A High Performance High Frequency Inverter Architecture with

In this work, a high frequency inverter system that can work in a wide range of inductive or capacitive load is proposed, which includes Class D inverter, novel

Get a quote

Learn About High vs. Low Frequency Inverters: Which is Right for

High-frequency inverters and low-frequency inverters are two common types of inverters. They have significant differences in their operation and characteristics, and the

Get a quote

Low Frequency/High Frequency Inverters and Inductive Loads

HF inverters have no meaningful surge in most cases. They don''t have the large transformers present in LF units, and can''t do it. Their surge ratings are often for an AC cycle

Get a quote

Understanding inverter frequency – effects and adjustments

The choice between a low-frequency (LF) and high-frequency (HF) inverter depends on various factors, including the application requirements, load characteristics, and budget

Get a quote

Selecting the Proper Inverter / Frequency Converter for your

Therefore, for high-frequency topology inverters (GL and CGL Series), Nova Electric suggests maintaining a ratio of 3:1 between the power output rating of the inverter in VA, and the rating

Get a quote

Low Frequency VS High Frequency Inverter

Discover the differences between low-frequency and high-frequency off-grid inverters, their efficiency, weight, and ideal applications for your solar system.

Get a quote

How many batteries do I need for a 3.5 kVA inverter

What load can a 3.5 kVA inverter carry? The inverter size you have determines the appliances it can carry. The 3.5kva -5kva can carry electric irons but would deplete back power if it is not

Get a quote

A High Frequency Variable Load Inverter Architecture

This thesis presents the design, physical prototype, controller, and experimental results of a high-frequency variable load inverter architecture (referred to as HFVLI) that can directly drive

Get a quote

Learn About High vs. Low Frequency Inverters: Which

High-frequency inverters and low-frequency inverters are two common types of inverters. They have significant differences in their operation

Get a quote

High-Frequency Variable Load Inverter Architecture

The invented high-frequency inverter system enables HF power delivery directly into highly variable impedance loads with a relatively high efficiency. A pair of inverters are coupled and

Get a quote

TPEL2691668

In terms of mechanical construction, the number of inputs and outputs can dictate the design complexity. Also, on the elec-trical point of view, the average and rms current amplitude as

Get a quote

Surge vs. Efficiency: Choosing Between Low and High-Frequency Inverters

The debate between line-frequency and high-frequency inverters is not about which is "better," but which is "right" for a specific task. The line-frequency inverter is a powerful,

Get a quote

How Long Will a 1000W Inverter Run on a 100Ah

A 1000W inverter connected to a 100Ah battery can typically run for about 0.96 hours (or approximately 58 minutes) under full load, assuming an

Get a quote

Selective Dual Duty Cycle Controlled High Frequency Inverter

Dual duty cycle control scheme is used to provide a wide range of high frequency AC output power regulation that is important in many high frequency inverter applications. It found that a

Get a quote

A High Frequency Inverter for Variable Load Operation

Inverters operating at high frequency (HF, 3-30MHz) are important to numerous industrial and commercial applications such as induction heating, plasma generation, and wireless power

Get a quote

Comparing Carrier-Based PWM Techniques in High

This article explores the potential of carrier-based pulse width modulation techniques such as sawtooth, triangular, and sinusoidal, and

Get a quote

Power Frequency Inverter vs High-Frequency Inverter

On the other hand, high-frequency inverters can provide the same power at high frequency with a much smaller and lighter transformer. As a result, the high-frequency inverter

Get a quote

Surge vs. Efficiency: Choosing Between Low and High

The debate between line-frequency and high-frequency inverters is not about which is "better," but which is "right" for a specific task. The line-frequency inverter is a powerful,

Get a quote

A High Performance High Frequency Inverter Architecture with Wide Load

In this work, a high frequency inverter system that can work in a wide range of inductive or capacitive load is proposed, which includes Class D inverter, novel

Get a quote

Harmonic Overload: Impacts Of High-Frequency

During the CIGRE Grid of the Future symposium and workshop, harmonics were recognized as a critical focus in modern electrical systems, where high

Get a quote

Inversion Methods Explained: High Frequency vs Low Frequency

They are typically less expensive, have smaller footprints, and have a lower tolerance for industrial loads. HF inverters have over twice the number of components and use multiple,

Get a quote

A new architecture for high-frequency variable-load inverters

Mentioning: 5 - Abstract-Efficient generation and delivery of high-frequency (HF, 3-30 MHz) power into variable load impedances is difficult, resulting in HF inverter (or power amplifier) systems

Get a quote

IBC12-3KW Pure Sine Wave Inverter (High Frequency) User

1.1 Product overview IBC series pure sine wave high frequency inverter, the product integrates pure sine wave inverter, mains bypass load. Adopts full digital intelligent control Technology,

Get a quote

Surge vs. Efficiency: Choosing Between Low and High-Frequency Inverters

Deconstructing High-Frequency Inverters High-frequency inverters represent a more modern approach, engineered to overcome the size and weight limitations of their line

Get a quote

6 FAQs about [How much load can a high-frequency inverter carry ]

What is a high frequency variable load inverter architecture?

This thesis presents a high frequency variable load inverter architecture along with a physical prototype and e ciency optimizing controller. The inverter architecture consists of two constituent inverters, one connected directly through the load and the other connected through an immittance converter, which acts as a lossless power combiner.

What is a high frequency inverter?

Applications: These inverters are more suitable for off-grid systems where heavy loads and extreme conditions are expected, such as in industrial applications or in remote locations with harsh environments. Weight: High-frequency inverters are lighter than low-frequency inverters, using smaller, lighter transformers.

Can a high frequency inverter be used for a motor / compressor load?

Motor / Compressor Load: Nova Electric does not recommend the use of high frequency inverters (GL or CGL) for motor or compressor loads in general, though they can be modified for such use in certain applications where weight savings are critical (consult factory for details).

Does victron use a high frequency inverter?

Victron combines both inverters, which they call Hybrid HF or Combined high frequency and line frequency technologies. What frequency inverter does growatt use? Growatt uses a high-frequency inverter. Which one is best? Low or high frequency? The best inverter is the low-frequency inverter.

What determines a high or low frequency inverter?

Size and tolerances of the transistors used in the inversion process, and the speed at which they operate determines the classification of high or low frequency. The large majority of inverters available in the retail market are high frequency.

Can a high-frequency variable load inverter directly drive widely variable loads?

Typically a tunable matching network is used to transform the varying load into a ciency and impairing transient response. This thesis presents the design, physical prototype, controller, and experimental results of a high-frequency variable load inverter architecture (referred to as HFVLI) that can directly drive widely variable loads.

Guess what you want to know

-

How big is a high-frequency inverter

How big is a high-frequency inverter

-

How many kilowatts does a 60v inverter carry

How many kilowatts does a 60v inverter carry

-

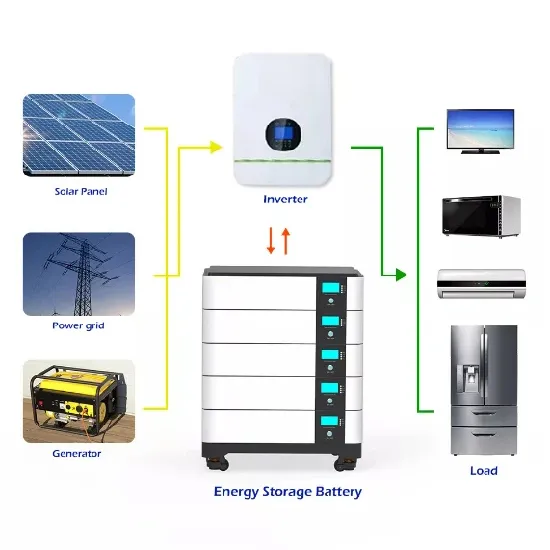

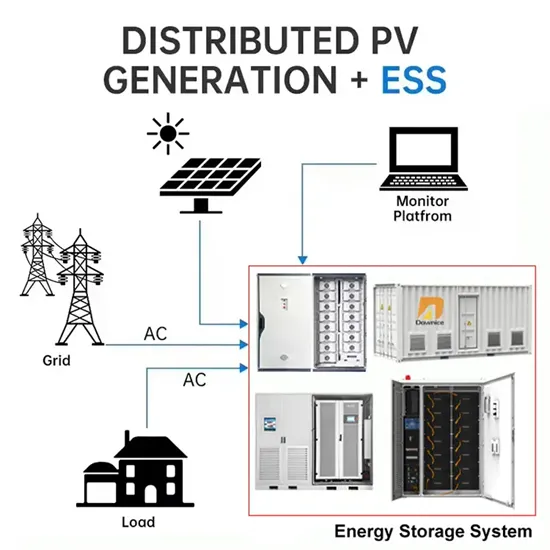

How to connect the mobile energy storage site inverter to the grid

How to connect the mobile energy storage site inverter to the grid

-

How big can a 48V AC inverter be

How big can a 48V AC inverter be

-

How big of an inverter should I use for a 24 volt

How big of an inverter should I use for a 24 volt

-

How many volts can the inverter convert to 220

How many volts can the inverter convert to 220

-

How big an inverter do I need to convert 7200v to 220v

How big an inverter do I need to convert 7200v to 220v

-

How to connect DC inverter to the grid

How to connect DC inverter to the grid

-

How to measure high-frequency batteries for wind power in communication base stations

How to measure high-frequency batteries for wind power in communication base stations

-

How big an inverter can I use with a 12v 50AH lithium battery

How big an inverter can I use with a 12v 50AH lithium battery

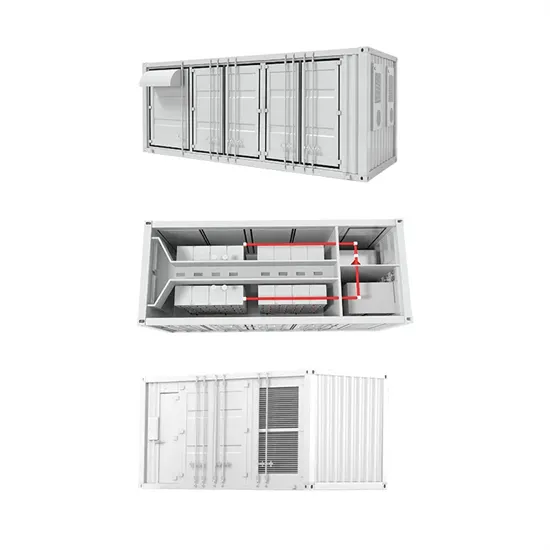

Industrial & Commercial Energy Storage Market Growth

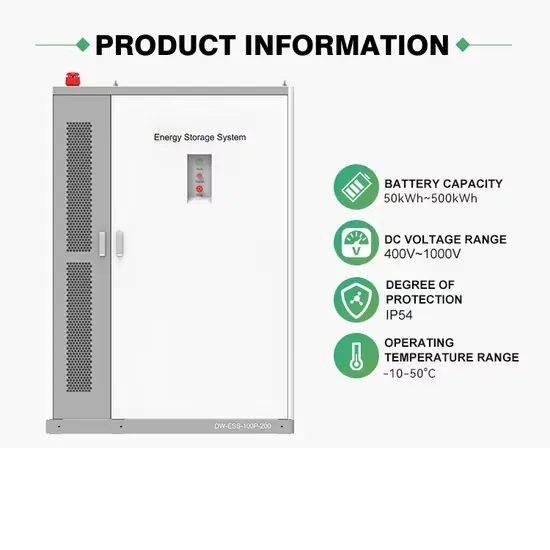

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.