battery cabinet,battery storage cabinet,battery bank

EverExceed designs customized battery cabinets / racks for individual batteries. The cabinet or racking system can be specified to accomodate any battery

Get a quote

Current sampling and measurement in PWM operated AC drives

Current regulation is an essential part of many AC drives and power converters, with fast and accurate measurement of the current being essential for this purpose. High frequency

Get a quote

Simplify Voltage and Current Measurement in Battery Test

Amplifier Usage in Battery Test Equipment In typical systems, a Buck converter is used as the power source for battery charging and a Boost converter is used for battery discharge. Both

Get a quote

Battery Cabinet Monitoring Solutions: The Guardian of Energy

Imagine battery cabinet monitoring solutions that predict cell swelling 72 hours in advance using spiking neural networks. Our prototype achieved 92% prediction accuracy by analyzing

Get a quote

Simplify Voltage and Current Measurement in Battery Test

Voltage and current sensing are the two most significant measurements in battery test equipment systems. Furthermore, the most important parametric characteristics for this application is a

Get a quote

Fault/Failure trouble-shooting instruction and

Warning: Removal of cabinet panels may result in serious injury or even death. Cabinet panels should only be removed by qualified personnel. When working with controller

Get a quote

A High Precision Current Sampling Circuit with Rail-to-Rail

Current information in the lithium-ion battery charging system is important for system control and can be used for overload protection, constant current control

Get a quote

Practical On-Board Measurement of Lithium Ion Battery

In order to provide impedance for a battery management system (BMS), a practical on-board impedance measuring method based on distributed signal sampling is proposed and

Get a quote

Predicting battery impedance spectra from 10-second

Onboard measuring the electrochemical impedance spectroscopy (EIS) for lithium-ion batteries is a long-standing issue that limits the

Get a quote

Battery cabinet sampling system failure

Possible causes are incorrect calibration of current sampling, mismatch between current sensor type and host program, and battery not being charged and discharged deeply for a long time.

Get a quote

Fire Protection for Lithium-ion Battery Energy Storage

As overall demand for energy increases in our modern world – so does the use of renewable sources like wind and solar. As the use of these variable sources of energy grows – so does

Get a quote

Lithium-ion Battery aging machine, 6 V

Model No:-Semco SI BCDS 100V 30A 2CH= Battery Charge & Discharge Cabinet Tester Equipment features The constant voltage and constant current

Get a quote

Battery cabinet current sampling

The battery test systems CT3002N and CT3002D provide solutions for battery module/battery pack tests with higher current/voltage. They can also be used in situations where batteries are

Get a quote

How to Design a Simple and Highly Integrated Battery

In this process, the current and voltage of the battery must be controlled accurately. It is usually required that the precision can reach 0.1%. Therefore, battery formation and test systems

Get a quote

Battery voltage and current sampling chip

Large current sensing in a high-voltage (HV) battery module or string is hard to be realised on-chip. Thus, it is a disadvantage for the system to be miniaturised. A current sensor with a HV

Get a quote

Acrel Hall Current Sensor in Battery Cabinet Monitoring

When the battery is charged and discharged, there are strict requirements on the charge and discharge current. This paper introduces the realization of the battery charge and

Get a quote

Acrel Hall Current Sensor in Battery Cabinet Monitoring

When the battery is charged and discharged, there are strict requirements on the charge and discharge current. This paper introduces the

Get a quote

How to Design a Simple and Highly Integrated Battery

There are two modes of battery charging and discharging: constant current mode and constant voltage mode. In a typical battery charging system, the batteries are charged or discharged at

Get a quote

Microsoft Word

The battery cabinet is equipped with narrow pallet jack or forklift access openings in the front and rear of the cabinet. Move the equipment into the desired location and set in place.

Get a quote

Battery voltage and current sampling chip

However, the sampling delay between the voltage and current of a battery is generally overlooked, which is unavoidable in a modular battery management system (BMS) and would

Get a quote

SERIES BTS

Boost up: Sets step to the battery channel, the channel will work immediately according to the work-step after starting. The step includinge constant current charge, constant voltage

Get a quote

6 FAQs about [Battery cabinet current sampling]

How a rechargeable battery is used in testing systems?

The use of rechargeable batteries in testing systems is becoming increasingly extensive. In order to initialize the rechargeable batteries, the multiple charging and discharging cycles are demanded. In this process, the current and voltage of the battery must be controlled accurately. It is usually required that the precision can reach 0.1%.

How accurate is battery current gauging?

With careful design, you can measure battery current to within 0.2 percent of full scale. With that information, the most accurate gauging systems, taking battery age, temperature, self-discharge, and discharge-charge cycle history into account, can usually estimate remaining battery life to within 1 percent.

How accurate is battery current measurement?

If you're able to accurately sense the current draw, and the battery is well-characterized, you'll be able to accurately determine the amount of time remaining before your mission-critical system dies. With careful design, you can measure battery current to within 0.2 percent of full scale.

How to test a battery before it comes out?

The battery must be tested strictly before it comes out of the factory, and the battery test equipment is used to verify battery pack functionality and performance. For the most commonly used battery testing system in the market is the separation solution, which is a mature solution.

Which battery testing solution is best?

For the most commonly used battery testing system in the market is the separation solution, which is a mature solution. This application report introduces an integration battery testing solution which is simpler than the separation solution in the design.

What is battery test equipment?

Battery test equipment is used to verify battery pack functionality and performance prior to shipment to the customer. This application brief outlines three major functional tests that a battery tester performs while showing how to achieve the desired level of regulated error. ADC Figure 1. Traditional Battery Test Equipment Block Diagram

Guess what you want to know

-

Does the current of the energy storage cabinet battery decrease as it is used

Does the current of the energy storage cabinet battery decrease as it is used

-

How much current does a 5 kWh battery cabinet have

How much current does a 5 kWh battery cabinet have

-

How to derive the current of the energy storage cabinet battery

How to derive the current of the energy storage cabinet battery

-

Battery cabinet voltage and current

Battery cabinet voltage and current

-

Battery cabinet calibration current

Battery cabinet calibration current

-

Rwanda lithium battery site cabinet charging current

Rwanda lithium battery site cabinet charging current

-

What is the normal current of the battery in the energy storage cabinet

What is the normal current of the battery in the energy storage cabinet

-

Current foreign battery cabinet cooling technology

Current foreign battery cabinet cooling technology

-

Is there current in the battery cabinet during discharge

Is there current in the battery cabinet during discharge

-

How to measure the output current and voltage of the battery cabinet

How to measure the output current and voltage of the battery cabinet

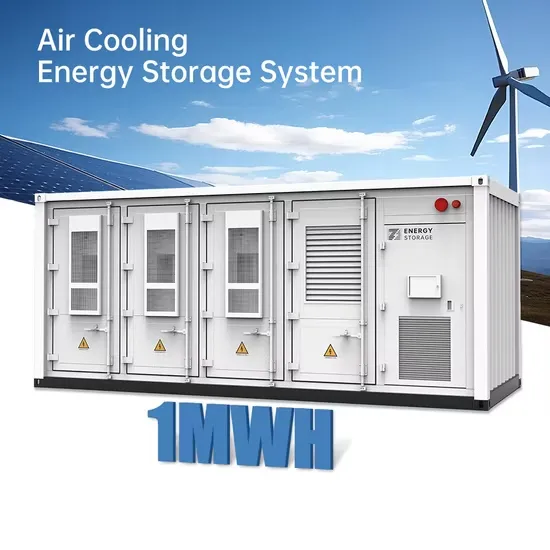

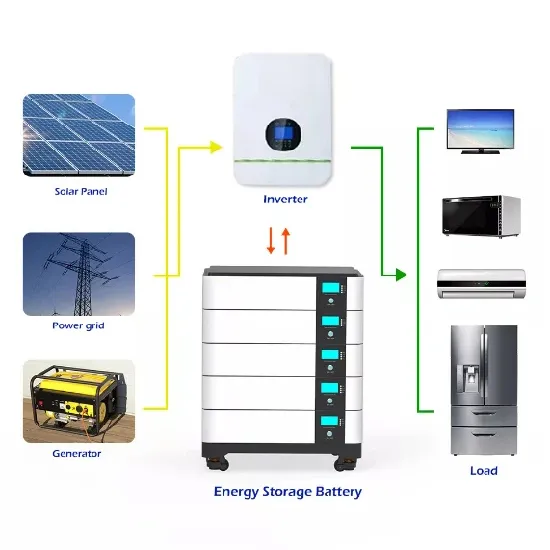

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.