Modeling, Control, and Simulation of a New Topology of Flywheel Energy

First, a new topology of FESS in MGs is introduced, where the FESS is connected at the same DC-bus of the fuel cells and the Photovoltaic (PV) inverter instead of connecting it

Get a quote

New Energy Storage System Links Flywheels And Batteries

1 day ago· The US startup Torus Energy combines flywheel technology with 21st century battery chemistry in one advanced energy storage system

Get a quote

Modeling, Control, and Simulation of a New Topology of Flywheel

The fluctuating nature of many renewable energy sources (RES) introduces new challenges in power systems. Flywheel Energy Storage Systems (FESS) in general have.

Get a quote

World''s Largest Flywheel Energy Storage System

Where these renewable technologies fall short is the inability to store energy without the use of gigantic battery banks. The flywheel system

Get a quote

Flywheel energy storage

Basically, a modern flywheel energy storage system (FESS), consists of five key components; 1) flywheel rotor, 2) bearings, 3) electrical machine, 4) power electronic interface, and 5) housing.

Get a quote

Design of Flywheel Energy Storage System – A Review

This paper extensively explores the crucial role of Flywheel Energy Storage System (FESS) technology, providing a thorough analysis of its components. It extensively

Get a quote

Topology optimization of energy storage flywheel

In order to improve the energy density of energy storage flywheel, topology optimization method exploring the structural layout of the flywheel rotor geometry is presented

Get a quote

Topology optimization of energy storage flywheel

Abstract To increase the energy storage density, one of the critical evaluations of flywheel performance, topology optimi-zation is used to obtain the optimized topology layout of the

Get a quote

Modeling, Control, and Simulation of a New Topology of

The purpose of this paper is twofold. First, a new topology of FESS in MGs is introduced, where the FESS is connected at the same DC-bus of the fuel cells and the Photovoltaic (PV) inverter

Get a quote

Modeling, Control, and Simulation of a New Topology of Flywheel Energy

The fluctuating nature of many renewable energy sources (RES) introduces new challenges in power systems. Flywheel Energy Storage Systems (FESS) in general have.

Get a quote

Design and prototyping of a new flywheel energy

This study presents a new ''cascaded flywheel energy storage system'' topology. The principles of the proposed structure are presented.

Get a quote

Modeling, Control, and Simulation of a New Topology of Flywheel Energy

The fluctuating nature of many renewable energy sources (RES) introduces new challenges in power systems. Flywheel Energy Storage Systems (FESS) in general have a longer life span

Get a quote

Stress constrained topology optimization of energy storage

In this article, a density-based stress-constrained topology optimization approach for energy storage flywheel design is proposed. The specific energy of the rotor is maximized,

Get a quote

An Overview of the R&D of Flywheel Energy Storage

The literature written in Chinese mainly and in English with a small amount is reviewed to obtain the overall status of flywheel energy storage

Get a quote

China flywheel energy storage

Company profile: Among the Top 10 flywheel energy storage companies in China, HHE is an aerospace-to-civilian high-tech enterprise. HHE has developed high-power maglev flywheel

Get a quote

Modeling, Control, and Simulation of a New Topology of

Flywheel Energy Storage Systems (FESS) in general have a longer life span than normal batteries, very fast response time, and they can provide high power for a short period of time.

Get a quote

Flywheel energy and power storage systems

During that time several shapes and designs where implemented, but it took until the early 20th century before flywheel rotor shapes and rotational stress were thoroughly

Get a quote

Topology optimization of energy storage flywheel

In this article, a density-based stress-constrained topology optimization approach for energy storage flywheel design is proposed. The specific energy of the rotor is maximized,

Get a quote

Topology Optimization of a Flywheel Energy Storage Rotor

Abstract—This paper deals with topology optimization of the rotor of a flywheel energy storage system (FESS). For isotropic materials the constant stress disc (CSD) is the best choice to

Get a quote

Flywheel Energy Storage System Topology Diagram: The

Ever wondered how futuristic energy storage systems keep Formula E cars zipping or data centers humming during blackouts? Let''s peel back the layers of the flywheel energy storage

Get a quote

Modeling, Control, and Simulation of a New Topology

First, a new topology of FESS in MGs is introduced, where the FESS is connected at the same DC-bus of the fuel cells and the Photovoltaic

Get a quote

Research Progress of Coordination Control Strategy for Flywheel

This paper firstly discusses the research progress of coordinated control strategies for flywheel array energy storage systems internationally in recent years, and summarizes and

Get a quote

Overview of Control System Topology of Flywheel Energy Storage

The concept of flywheel energy storage is to store the electrical energy in the form of kinetic energy by rotating a flywheel which is connected mechanically between motor and

Get a quote

Design and prototyping of a new flywheel energy storage system

This study presents a new ''cascaded flywheel energy storage system'' topology. The principles of the proposed structure are presented. Electromechanical behaviour of the system

Get a quote

Overview of Control System Topology of Flywheel Energy Storage

scientific article published in 2022Overview of Control System Topology of Flywheel Energy Storage System in Renewable Energy Application for Alternative Power Plant(Q114052616)

Get a quote

Guess what you want to know

-

Global Flywheel Energy Storage Power Station

Global Flywheel Energy Storage Power Station

-

Austria s Flywheel Energy Storage Photovoltaic Power Generation Ranking

Austria s Flywheel Energy Storage Photovoltaic Power Generation Ranking

-

Small photovoltaic power station energy storage

Small photovoltaic power station energy storage

-

Palestinian Power Grid Wind and Solar Energy Storage Power Station

Palestinian Power Grid Wind and Solar Energy Storage Power Station

-

How much does it cost to invest in a Slovenian energy storage power station

How much does it cost to invest in a Slovenian energy storage power station

-

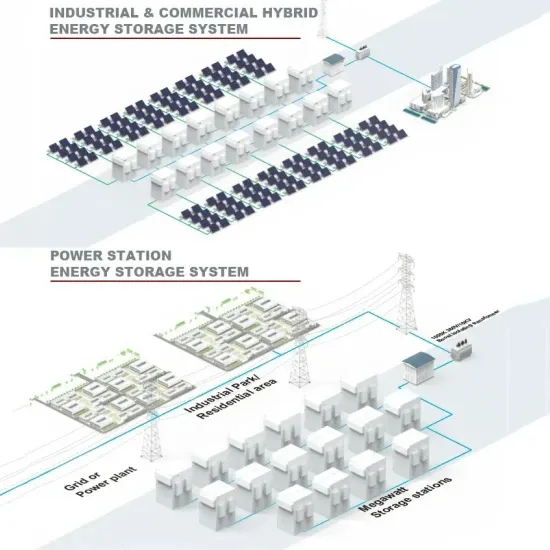

Energy Storage Power Station Project Solution

Energy Storage Power Station Project Solution

-

Equatorial Guinea Energy Storage Container Power Station Quote

Equatorial Guinea Energy Storage Container Power Station Quote

-

Explosion-proof design scheme for energy storage power station

Explosion-proof design scheme for energy storage power station

-

US photovoltaic power station energy storage project

US photovoltaic power station energy storage project

-

What are the energy storage systems of the Grenada power station

What are the energy storage systems of the Grenada power station

Industrial & Commercial Energy Storage Market Growth

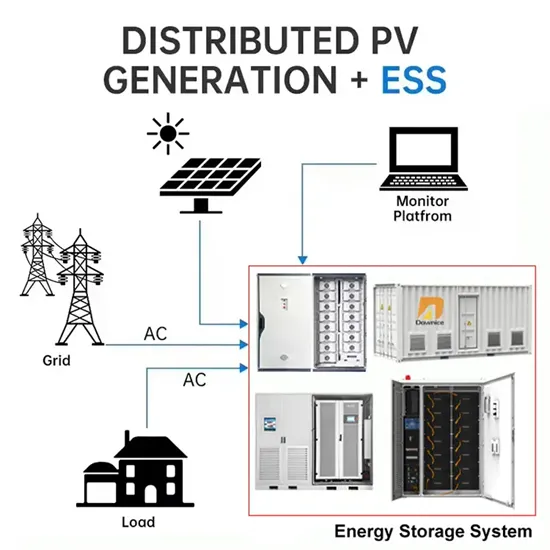

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.