Flywheel Energy Storage System: What Is It and How

In a flywheel energy storage system, electrical energy is used to spin a flywheel at incredibly high speeds. The flywheel, made of durable materials like

Get a quote

What is flywheel energy storage?

In the charging mode, the power electronics unit converts the AC from the grid to DC and sends it to the motor/generator, which spins the flywheel to a high speed, storing

Get a quote

The Status and Future of Flywheel Energy Storage

The MG must be brush-less, with AC current being generated by the inverter for motoring, and then AC current is converted back to DC in generator mode. In most cases, the MG is

Get a quote

Flywheel Energy Storage System: What Is It and How Does It

In a flywheel energy storage system, electrical energy is used to spin a flywheel at incredibly high speeds. The flywheel, made of durable materials like composite carbon fiber, stores energy in

Get a quote

Flywheel Energy Storage

Advances in power electronics, magnetic bearings, and flywheel materials coupled with innovative integration of components have resulted in direct current (DC) flywheel energy storage

Get a quote

Review of Flywheel Energy Storage Systems structures and

Flywheel Energy Storage System (FESS) is an electromechanical energy storage system which can exchange electrical power with the electric network. It consists of an

Get a quote

Flywheel Energy Storage System

A Flywheel UPS energy storage system uses stored kinetic energy that is transformed into DC power. The DC power is sent to the UPS that converts the DC energy into

Get a quote

Hierarchical control of DC micro-grid for photovoltaic EV charging

In this paper, the DC micro-grid system of photovoltaic (PV) power generation electric vehicle (EV) charging station is taken as the research object, proposes the hybrid

Get a quote

Design and Research of a New Type of Flywheel Energy Storage

The proposed flywheel energy storage system, depicted in Fig. 1, utilizes a permanent magnet electrodynamic suspension. The permanent magnet acts as the magnetic

Get a quote

Artificial intelligence computational techniques of flywheel energy

However, the intermittent nature of these RESs necessitates the use of energy storage devices (ESDs) as a backup for electricity generation such as batteries,

Get a quote

Low voltage ride through of a flywheel energy storage system with

For stabilizing the power grid during voltage dips, a doubly fed induction machines (DFIM)-based flywheel energy storage system is applied in this paper. The reactive power

Get a quote

The High-speed Flywheel Energy Storage System

A flywheel energy storage system converts electrical energy supplied from DC or three-phase AC power source into kinetic energy of a spinning mass or converts kinetic energy of a spinning

Get a quote

Applications of flywheel energy storage system on load frequency

Flywheel energy storage systems (FESS) are considered environmentally friendly short-term energy storage solutions due to their capacity for rapid and efficient energy storage

Get a quote

Critical Review of Flywheel Energy Storage System

This review presents a detailed summary of the latest technologies used in flywheel energy storage systems (FESS). This paper covers the types

Get a quote

(PDF) Implementation and Control of an AC/DC/AC

An all-electric driveline based on a double wound flywheel, connected in series between main energy storage and a wheel motor, is presented. The flywheel works as a

Get a quote

The High-speed Flywheel Energy Storage System

A flywheel energy storage system converts electrical energy supplied from DC or three-phase AC power source into kinetic energy of a spinning mass or converts kinetic energy of a spinning

Get a quote

Review of Flywheel Energy Storage Systems structures and applications

Flywheel Energy Storage System (FESS) is an electromechanical energy storage system which can exchange electrical power with the electric network. It consists of an

Get a quote

A Review of Flywheel Energy Storage System Technologies

One such technology is flywheel energy storage systems (FESSs). Compared with other energy storage systems, FESSs offer numerous advantages, including a long lifespan,

Get a quote

Design of an improved adaptive sliding mode observer for charge

Accordingly, an improved adaptive sliding mode observer algorithm for the charging and discharging control of the flywheel energy storage system is proposed.

Get a quote

A Review of Flywheel Energy Storage System Technologies

One energy storage technology now arousing great interest is the flywheel energy storage systems (FESS), since this technology can offer many advantages as an energy storage

Get a quote

Flywheel energy storage

OverviewSee alsoMain componentsPhysical characteristicsApplicationsComparison to electric batteriesFurther readingExternal links

• Energy portal• Beacon Power• Compensated pulsed alternator – Form of power supply• Electric double-layer capacitor – High-capacity electrochemical capacitor

Get a quote

Energy Storage Systems

Y. Liu Virginia Tech, Blacksburg, Virginia, USA Keywords: Energy Storage, power electronics, battery energy storage, superconducting magnetic energy storage, flywheel energy storage,

Get a quote

Technology: Flywheel Energy Storage

Each FESS module has a power electronics module which allows its AC motor-generator to interface with a DC bus that is common to several FESS modules. Power and energy can be

Get a quote

Flywheel energy storage systems: Review and simulation for an

Flywheel energy storage systems (FESSs) store mechanical energy in a rotating flywheel that convert into electrical energy by means of an electrical machine and vice versa

Get a quote

Simulation of Flywheel Energy Storage System Controls

the flywheel energy storage model has been presented. This model incor-porates an electro-mechanical machine model, which is able to simulate energy transfer to and from the flywheel.

Get a quote

6 FAQs about [Is flywheel energy storage AC or DC ]

What is the difference between a flywheel and a battery storage system?

Flywheel Systems are more suited for applications that require rapid energy bursts, such as power grid stabilization, frequency regulation, and backup power for critical infrastructure. Battery Storage is typically a better choice for long-term energy storage, such as for renewable energy systems (solar or wind) or home energy storage.

What is flywheel energy storage system (fess)?

Flywheel Energy Storage System (FESS) is an electromechanical energy storage system which can exchange electrical power with the electric network. It consists of an electrical machine, back-to-back converter, DC link capacitor and a massive disk.

How does Flywheel energy storage work?

Flywheel energy storage (FES) works by accelerating a rotor (flywheel) to a very high speed and maintaining the energy in the system as rotational energy.

Could flywheels be the future of energy storage?

Flywheels, one of the earliest forms of energy storage, could play a significant role in the transformation of the electri-cal power system into one that is fully sustainable yet low cost.

Are flywheels better than batteries?

Lifespan: Flywheels tend to last much longer than batteries, especially for high-cycle applications. Suitability for Short-Term Energy Needs: Flywheels excel in managing short-term energy surges or imbalances, while batteries are often better for long-term storage. Which Is Better: Flywheel or Battery Energy Storage?

Can flywheel technology improve the storage capacity of a power distribution system?

A dynamic model of an FESS was presented using flywheel technology to improve the storage capacity of the active power distribution system . To effectively manage the energy stored in a small-capacity FESS, a monitoring unit and short-term advanced wind speed prediction were used . 3.2. High-Quality Uninterruptible Power Supply

Guess what you want to know

-

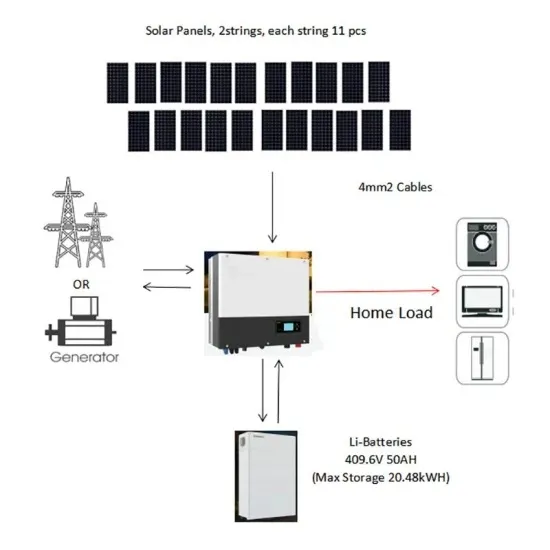

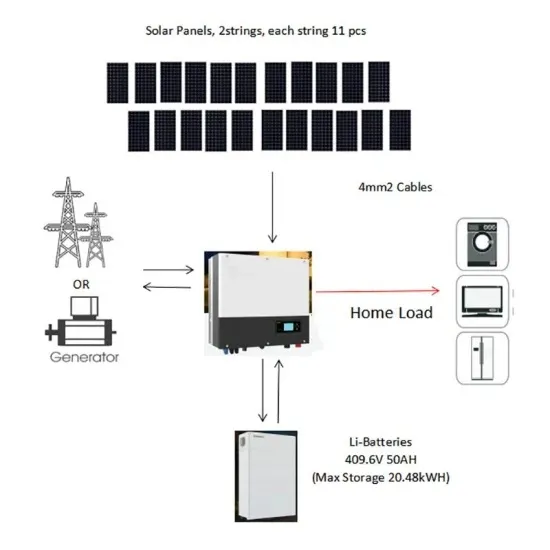

Energy storage power station DC AC

Energy storage power station DC AC

-

Senegal energy storage AC DC power supply manufacturer

Senegal energy storage AC DC power supply manufacturer

-

Is the energy storage battery AC or DC

Is the energy storage battery AC or DC

-

Flywheel energy storage fire protection design

Flywheel energy storage fire protection design

-

What does flywheel energy storage consist of

What does flywheel energy storage consist of

-

Flywheel Energy Storage Power Station Topology

Flywheel Energy Storage Power Station Topology

-

120kw Flywheel Energy Storage

120kw Flywheel Energy Storage

-

Korea flywheel energy storage hybrid power supply

Korea flywheel energy storage hybrid power supply

-

Huawei Colombia Energy Storage Flywheel

Huawei Colombia Energy Storage Flywheel

-

Malawi 100MW flywheel energy storage

Malawi 100MW flywheel energy storage

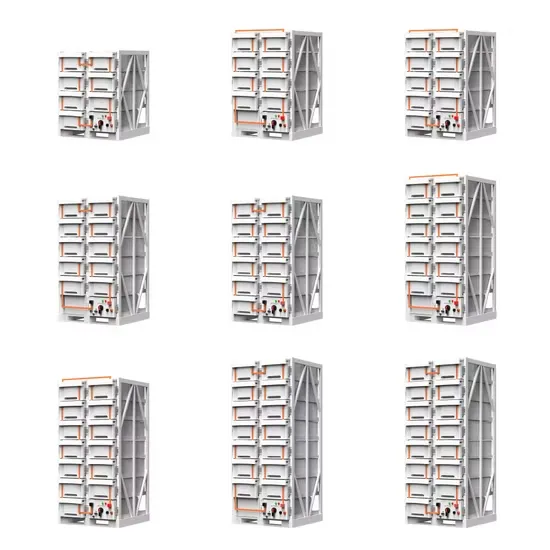

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

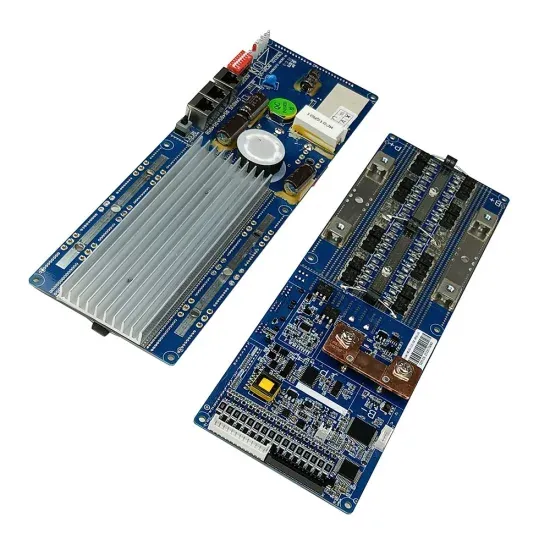

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.