72 Sorter Manufacturers in 2025

72 Sorter Manufacturers in 2025 This section provides an overview for sorters as well as their applications and principles. Also, please take a look at the list of

Get a quote

High-Precision Battery Sorting Machines | TERTRON

Optimize battery production with TERTRON''s automated sorting machines. Featuring high-precision classification by voltage, capacity, and resistance, our user-friendly systems ensure

Get a quote

Top 17 Battery Storage Companies in Japan (2025)

With over 10 years of experience in solar energy and a strong manufacturing base, they ensure high-quality products that may complement their storage

Get a quote

Prismatic Battery Cell Sorting Machine for EV Production

By leveraging the capabilities of lithium-ion prismatic battery cell sorting machines, EV manufacturers can produce battery packs that deliver

Get a quote

Japan Automatic Cylindrical Battery Sorting Machine Market:

These challenges must be overcome for the market to reach its full potential and for manufacturers to capitalize on the growing demand for advanced sorting technologies in

Get a quote

Battery Sorting Machines Suppliers and Manufacturers

We''re one of the leading battery sorting machines manufacturers and suppliers in China, providing the best service. Please feel free to wholesale or buy quality battery sorting machines at

Get a quote

Prismatic Battery Cell Sorting Machine for EV Production

By leveraging the capabilities of lithium-ion prismatic battery cell sorting machines, EV manufacturers can produce battery packs that deliver reliable, long-lasting performance,

Get a quote

Top 17 Battery Storage Companies in Japan (2025) | ensun

With over 10 years of experience in solar energy and a strong manufacturing base, they ensure high-quality products that may complement their storage offerings.

Get a quote

How Lithium Ion Prismatic Battery Cell Sorting Machines Ensure

A Lithium-ion prismatic battery cell sorting machine is a specialized piece of equipment used in the manufacturing of lithium-ion batteries, particularly for electric vehicles

Get a quote

Revolutionizing Battery Management: How Japanese Manufacturing

The leadership of Japanese manufacturing in battery management offers unparalleled opportunities for companies seeking high-quality, innovative solutions. By

Get a quote

Cylindrical Battery Production Line for Efficient

Cylindrical Battery Sorting Machine Tertron''s Cylindrical Battery Sorting Machine efficiently sorts and tests various lithium batteries. It features 11 customizable

Get a quote

Revolutionizing Battery Management: How Japanese

The leadership of Japanese manufacturing in battery management offers unparalleled opportunities for companies seeking high-quality, innovative solutions. By

Get a quote

Top 10 Battery Manufacturers in Japan

In this article, we will explore top 10 battery manufacturers in Japan such as GS Yuasa, Panasonic, Hitachi, Toshiba, NEC, Sanyo, Furukawa Battery, Shin-Kobe Electric

Get a quote

Japanese Commercial Energy Storage Manufacturers: A

Let''s face it – when you think of cutting-edge battery tech, Japan''s commercial energy storage manufacturers might not be the first that come to mind. But hold onto your sushi rolls, because

Get a quote

square aluminum shell battery sorter | Guangdong Sunkalead

Industry Pain Points: Challenges in Traditional Sorting Processes In the era of rapid growth in new energy vehicles, energy storage systems, and consumer electronics, the efficiency and

Get a quote

Lithium Battery Sorting Machine Market: Understanding the

The Global Lithium Battery Sorting Machine Market Is Witnessing Significant Growth As The Demand For Electric Vehicles (Evs), Portable Electronics, And Energy Storage

Get a quote

Battery Cell Sorting Machine Market

Original equipment manufacturers like CATL, LG Energy Solution, Samsung SDI, BYD, and Panasonic typically engage directly with sorting machine suppliers such as Wuxi

Get a quote

Wärtsilä Energy Storage

Our utility-scale energy storage seamlessly integrates with critical energy systems, driving revenue with optimised assets and delivering proven reliability, flexibility, and safety. We have

Get a quote

Lithium Battery Sorting Machine Strategic Insights for 2025 and

Technological advancements leading to improved sorting efficiency, accuracy, and automation are further contributing to market growth. Segmentation by channel capacity reveals a strong

Get a quote

Looking to achieve efficient and precise sorting in your battery

Efficient Sorting: Our sorting machine features high- speed automated sorting capabilities, significantly boosting production efficiency to meet large-scale manufacturing needs.

Get a quote

Japan Cylindrical Battery Sorting Machine Market | By Type

The rise in electric vehicle production in Japan, alongside an increasing reliance on renewable energy, requires consistent supply chains for battery components, making cylindrical battery...

Get a quote

Energy Storage Battery Manufacturing Key Processes – Cell Sorting

Lithium cell sorting is a crucial manufacturing process that categorizes battery cells to ensure maximum consistency in performance across a battery pack. This enhances overall efficiency,

Get a quote

Cylindrical Battery Sorting Machine Market Size, Market Trends

In consumer electronics, cylindrical batteries are crucial for powering devices such as laptops, smartphones, and power tools. Additionally, these sorting machines are critical in renewable

Get a quote

China Battery Cell Sorter Machine for Cylindrical Cell Manufacturers

By accurately assessing and categorizing batteries based on stringent performance metrics, manufacturers can deliver consistent and reliable battery packs suitable for a wide range of

Get a quote

Battery Storage In Japan – Policy Deep Dive

Additionally, the energy storage system can store excess electricity when supply exceeds demand and release it when needed, generating profit from the price difference

Get a quote

Japan Cylindrical Battery Sorting Machine Market | By Type

In the Japanese market, the demand for cylindrical battery sorting machines is driven by the need for accurate sorting and categorization of battery types based on parameters like size,

Get a quote

6 FAQs about [Japanese energy storage battery sorting machine manufacturing]

Why are Japan's Top 10 battery manufacturers important?

The top 10 battery manufacturers in Japan made significant contributions to the rapid growth of lithium-ion, lead acid, and other advanced battery industries. These major companies ensure their products have the best performance and sustainability, making Japan one of the powerhouse in the battery sector.

Who is the best battery manufacturer in Japan?

Mitsunami is one of the top 10 battery manufacturers in Japan which was established in 1959 and has 236.72 million yen in capital. They started their business in selling vacuum tubes, before producing electronic parts for devices such as capacitors, resistors, connectors, etc.

Why is Japan a global player in the battery industry?

Japan is a global player in the battery industry with its manufacturers supplying the needs of global customers and driving innovation in energy storage solutions for various industries. From consumer electronics, electric vehicles, even industrial machinery, Japanese battery manufacturers have products for all these applications.

Where are Panasonic Batteries made?

Panasonic is located in Osaka, Japan and started as an electronic company which produces consumer electronics under the name Matsushita Electric Housewares Manufacturing Works. In 2008, they changed to their current name and have been expanding their business to battery manufacturing.

Where are Furukawa batteries made?

Furukawa Battery started their business in 1950 and is located in Yokohama, Japan. They produce batteries for the automotive industry, commonly used in cars all across Asia. Their main product is lead-acid batteries, lithium-ion batteries, and energy storage systems.

Who makes Toshiba batteries?

Toshiba was founded in 1939 in Tokyo, Japan as one of the leading electronic companies in Japan. As they expanded their business to the battery sector, they produced lithium-ion batteries that became one of their main products. These batteries are commonly used for industrial equipment, energy storage systems, and electric vehicles.

Guess what you want to know

-

Afghanistan Energy Storage Battery Manufacturing Plant

Afghanistan Energy Storage Battery Manufacturing Plant

-

New battery energy storage manufacturing base

New battery energy storage manufacturing base

-

Guyana energy storage battery manufacturing company

Guyana energy storage battery manufacturing company

-

Digital Energy Storage Battery Manufacturing Project

Digital Energy Storage Battery Manufacturing Project

-

Japanese energy storage battery distributor

Japanese energy storage battery distributor

-

Swiss Energy Storage BMS Battery Company

Swiss Energy Storage BMS Battery Company

-

How to choose lithium battery for solar energy storage cabinet

How to choose lithium battery for solar energy storage cabinet

-

Panama Battery Energy Storage Cabinet

Panama Battery Energy Storage Cabinet

-

Lithium iron phosphate battery plus new energy storage

Lithium iron phosphate battery plus new energy storage

-

Danish energy storage battery companies

Danish energy storage battery companies

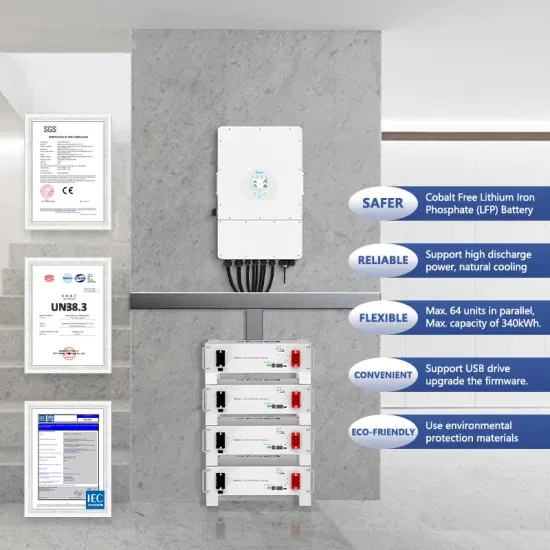

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.