The ship''s electrical network, engine control and automation

The first step is to define the ship type. It goes without saying that the vessel''s size and purpose are key factors when dimensioning the ship''s electrical network. The following illustrate the

Get a quote

Can Container Ships Be Powered By Renewable Energy

Regulatory changes are anticipated by 2030, requiring larger container ships to adopt shore power, while alternatives like wind, batteries, and hydrogen for ship propulsion are

Get a quote

Will future container ships sail on electricity?

Large ships have both a main engine that drives the ship forward and an auxiliary engine that, using fuel, generates power for the actual ship operation—such as lighting and

Get a quote

Energy extraction potential from wave-induced ship motions

The concept of extracting energy from wave-induced ship motions is interesting since it could serve as a potential means for reducing the use of conventional fuels on ships

Get a quote

Comparative feasibility study of combined cycles for marine power

This study investigates the combined power cycles for the electric propulsion system in a large container ship. Combined cycles have the primary power machinery and a

Get a quote

Business case for a Feedermax containership with a shore power

This case study evaluates a mobile shore power battery barge designed for a 1,730 TEU containership in the Port of Rotterdam. An average power demand of 329 kW and

Get a quote

What is the average shore power demand of a container ship

The IMO estimates shore power demand for containerships based on TEU (Twenty-foot Equivalent Unit) sizes, with results ranging from 0 kW for the smallest ships to a

Get a quote

Prediction of the very

Cargo capacity expressed in 20-foot equivalent units (TEU) was identified as the main predictor of the electricity generation capacity based on a representative very- and ultra-large container

Get a quote

(PDF) Prediction of the very-and ultra-large Container Ships

Contemporary configurations of ships'' electric power stations are presented and discussed. Cargo capacity expressed in 20-foot equivalent units (TEU) was identified as the main predictor of the...

Get a quote

ELI5: Why is it more efficient for large ships to be powered

The most common propulsion for the largest cargo ships is still a slow-speed reversible diesel engine directly coupled to the propeller shaft. It''s simply the most efficient means of doing what

Get a quote

Ship Engines – 7 Monster Engine Designs, Part 1

Ship owners like a single engine/single propeller design and the new generation of larger container ships needed a bigger engine to propel

Get a quote

main engine output on certain type of merchant ships (e.g.

main engine output on certain type of merchant ships (e.g. container ships with a large number of refrigerated containers), minimalization of electricity produ-ction costs has gained in the last

Get a quote

Assessment of Ship Electric Power Consumption

Refrigerated containers are a large part of the energy consumption on board of a container ship since the cargo must be refrigerated 24 hours a day during all navigation time, in order to

Get a quote

China reveals molten-salt nuclear reactor-driven

It is also a completely zero-emissions fuel. "The ultra-large nuclear container ship is designed to truly achieve zero emissions during the ship''s

Get a quote

Can Container Ships Be Powered By Renewable Energy

Researchers are developing a fuel cell system that will generate CO2-free power for large ships, such as container ships. The Laura Maersk, the world''s first container vessel

Get a quote

Business case for a Feedermax containership with a

This case study evaluates a mobile shore power battery barge designed for a 1,730 TEU containership in the Port of Rotterdam. An average

Get a quote

Will future container ships sail on electricity?

Large ships have both a main engine that drives the ship forward and an auxiliary engine that, using fuel, generates power for the actual ship

Get a quote

Nuclear propulsion in ocean merchant shipping: The role of

Global marine shipping annually accounts for about one billion tonnes of CO 2 equivalent greenhouse gas emissions. Nuclear power propulsion may be an option to de

Get a quote

Research progress on ship power systems integrated with new

Solar energy can now be used as the main power source to propel small-scale ships, and as an auxiliary power source in large-scale ships to supply lighting, communication

Get a quote

Energy extraction potential from wave-induced ship motions

In the present study, we extend the assessment to cover cargo and large-sized ships, and we generalise the findings to consider all wave-encounter angles (from head waves

Get a quote

The evolution of container ships and their sizes

The race for the largest container ship The Triple E vessels, the first Very Large Container Vessels, remained the largest vessels until 2013 when multiple

Get a quote

Research progress on ship power systems integrated with new energy

Solar energy can now be used as the main power source to propel small-scale ships, and as an auxiliary power source in large-scale ships to supply lighting, communication

Get a quote

ELI5: Why is it more efficient for large ships to be powered

The most common propulsion for the largest cargo ships is still a slow-speed reversible diesel engine directly coupled to the propeller shaft. It''s simply the most efficient

Get a quote

Regression analysis for container ships in the early design stage

The seaway trade market has expanded in the last years and container ship dimensions are constantly increasing for higher cargo capacity. In the early design stage, main

Get a quote

Maritime / China Unveils Plans For ''Largest Ever''

China has unveiled plans for a nuclear-powered container ship expected to be the largest ever built, powered by a thorium reactor and

Get a quote

The Case for Nuclear Cargo Ships

A large container ship needs about 3,000 megawatt-hours a day, which is roughly the capacity of the biggest grid battery ever built. "The battery solution is dead before it starts,"

Get a quote

6 FAQs about [Power generation from large container ships]

Can a large container ship have electric propulsion?

Particularly, a large container ship with electric propulsion will be the key element of global trades for sustainable shipping. This study investigates the combined power cycles for the electric propulsion system in a large container ship. Combined cycles have the primary power machinery and a secondary one.

How much power does a container ship need?

For this particular case study it is assumed one auxiliary engine operates at 30% load, resulting in an average power demand of 329 kW and energy demand of 8,482 kWh per day. For the container ship setup, it is assumed that the shore power infrastructure is notavailable.

How many configurations of electric propulsion system are suggested in a large container ship?

Three configurations for the electric propulsion system are suggested in a large container ship. Comparative results of three configurations are provided for selecting an appropriate alternative. A hythane-fueled marine power plant becomes solely available with a stricter EEDI phase.

How much power does a sustainable ship need?

Sustainable Ships’ analysis uses a database of over 3,000 vessels and calculates demand based on auxiliary engine ratings at 30% load. The results vary from 60 kW to 3,825 kW, with an average demand of 584 kW. Only four data point account for the highest outlying values, all except these are below 2,000 kW.

Does a container ship have a propulsion engine?

Large container and other heavy haul ships actually have 1 or more propulsion engines that drive the propeller. They are low speed engines and can run in reverse to turn the propeller backwards. They may have a small reduction gearbox but not much of one.

Can grid-connected PV generation systems be integrated with a ship's electrical propulsion system?

On this basis, increases in the installed capacity of PV generation systems in large-scale ships might enable grid-connected PV generation system to be integrated with a ship's electrical propulsion system, offering significant possibilities for ship design in the future.

Guess what you want to know

-

Sri Lanka energy storage power generation container

Sri Lanka energy storage power generation container

-

Container Power Generation in Nigeria

Container Power Generation in Nigeria

-

Island power generation container price

Island power generation container price

-

Solar rooftop power generation large photovoltaic panels

Solar rooftop power generation large photovoltaic panels

-

Container power generation market trends

Container power generation market trends

-

Laos power generation container

Laos power generation container

-

Oman container power generation

Oman container power generation

-

Refrigerated container with power generation

Refrigerated container with power generation

-

Niue power generation container sales

Niue power generation container sales

-

Container Power Generation Seller Ranking

Container Power Generation Seller Ranking

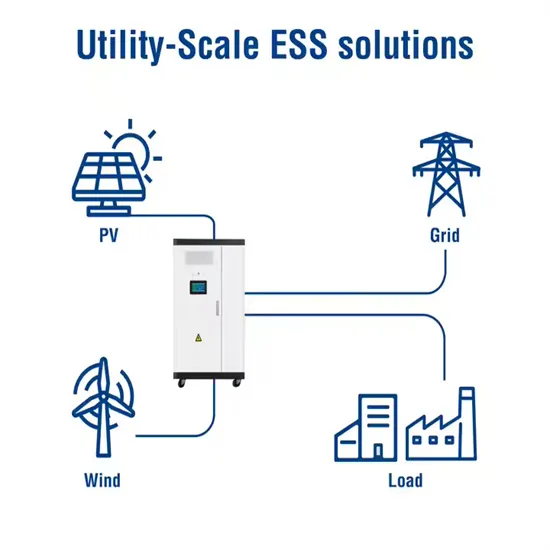

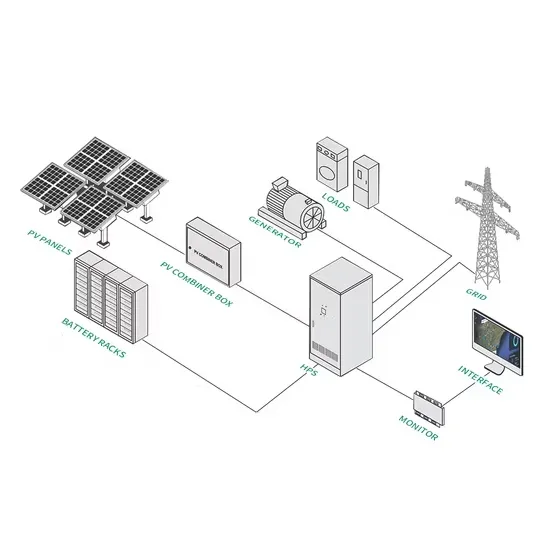

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.