High-frequency full-bridge LLC resonant inverter with GaN HEMT

In this paper, the development of a compact LLC resonant converter based on GaN devices and with output power up to 10 kW is described. The capability of 1 MHz.

Get a quote

High Frequency Vs. Low Frequency Inverters... Which is better?

High Frequency Vs. Low Frequency? Which Inverter is better?00:00 - intro00:43 - low frequency inverters02:15 - High Frequency Inverters03:17 - Comparison

Get a quote

A Very High Frequency dc-dc Converter Based on a Class

The converter power stage comprises a resonant inverter, a transformation stage, and a resonant rectifier. The resonant inverter accepts a dc input voltage, and generates very high frequency

Get a quote

A high efficiency multi-module parallel RF inverter system for

Hydrogen energy plays an important role in achieving carbon neutralization, and plasma induced hydrogen is an effective production method. One challenge is how to

Get a quote

800VA Pure Sine Wave Inverter''s Reference Design

The first step is the conversion of the low voltage DC power to a high voltage DC source, and the second step is the conversion of the high DC source to an AC waveform using pulse width

Get a quote

High-Frequency Inverter: How They Work and Why They Matter

A high-frequency inverter is an electrical device that converts direct current (DC) into alternating current (AC) at a high switching frequency, typically above 20 kHz (Kilohertz), to achieve

Get a quote

Voltage Fed Full Bridge DC-DC & DC-AC Converter High

This application report documents the concept reference design for the DC-DC Stage and the DC-AC Converter section that can be used in the High-Frequency Inverter using TMS320F28069,

Get a quote

High frequency voltage-fed inverter with phase-shift

A voltage-fed resonant LCL inverter with phase-shift control is presented. The control strategy is seen to offer advantages in the megahertz

Get a quote

Analysis on 1 MHz high frequency resonant inverter parallel

Ultra high frequency induction heating voltage resonant inverter parallel operation with 1MHz level based on LLC load was researched in this paper. It explored.

Get a quote

Design of High frequency 1MHZ, 10-20 watt, PWM based inverter

i have to design a MOSFET, PWM based inverter circuit at 1Mhz frequency, a rectifier circuit and transmitting and receiving coils. i want to simulate my results before making

Get a quote

Analysis and Design of a 1MHz LLC Resonant Converter

In this paper, a 1MHz LLC resonant converter is proposed for high efficiency and high power den-sity application. The operational principle of the proposed converter is analysed, and

Get a quote

Development of a current source resonant inverter for high

The operation of the high-frequency CSRI is simulated in SPICE and is shown in Figure 4, where the high Q-factor and switching frequency results in a dramatic change in the input tank

Get a quote

Development of a current source resonant inverter for

High frequency industrial induction heating processes typically employ resonant inverters to reach high efficiency at high power levels.

Get a quote

A High-Frequency Resonant Inverter Topology with Low

ESONANT inverters suitable for high frequency oper-Ration have numerous applications, including as radio-frequency power amplifiers [3]–[5], induction heating and plasma generation

Get a quote

10147042023163256EPE_2023_Final_Full_Paper_VF

The design procedure using analytical equations is detailed. A high frequency model of the converter including PCB parasitic is achieved and simulation results are confronted to

Get a quote

Class E resonant inverter optimized design for high frequency

The Class-E resonant converter can achieve zero-voltage switching and zero-dv/dt switching when the switch is turned on in optimum mode. This paper presents a design

Get a quote

Three-phase three-level GaN-ANPC inverter with a 1 MHz switching frequency

Request PDF | On Nov 7, 2021, Heikki Jarvisalo and others published Three-phase three-level GaN-ANPC inverter with a 1 MHz switching frequency | Find, read and cite all the research

Get a quote

High-Frequency Inverter: How They Work and Why

A high-frequency inverter is an electrical device that converts direct current (DC) into alternating current (AC) at a high switching frequency, typically above 20

Get a quote

Frequency Selection in Switching Power Supply

This article builds on switching frequency concepts to analyze switching power supply designs for three different frequency ranges, sorted from low to high.

Get a quote

Versatile High-Frequency Inverter Module for Large-Signal

This paper presents the challenges encountered and the solutions adopted during the construction of a versatile voltage-fed high-frequency series-resonant half-bridge inverter

Get a quote

1 Hz to 1 MHz Frequency Reference Generator Circuit

This circuit is an universal frequency generator which you can use in numerous frequency and time period testing applications. It is primarily well

Get a quote

High Frequency Inverter Board Assembly | Best Technology

What is high frequency inverter board? This guide covers its basics, how it works, function and application and differences from low-frequency ones.

Get a quote

Crystal oscillator with inverter gate, crystal engraved with "1 MHz

A crystal has a series resonant point (low impedance) and a parallel impedance point (high impedance) and, with a single inverter, it oscillates closer to the series resonant point.

Get a quote

High-Frequency Three-Phase Interleaved LLC Resonant Converter With

In this paper, a high-frequency gallium nitride (GaN)-based three-phase LLC converter is employed to address these aforementioned challenges. With GaN operating at 1

Get a quote

6 FAQs about [1MHz high frequency inverter]

What is a high frequency inverter?

In many applications, it is important for an inverter to be lightweight and of a relatively small size. This can be achieved by using a High-Frequency Inverter that involves an isolated DC-DC stage (Voltage Fed Push-Pull/Full Bridge) and the DC-AC section, which provides the AC output.

Which power supply topologies are suitable for a high frequency inverter?

The power supply topologies suitable for the High-Frequency Inverter includes push-pull, half-bridge and the full-bridge converter as the core operation occurs in both the quadrants, thereby, increasing the power handling capability to twice of that of the converters operating in single quadrant (forward and flyback converter).

What is a 100W 1MHz resonant converter for high power density led driver?

This paper presents the design of a 100W 1MHz single-switch GaN-based resonant converter for high power density LED driver. The proposed prototype is based on the class E topology and performs Zero Voltage Switching (ZVS) as well as inherent Power Factor Correction (PFC) capability. The design procedure using analytical equations is detailed.

What is 1 MHz power switch?

The capability of 1 MHz operation contributes to small overall dimensions involving the power stage, drivers and also the control system. The characteristics of the power switches, consisting of three GaN transistors in parallel placed on an insulated metal substrate (IMS), are provided together with their double pulse test performance.

Can a 100W 1MHz GaN-based Class E/D DC/DC converter improve power density?

Conclusion This paper proposed a complete design procedure for a 100W 1MHz GaN-based class E/D DC/DC converter with the objective of replacing the conventional two-stage topology of LED drivers for improved power density.

Can a resonant DC/DC converter perform ZVS and PFC functionality inherently?

This paper proposed a complete design procedure for a 100W 1MHz GaN-based class E/D DC/DC converter with the objective of replacing the conventional two-stage topology of LED drivers for improved power density. It has been demonstrated that the designed resonant converter is able to perform ZVS and PFC functionality inherently.

Guess what you want to know

-

Yemen Huijue high frequency inverter manufacturer

Yemen Huijue high frequency inverter manufacturer

-

High frequency inverter produces 1200v

High frequency inverter produces 1200v

-

India high frequency inverter

India high frequency inverter

-

Characteristics of high frequency inverter

Characteristics of high frequency inverter

-

The inverter output high voltage frequency is too low

The inverter output high voltage frequency is too low

-

High frequency inverter price in Pakistan

High frequency inverter price in Pakistan

-

Malaysia high frequency inverter price

Malaysia high frequency inverter price

-

Cambodia high frequency power inverter

Cambodia high frequency power inverter

-

High frequency pure sine wave inverter 12V to 48V

High frequency pure sine wave inverter 12V to 48V

-

Georgia High Frequency Inverter Device Factory

Georgia High Frequency Inverter Device Factory

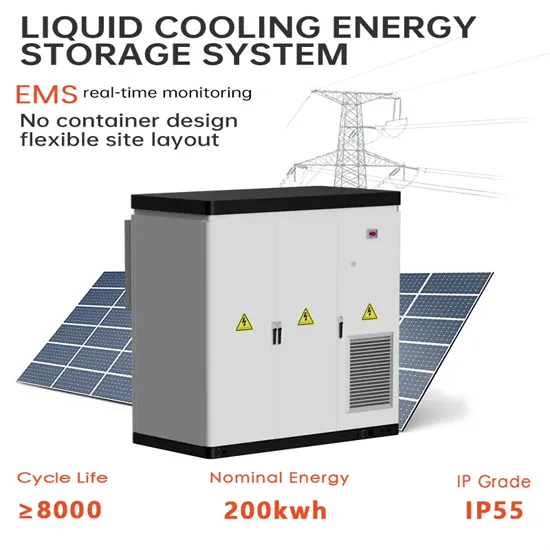

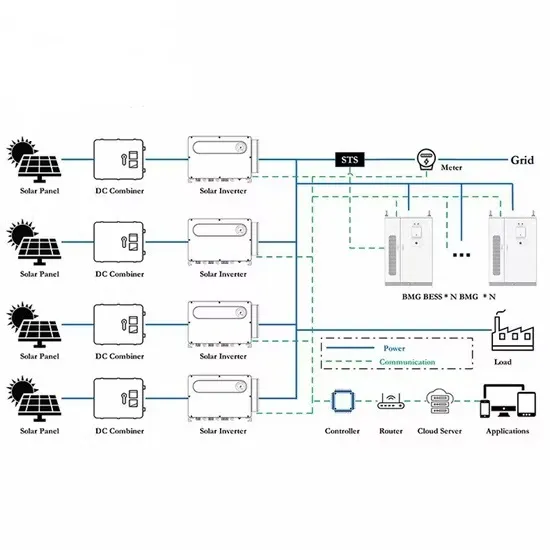

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.