Energy Storage Power Station Fire Prevention and Explosion

How do I design an explosion prevention system for an ESS? The critical challenge in designing an explosion prevention system for a ESS is to quantify the source term that can describe the

Get a quote

design of explosion-proof wall for energy storage device in power plant

This work developed a performance-based methodology to design a mechanical exhaust ventilation system for explosion prevention in Li-Ion-based stationary battery energy storage

Get a quote

CN114534144A

The invention belongs to an electric energy storage system, in particular to a lithium battery energy storage system, and particularly relates to a fireproof and explosion-proof...

Get a quote

Optimization Analysis of Main Power House Design of a Large

Abstract Introduction The compressed air energy storage power station lacks corresponding codes as technical support in the design of main power House. There are some controversial

Get a quote

Energy storage power station explosion prevention and

The safety prevention and control of energy storage power stations run through multiple key links such as battery manufacturing, power station design and construction, power

Get a quote

Explosion-proof standards for battery energy storage cabinets

Why do energy storage containers, industrial and commercial energy storage cabinets, and energy storage fire protection systems need explosion-proof f y oil-damped door closers,

Get a quote

What is the explosion-proof distance of the energy

The notion of explosion-proof distance does not exist in a vacuum; it intertwines with a host of other considerations, including the overall design of

Get a quote

Explosion Control Guidance for Battery Energy Storage

EXECUTIVE SUMMARY grid support, renewable energy integration, and backup power. However, they present significant fire and explosion hazards due to potential thermal runaway

Get a quote

Ex Infrastructure in Malaysia

"Ex" is an internationally recognised abbreviated term for explosion-proof equipment and installation in an explosive atmosphere Standards and Technical Committee

Get a quote

Fire protection design of energy storage station

A building with 100 tons of LIBs in an energy storage power station caught fire, Illinois, USA: Battery spontaneous combustion: Fire protection design of shelf spacing in lithium-ion

Get a quote

Safety Hazards And Rectification Plans For Energy

Discover safety hazards and rectification plans for energy storage power stations. Explore the challenges associated with energy storage safety,

Get a quote

Basic concepts for explosion protection

In such cases protection and safety are provided by equipment which is reliably explosion proof. Such solution, by providing type(s) of protec-tion is referred to as secondary explosion

Get a quote

Study on the influence of the thermal protection

The thermal runaway chain reaction of batteries is an important cause of the battery energy storage system (BESS) accidents, and safety

Get a quote

CFD analysis of performance-based explosion protection design

The results of this analysis show that the second design option (the combustible concentration reduction method) provides the best outcome for explosion protection of the

Get a quote

Explosion Control of Energy Storage Systems

Several competing design objectives for ESS can detrimentally affect fire and explosion safety, including the hot aisle/cold aisle layout for

Get a quote

A Design and Safety Analysis of the "Electricity

The design of an "Electric-Hydrogen-Ammonia" energy storage system proposed in this paper provides a new idea for zero-carbon energy

Get a quote

Clause 10.3 Energy Storage Systems

10.3.2 Temporary Energy Storage System installation on construction sites ESS installation on construction sites shall be located outdoors and comply with all the following requirements:

Get a quote

design of explosion-proof wall for energy storage device in power

This work developed a performance-based methodology to design a mechanical exhaust ventilation system for explosion prevention in Li-Ion-based stationary battery energy storage

Get a quote

POWER PLANT DESIGN MANUAL

Maintenance. Power plant arrangement will permit reasonable access for operation and maintenance of equipment. Careful attention will be given to the arrangement of equipment,

Get a quote

Numerical study on batteries thermal runaway explosion-venting

With the rapid development of electrochemical energy storage, the energy storage system (ESS) container, as a novel storage and production unit for lithium-ion batteries facility,

Get a quote

Energy storage station explosion design unit

First, the double-layer structure prefabricated cabin energy storage is introduced; then, a simplified model of the double-layer prefabricated cabin energy-storage power station is

Get a quote

White Paper on Active Ventilation Explosion-Proof System

Validates safety performance of energy storage containers under real fire conditions by simulating: extreme thermal runaway propagation, explosion risks, and fire suppression

Get a quote

Physical Security: Designing Buildings to Resist

This section addresses the design of the structure of a building to withstand blast loads. The four basic physical protection strategies for buildings to resist

Get a quote

广汽集团研究院

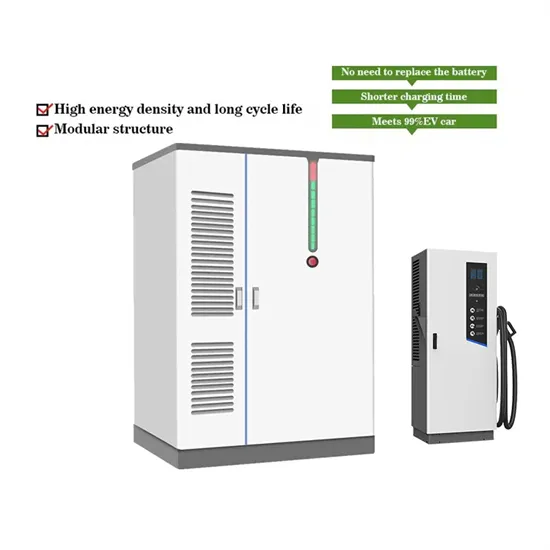

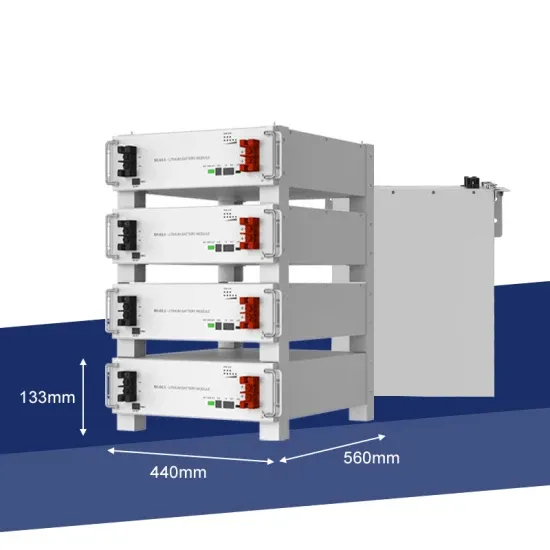

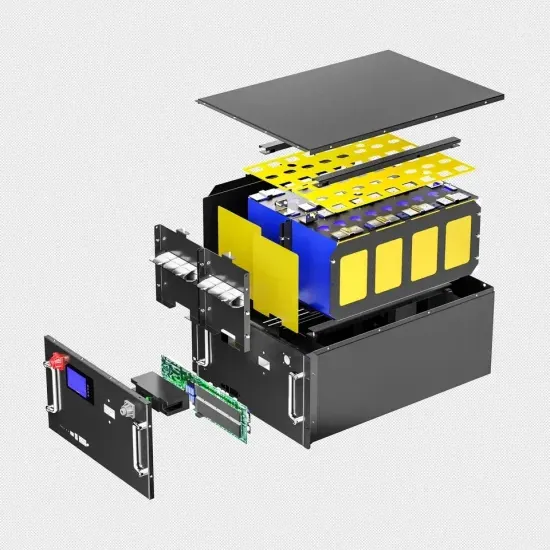

1、Overview This project is a prefabricated cabinet-typed liquid-cooling energy storage battery system——3.25MWh energy storage liquid-cooling battery prefabricated cabinet design

Get a quote

What is the explosion-proof distance of the energy storage power station?

The notion of explosion-proof distance does not exist in a vacuum; it intertwines with a host of other considerations, including the overall design of the energy storage facility,

Get a quote

Explosion Control of Energy Storage Systems

Several competing design objectives for ESS can detrimentally affect fire and explosion safety, including the hot aisle/cold aisle layout for cooling efficiency, protection

Get a quote

6 FAQs about [Explosion-proof design scheme for energy storage power station]

How does ESS design affect fire and explosion safety?

Several competing design objectives for ESS can detrimentally affect fire and explosion safety, including the hot aisle/cold aisle layout for cooling efficiency, protection against water and dust ingress into the enclosure, and the use of larger cells with increased energy density.

Can passive protection be used as a sole explosion protection scheme?

The two main challenges in using passive protection methodology are design constraints for the enclosure and lack of validation data to support calculation methodology. These challenges make it difficult to obtain a feasible design for deflagration venting of ESS enclosures as the sole explosion protection scheme for most configurations.

Should deflagration venting be used as passive explosion protection?

In general, using deflagration venting as passive explosion protection in addition to an active system has multiple benefits due to the nature of the battery failure event, which involves a rapid release of flammable gases.

What are the different types of explosion control options for ESS?

The two types of explosion control options for ESS, NFPA 68 deflagration venting and NFPA 69 exhaust ventilation, are based on a design basis determined from UL 9540A test data. This testing is meant to provide baseline data for the analysis and is generally extrapolated to a sufficiently conservative hazard scenario for the ESS installation.

What are energy storage systems (ESS)?

Energy storage systems (ESS) are being installed in the United States and all over the world at an accelerating rate, and the majority of these installations use lithium-ion-based battery technology.

Why are explosion hazards a concern for ESS batteries?

For grid-scale and residential applications of ESS, explosion hazards are a significant concern due to the propensity of lithium-ion batteries to undergo thermal runaway, which causes a release of flammable gases composed of hydrogen, hydrocarbons (e.g. methane, ethylene, etc.), carbon monoxide, and carbon dioxide.

Guess what you want to know

-

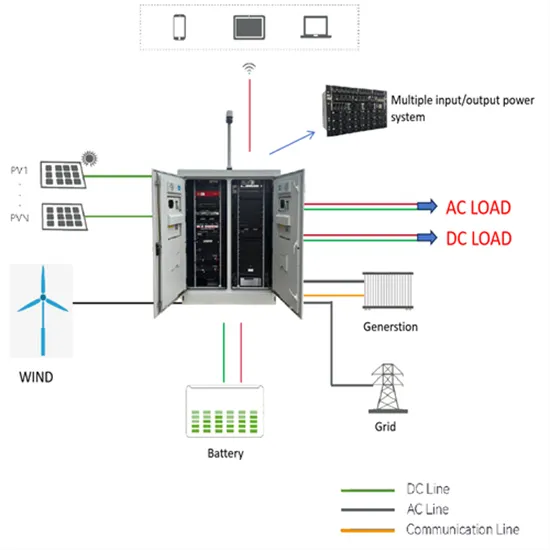

Working principle and complete design scheme of containerized energy storage power station

Working principle and complete design scheme of containerized energy storage power station

-

Tower Energy Storage Power Station Design Scheme

Tower Energy Storage Power Station Design Scheme

-

Design of energy storage power station in Democratic Republic of Congo

Design of energy storage power station in Democratic Republic of Congo

-

Energy Storage Power Station Planning Scheme

Energy Storage Power Station Planning Scheme

-

Moldova Energy Storage Power Station Planning Scheme

Moldova Energy Storage Power Station Planning Scheme

-

North Africa Energy Storage Power Station New Energy Engineering Design

North Africa Energy Storage Power Station New Energy Engineering Design

-

Australian photovoltaic power station energy storage design

Australian photovoltaic power station energy storage design

-

Energy storage power station configuration design

Energy storage power station configuration design

-

Morocco private energy storage power station

Morocco private energy storage power station

-

Energy Storage Power Station Dispatching Management

Energy Storage Power Station Dispatching Management

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.