Technical Data

Technical Data DC Input 1) In accordance with IEC 62109-2: I SC PV AC output 2) Depending on the configured country data set Multifunction relay 3) Corresponds to 20

Get a quote

4 Ways of reverse power flow protection in grid

Reverse power protection. Learn how to protect from reverse power flow in a grid-connected PV system and run PV plant without net metering.

Get a quote

Reve-DC: DC reverse

The "DC Reverse" error, also known as "Reve-DC", indicates that one or more of the DC input strings connected to the inverter have reversed polarity. This means the positive (+) and

Get a quote

Application of Anti-Reverse Circuit in Solar System

Therefore, the solar system related equipment is generally designed with anti-reverse connection circuits to ensure that the solar equipment is protected from damage when the input power is

Get a quote

Instruction Manual

B: Battery terminals: Connect to 12V battery (s) or other DC power source. "+" is positive & " - " is negative. Reverse polarity connection will blow internal fuse and may damage inverter

Get a quote

Reverse connection protection inverter circuit

A reverse connection protection inverter circuit belongs to the technical field of solar energy, and comprises a reverse connection protection circuit and an inverter circuit, wherein...

Get a quote

Application of Anti-Reverse Circuit in Solar System

Therefore, the solar system related equipment is generally designed with anti-reverse connection circuits to ensure that the solar equipment is protected

Get a quote

PV Connection Direction Fault

1.Measure the voltage of the photovoltaic panels eck whether the PV string is connected to the inverter in reverse polarity. If yes, wait until the PV string current decreases to below 0.01 A,

Get a quote

FAQ : How to protect DC-DC converter against reverse voltage

Q&A(FAQ) How to protect DC-DC converter against reverse voltage? Avoid the reverse polarity input voltage. It will break the power supply. It is possible to protect the unit from the

Get a quote

How to Install and Wire an Inverter: A Step-by-Step Wiring

Learn how to wire an inverter with this detailed inverter wiring diagram guide. Understand the components and connections needed to properly set up an inverter system for your home or

Get a quote

What Happens When You Run a DC Inverter Compressor

In this video, we perform a live experiment to show exactly what occurs when the wiring connections are reversed, causing the compressor to run reverse.

Get a quote

What is DC PV Solar Combiner Box

A solar combiner box refers to a user being able to connect a certain number of identical specification photovoltaic cells in series, forming individual photovoltaic strings, then

Get a quote

Solar grid tie inverter protection function introduction

Input reverse connection protection: When the positive input terminal and negative input terminal of the solar inverter are reversely connected, the inverter should be able to

Get a quote

Can a DC Inverter Compressor Run in Reverse? Shocking Test

In this video, we explore whether a DC inverter compressor can run in reverse by changing the U, V, and W wiring connections on the IPM PCB. We first demonst...

Get a quote

Connecting the PV Array

Ensure that the open-circuit voltage of the PV array does not exceed the maximum input voltage of the inverter. Connect the assembled DC connectors to the inverter. The DC connectors

Get a quote

Damage to Multiplus due to reverse polarity input

Don''t worry, the reverse polarity is for the DC side (batteries connection) on the AC side the inverter won''t even complain if it is a single phase installation.

Get a quote

How to handle Reverse Polarity issue

1. Purpose: The inverter is susceptible to damage from polarity reverse connection. In order to protect the internal circuit, the inverter will active an alarm and stop for functioning to prevent

Get a quote

Can the input-output polarity of DC-DC converters be reversed

Please refer to the Figures below to see how connections can be made. Information on DC-DC Converters is provided in the form of FAQ.

Get a quote

Solis Seminar 【Episode 46】: Ensuring DC Polarity is Correctly

Reverse polarity of the string is one of the most likely problems in the construction process, and it have serious consequences, such as damage to the inverter and other

Get a quote

VFD Forward Reverse Wiring: A Comprehensive

Posted on 30th Oct 2024 VFD Forward Reverse Wiring: A Comprehensive Guide Variable Frequency Drives (VFDs) are essential for controlling the speed and

Get a quote

SG110CXPV Grid-Connected InverterUser ManualSG110CX

If all of the items mentioned above meet the requirements, proceed as follows to start up the inverter for the first time. step 1 Rotate the DC switch of the inverter to "ON" position. step 2

Get a quote

FAQ : How to protect DC-DC converter against

Q&A(FAQ) How to protect DC-DC converter against reverse voltage? Avoid the reverse polarity input voltage. It will break the power supply. It is possible

Get a quote

How to Install and Wire an Inverter: A Step-by-Step

Learn how to wire an inverter with this detailed inverter wiring diagram guide. Understand the components and connections needed to properly set up an

Get a quote

Welding Polarity: Definition, Types, and How It Affects

When you connect the gun cable to your welder''s positive (+) terminal, we call the polarity DCEP, also known as reverse polarity, and

Get a quote

6 FAQs about [Inverter DC reverse connection]

How does a DC inverter work?

The DC input is usually wired to the battery bank, which provides the power source for the inverter. It is important to connect the positive terminal of the inverter to the positive terminal of the battery and the negative terminal to the negative terminal of the battery, ensuring proper polarity.

What are the components of an inverter?

Inverters typically consist of several components, including input terminals, output terminals, control circuitry, and power conversion circuitry. The input terminals are connected to the DC power source, such as batteries or solar panels, while the output terminals are connected to the AC load.

What is an anti-reverse connection circuit?

Therefore, the solar system related equipment is generally designed with anti-reverse connection circuits to ensure that the solar equipment is protected from damage when the input power is reversed. The simplest anti-reverse circuit is to connect a diode in series with the input circuit, as shown in Figure 1.

What is an inverter used for?

An inverter is an electrical device that converts direct current (DC) power into alternating current (AC) power. It is commonly used in various applications, such as solar power systems, uninterruptible power supplies (UPS), and electric vehicle charging.

How do I choose the right inverter cable & protection sizing?

It is recommended to consult the inverter manufacturer’s manual or guidelines to determine the appropriate cable and protection sizing. The basic wiring diagram for an inverter includes connections for the DC input, AC output, and grounding. The DC input is usually wired to the battery bank, which provides the power source for the inverter.

What is an inverter wiring diagram?

An inverter wiring diagram is a visual representation of how the various components of an inverter system are connected. It shows the flow of electricity from the battery source to the inverter, and then to the loads that are being powered.

Guess what you want to know

-

Photovoltaic inverter reports PV reverse connection

Photovoltaic inverter reports PV reverse connection

-

Mauritius communication base station inverter grid connection

Mauritius communication base station inverter grid connection

-

Andor DC power generation inverter

Andor DC power generation inverter

-

Photovoltaic dual inverter box grid connection

Photovoltaic dual inverter box grid connection

-

How much current does the DC inverter provide

How much current does the DC inverter provide

-

Cambodia communication base station inverter grid connection ranking

Cambodia communication base station inverter grid connection ranking

-

Inverter DC 36V output

Inverter DC 36V output

-

250v DC inverter to 220v

250v DC inverter to 220v

-

Estonian DC panel inverter

Estonian DC panel inverter

-

Latvian communication base station inverter grid connection bidding price

Latvian communication base station inverter grid connection bidding price

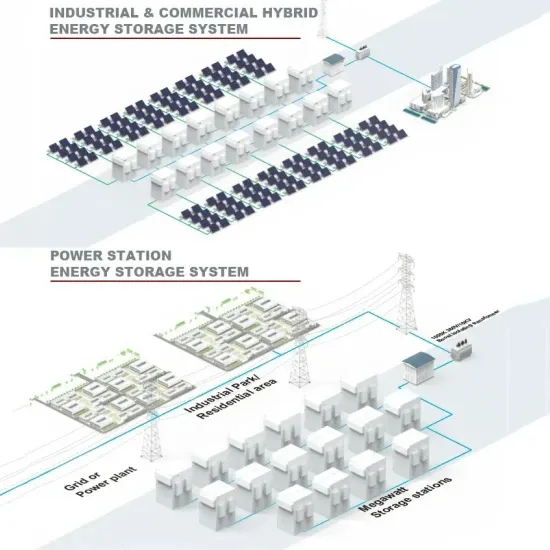

Industrial & Commercial Energy Storage Market Growth

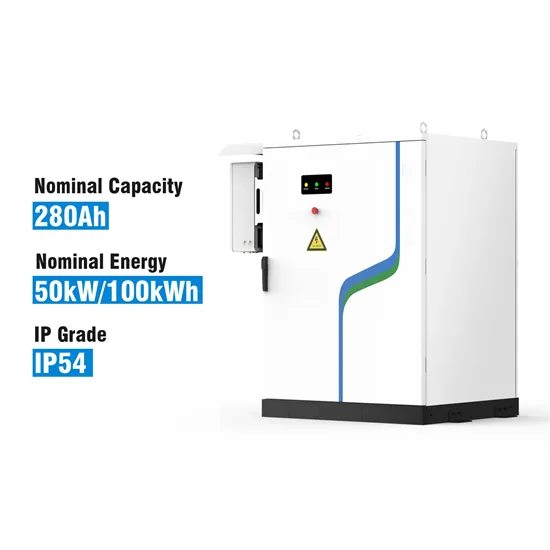

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.