs low frequency pure sine wave

By definition, Low frequency power inverters got the name of "low frequency" because they use high speed power transistors to invert the DC

Get a quote

Learn About High vs. Low Frequency Inverters: Which

High-frequency inverters and low-frequency inverters are two common types of inverters. They have significant differences in their operation

Get a quote

Low Frequency vs High Frequency Inverters: Which One Is Best?

There are two main types of frequencies to be compared: low frequency vs high frequency inverters. The inverter frequency determines the desired application''s compatibility, efficiency,

Get a quote

Learn About High vs. Low Frequency Inverters: Which is Right for

High-frequency inverters and low-frequency inverters are two common types of inverters. They have significant differences in their operation and characteristics, and the

Get a quote

LF vs HF Inverter

Like, LF inverters are great for sensitive electronics ''cause they deliver cleaner power, but they''re pricier. HF inverters are cheaper and smaller, good for regular stuff, but might not be as

Get a quote

6 FAQs about [Which is better for off-grid inverters power frequency or high frequency ]

Are low-frequency inverters more powerful than high-frequency inverters?

Low-frequency inverters have much greater peak power capacity to handle large loads with power spikes than high-frequency inverters.

What is a high frequency inverter?

Applications: These inverters are more suitable for off-grid systems where heavy loads and extreme conditions are expected, such as in industrial applications or in remote locations with harsh environments. Weight: High-frequency inverters are lighter than low-frequency inverters, using smaller, lighter transformers.

What internal frequency do inverters operate at?

What internal frequency the inverter circuits operate at – low frequency or high frequency (not to be confused with AC power output frequency which is a standard 50Hz for our inverters). Low-frequency inverters have the advantage over high-frequency inverters in two fields: peak power capacity, and reliability.

How do I choose the right inverter for my off-grid Solar System?

The choice between a low-frequency and high-frequency inverter will depend on your specific needs, such as the type of loads you expect to power and the conditions in which your off-grid system will operate. Considering these factors is essential when choosing the suitable inverter for your off-grid solar system.

Should you buy a high-frequency inverter?

On the other hand, if you’re looking for a portable solution for RVs, boats, or small solar setups, a high-frequency inverter is ideal for powering lighter loads, such as laptops, LED lights, and small electronics.

Can a high frequency inverter sustain with the same frequency?

But high frequency inverters cannot sustain with the same. electronics components with complex design circuits in case of inverter failure you have to replace complete electronics PPCB, which cost is approx 80% of new inverter.

Guess what you want to know

-

Which energy storage inverter is better power frequency or high frequency

Which energy storage inverter is better power frequency or high frequency

-

Which portable variable frequency power supply is better

Which portable variable frequency power supply is better

-

Albanian power frequency off-grid inverter merchants

Albanian power frequency off-grid inverter merchants

-

5kva high frequency power inverter

5kva high frequency power inverter

-

Austria power frequency off-grid inverter

Austria power frequency off-grid inverter

-

Columbia horizontal power frequency off-grid inverter

Columbia horizontal power frequency off-grid inverter

-

India horizontal power frequency off-grid inverter

India horizontal power frequency off-grid inverter

-

Dominican off-grid power frequency 10kw inverter

Dominican off-grid power frequency 10kw inverter

-

Which outdoor power supply in Indonesia is better to use

Which outdoor power supply in Indonesia is better to use

-

Ireland Power Frequency Off-Grid Inverter

Ireland Power Frequency Off-Grid Inverter

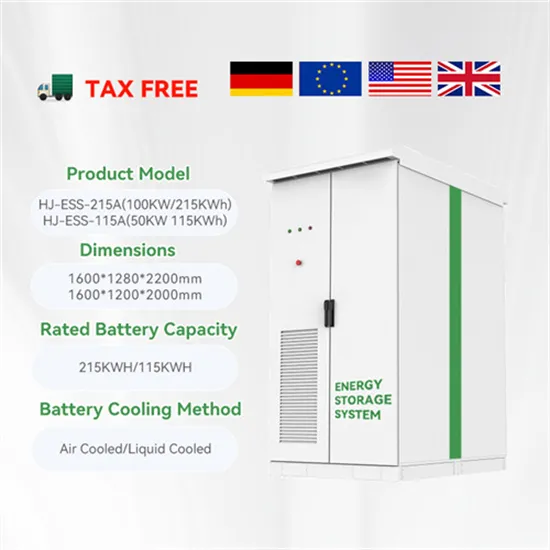

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

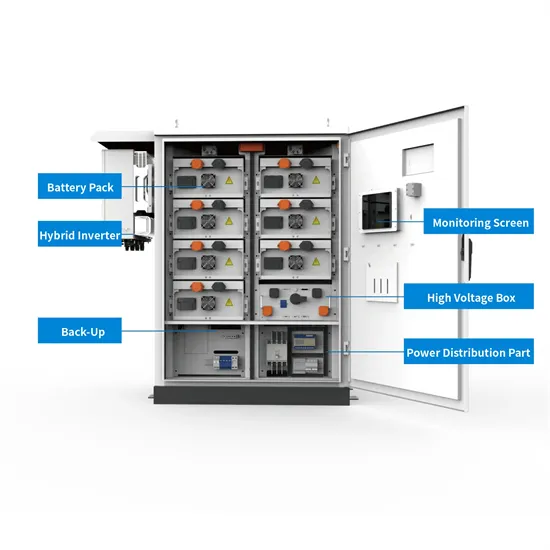

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.