Understanding Battery Management Systems for

Want to understand battery management systems for portable power stations and solar generators? Here''s everything you need to know — and how they work.

Get a quote

How Do You Properly Wire a Lithium Battery BMS?

To properly wire a lithium battery BMS, first connect the battery pack''s main negative to the B- terminal on the BMS. Then link the balance wires sequentially to each cell''s

Get a quote

Battery Management Systems (BMS): A Complete Guide

A BMS plays a crucial role in ensuring the optimal performance, safety, and longevity of battery packs. This comprehensive guide will cover the fundamentals of BMS, its

Get a quote

Understanding Battery Management Systems (BMS) in Lithium

At its core, a BMS acts as a traffic light for the battery —controlling whether the battery can charge or discharge based on a set of critical parameters. Think of the BMS as a computerized

Get a quote

The Complete Guide To A Battery Management System

Centralized BMS topology, distributed BMS topology and modular BMS topology are three major topology types. The topology of battery management system plays key role in

Get a quote

YamBMS JK-BMS-CAN with new Cut-Off Charging Logic (open

As for integreting Deye BMS in conjunction with JK PB, there is a small issue. Deye BMS implementation doesn''t expose cells voltages - so YamBMS is a bit confused when trying

Get a quote

1S, 2S, 3S, 4S BMS Circuit Diagram for Li-ion Batteries

In this guide, we will dive deep into BMS circuit diagram for 1S, 2S, 3S, and 4S Li-ion battery configurations, providing detailed explanations of its components and functionality.

Get a quote

Best Inverters Compatible With 100Ah Battery for RVs, Solar, and

3 days ago· Choosing the right inverter for a 100Ah battery is critical for maximizing power efficiency in RVs, solar setups, and off-grid systems. This article reviews five top inverters and

Get a quote

How does the BMS know how much current to draw from the

Say you have a 12SXP battery pack. Would any 50.4 V brick work as long as you use the correct connector for the battery? How does the BMS know its connected to a 2.4 A brick vs a 5 A

Get a quote

4. System Design considerations and examples

The example below shows the Lynx Smart BMS in a system with two Lynx Distributors. Together they form a continuous busbar with fused battery connections, battery monitor, BMS system,

Get a quote

Infineon-BMS_Battery_protection_MOSFET_selection-TechA

What is a bidirectional power switch (BDPS), and how to realize it bidirectional switch is an active switch that has the ability to block the current in both directions. It offers effective protection

Get a quote

How to Assemble a Battery Pack with a BMS Module | Step-by

Learn how to safely assemble a battery pack with a BMS module. Our step-by-step guide covers materials needed, safety precautions, detailed assembly instructions, and testing

Get a quote

BMS fisrt connection, cables order question

That battery kit with its thin nickel strips and 20amp BMS is designed for casual use with a 20amp Controller. So why the need for VTC6 cells with a 6P MAX Continuous

Get a quote

Achieve Bidirectional Control and Protection Through Back

ABSTRACT Applications such as high-side battery switching demands a power switch capable of bidirectional current flow, bidirectional voltage blocking for proper power management. This

Get a quote

Battery Management Systems (BMS): A Complete Guide

A BMS plays a crucial role in ensuring the optimal performance, safety, and longevity of battery packs. This comprehensive guide will cover the

Get a quote

Battery Management System Tutorial

There are many types of battery management ICs available. The grouping of the functional blocks varies widely from a simple analog front end that offers balancing and monitoring and requires

Get a quote

How to Connect a BMS to Your Battery Pack

Learn how to connect a BMS to your battery pack with our step-by-step guide. Ensure safety, efficiency, and longevity for your lithium-ion batteries.

Get a quote

Advanced Automotive Battery | LG Energy Solution

Core Competitiveness LG Energy Solution is taking the lead in popularizing electric vehicles that are safe, fast, and environmentally friendly through cells,

Get a quote

How to Assemble a Battery Pack with a BMS Module

Learn how to safely assemble a battery pack with a BMS module. Our step-by-step guide covers materials needed, safety precautions, detailed

Get a quote

Overview of batteries and battery management for electric vehicles

Advances in EV batteries and battery management interrelate with government policies and user experiences closely. This article reviews the evolutions and challenges of (i)

Get a quote

How To Hook up and Install A BMS To Battery

Attaching a BMS to a battery is fairly straightforward. The P- connection goes to the negative side of your discharge connector. If you have a separate port BMS, the C-

Get a quote

Battery Management System

A battery management system (BMS) is defined as an essential component in a battery pack that monitors and controls the battery''s temperature, voltage, and charging/discharging processes,

Get a quote

What is a Battery Management System (BMS)? –

Battery management system (BMS) is technology dedicated to the oversight of a battery pack, which is an assembly of battery cells, electrically organized in a

Get a quote

6 FAQs about [BMS battery direction]

How do you connect a BMS to a battery?

Identify Connections: Locate the main positive (P+) and negative (P-) terminals on the battery. Connect Main Wires: Attach the P- wire from the BMS to the negative terminal of the battery and P+ to the positive terminal. Attach Balance Leads: Connect the balance leads from the BMS to each cell group in series, ensuring correct order.

Do lithium ion batteries need a BMS system?

Lithium-ion batteries, especially custom lithium ion battery packs, need a BMS (Battery Management System) to ensure the battery is reliable and safe. The battery management system is the brain of the lithium battery and reports the status and health of the battery. Let’s get a better understanding from this article. What is a BMS System?

How do I wire a lithium battery BMS?

When wiring a lithium battery BMS, you will need several tools and materials: Soldering Iron: For making secure connections. Heat Shrink Tubing: To insulate connections. Wire Strippers: For preparing wire ends. Multimeter: To check voltage levels during setup. Battery Pack: The lithium cells you are working with.

What is centralized battery management system (BMS)?

The topology of battery management system plays key role in determining how battery packs are monitored, controlled, and maintained. In centralized BMS topology, a single BMS printed circuit board (PCB) contains a control unit that monitors all battery cells using multiple communication channels. This design leads to a larger, less flexible BMS.

How do I install a BMS unit?

Step 1: Gather materials Gather the necessary tools and materials, including the BMS unit, wiring harnesses, connectors, and insulation materials. Step 2: Prepare battery packs Prepare the battery pack by ensuring proper cell arrangement and spacing. Step 3: BMS Wiring (This part will be explained in detail in the next section)

Why do you need a BMS circuit?

By implementing a BMS circuit, you can maximize the performance and longevity of your lithium-ion batteries while minimizing the risk of accidents or malfunctions. You can also make a Battery voltage level indicator for your Li-ion battery pack. 2. Understanding the Key Components of a BMS Circuit

Guess what you want to know

-

Estonia lithium iron phosphate battery bms wholesale

Estonia lithium iron phosphate battery bms wholesale

-

Silicon Carbide BMS Battery Management

Silicon Carbide BMS Battery Management

-

Moldova BMS Battery Management Power System Company

Moldova BMS Battery Management Power System Company

-

Sofia BMS battery management system manufacturer

Sofia BMS battery management system manufacturer

-

Maldives BMS lithium battery project

Maldives BMS lithium battery project

-

Greek lithium battery bms function

Greek lithium battery bms function

-

Congo Kinshasa BMS lithium battery

Congo Kinshasa BMS lithium battery

-

Madagascar professional lithium battery bms merchant

Madagascar professional lithium battery bms merchant

-

West African outdoor battery cabinet bms manufacturer

West African outdoor battery cabinet bms manufacturer

-

Taipei BMS Battery Company

Taipei BMS Battery Company

Industrial & Commercial Energy Storage Market Growth

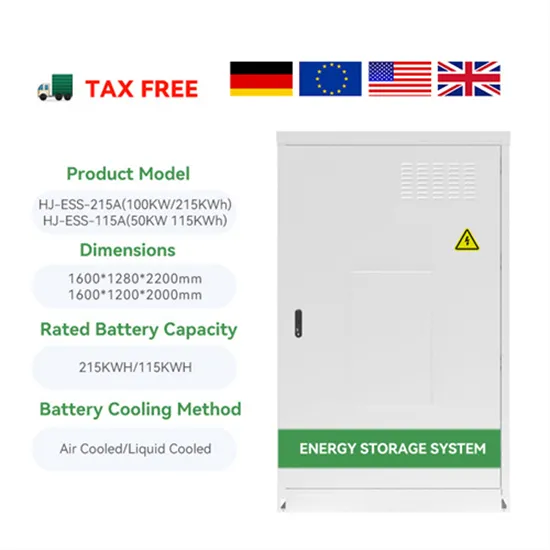

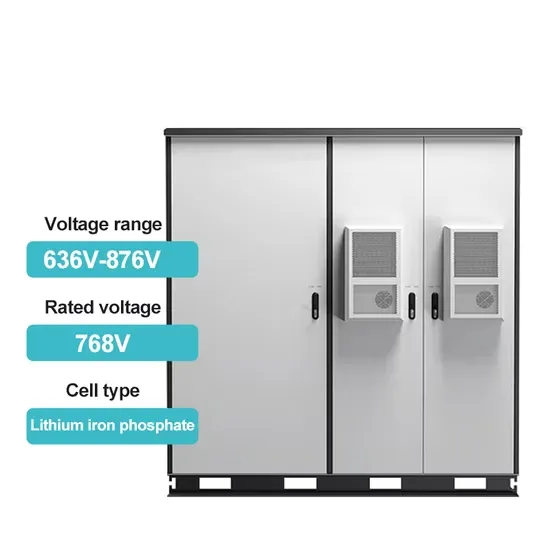

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.