Topping-Out ceremony for MAN''s new battery production facility

From April 2025, the first phase of operations will see up to 50,000 batteries manufactured annually, with plans to increase capacity to 100,000 high-voltage. MAN is

Get a quote

U.S. Department of Energy Selects 11 Projects to Advance

Those selected projects will retrofit, expand, and build new domestic facilities for battery-grade processed critical minerals, battery components, battery manufacturing, and

Get a quote

Top 10 Global BESS Manufacturers – BESSfinder

Introduction The Battery Energy Storage System (BESS) industry has experienced remarkable growth in recent years, driven by the global shift toward renewable energy and the increasing

Get a quote

U.S. Energy Storage Industry Commits $100 Billion Investment in

The American Clean Power Association (ACP), on behalf of the U.S. energy storage industry, announced a historic commitment to invest $100 billion into building and

Get a quote

MAN announces end of works at the company''s

From April 2025, high-voltage batteries will be manufactured industrially in Nuremberg using state-of-the-art production methods on 17,000

Get a quote

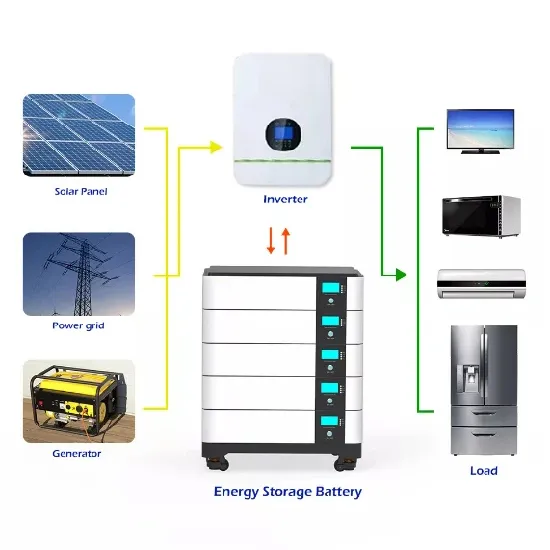

Energy Storage

battery energy storage system (BESS) is a term used to describe the entire system, including the battery energy storage device along with any ancillary motors/pumps, power electronics,

Get a quote

DOE''s $3B Allocation Boosting 25 Advanced Battery Storage Manufacturing

The selected projects, administered by DOE''s Office of Manufacturing and Energy Supply Chains (MESC), will retrofit, expand, and build new domestic facilities for battery-grade processed

Get a quote

Stryten Energy Unveils Plan to Add 10 Gigawatts of

The plan focuses on increasing production across its 11 U.S. manufacturing and battery component plants, where more than 2,500 people

Get a quote

Long-duration Energy Storage | ESS, Inc.

Our new Energy Base product line removes electrolyte volume constraints, allowing for up to 22 hours of energy storage! This breakthrough meets the

Get a quote

Ten new battery plants to double US capacity to 421.5

The United States electric vehicle (EV) industry is on the cusp of a significant milestone, with ten new battery plants poised to open this year.

Get a quote

Topping-Out ceremony for MAN''s new battery

From April 2025, the first phase of operations will see up to 50,000 batteries manufactured annually, with plans to increase capacity to 100,000

Get a quote

New materials big data system + New energy storage industry

For example, in 2023 energy storage system prices fell by half within only two months. In energy storage battery production, capacity utilization plunged from 87 percent in

Get a quote

DOE''s $3B Allocation Boosting 25 Advanced Battery

The selected projects, administered by DOE''s Office of Manufacturing and Energy Supply Chains (MESC), will retrofit, expand, and build new domestic facilities

Get a quote

MAN celebrates topping-out ceremony for new battery production

From April 2025, the delivered modules will be inserted into battery layers in large series production. These layers will be stacked on top of each other to form the battery pack and then

Get a quote

FINAL SEIA Energizing Battery Storage Manufacturing

It is essential to the nation''s continued economic health, global competitiveness and energy security to quickly address our overdependence on solar and energy storage component

Get a quote

North America''s EV Battery Manufacturing and Energy Storage

Discover the top EV battery manufacturing and energy storage projects currently underway or slated for construction in North America. Read now!

Get a quote

U.S. Department of Energy Selects 11 Projects to

Those selected projects will retrofit, expand, and build new domestic facilities for battery-grade processed critical minerals, battery

Get a quote

11 New Battery Technologies To Watch In 2025

We explore cutting-edge new battery technologies that hold the potential to reshape energy systems, drive sustainability, and support the

Get a quote

Ten new battery plants to double US capacity to 421.5 GWh for

The United States electric vehicle (EV) industry is on the cusp of a significant milestone, with ten new battery plants poised to open this year.

Get a quote

Stryten Energy Unveils Plan to Add 10 Gigawatts of New U.S. Energy

The plan focuses on increasing production across its 11 U.S. manufacturing and battery component plants, where more than 2,500 people produce batteries for multiple

Get a quote

US zinc BESS manufacturer Eos guides for tenfold

Image: Eos Energy Enterprises via X. Zinc hybrid cathode battery and storage system maker Eos Energy Enterprises expects 2025 revenues to

Get a quote

Tracking the EV battery factory construction boom

The complex will have two manufacturing facilities — one dedicated to cylindrical batteries for EVs and another for lithium iron phosphate pouch

Get a quote

MAN announces end of works at the company''s battery

From April 2025, high-voltage batteries will be manufactured industrially in Nuremberg using state-of-the-art production methods on 17,000 square metres. Up to 50,000

Get a quote

Tracking the EV battery factory construction boom across North

The complex will have two manufacturing facilities — one dedicated to cylindrical batteries for EVs and another for lithium iron phosphate pouch-type batteries for energy

Get a quote

Top 10 energy storage cell manufacturers in China

The article will explore the top 10 energy storage cell manufacturers in China including CATL, BYD, EVE, REPT, Hithium, GOTION HIGH-TECH, NARADA,

Get a quote

New National Energy Storage Hub Will Enable

The U.S. Department of Energy announced the creation of two new Energy Innovation Hubs led by DOE national laboratories across the country.

Get a quote

AESC | U.S. Locations | AESC Group''s Investment 30GWh South

AESC Group is a global battery technology company headquartered in Zama, Japan, and committed to research, development, design, manufacturing and sales of power batteries for

Get a quote

6 FAQs about [New battery energy storage manufacturing base]

What is a platform for next-generation battery manufacturing?

Platforms for Next-Generation Battery Manufacturing Subtopic 1 focuses on advanced processes and/or high-performance processing machines for low cost, large-scale, sustainable, commercial manufacture of sodium-ion batteries.

What is a battery manufacturing project?

These projects will advance platform technologies upon which battery manufacturing capabilities can be built, enabling flexible, scalable, and highly controllable battery manufacturing processes.

Where are high-voltage batteries made?

From April 2025, high-voltage batteries will be manufactured industrially in Nuremberg using state-of-the-art production methods on 17,000square metres. This will create almost 350 new jobs for the future. MAN will be the first commercial vehicle manufacturer to start its own battery series production in Germany.

What are smart manufacturing platforms for battery production?

Smart Manufacturing Platforms for Battery Production This topic emphasizes development of broadly applicable smart manufacturing platforms that can be leveraged to improve the production of a variety of battery technologies. For a full list of projects click here.

How many batteries will man produce in 2025?

From April 2025, the first phase of operations will see up to 50,000 batteries manufactured annually, with plans to increase capacity to 100,000 high-voltage. MAN is investing around €100 million in the new facility, covering costs for logistics, infrastructure, buildings, and production systems.

Does GM have a battery plant?

The automaker in April 2023 announced a joint venture with Samsung SDI to build a new battery plant in the United States. Aside from volume production, GM has also partnered with startup SolidEnergy Systems in 2021 to build a prototyping facility in Woburn, Massachusetts.

Guess what you want to know

-

New energy storage communication base station lead-acid battery

New energy storage communication base station lead-acid battery

-

Energy Storage Battery Cabinet Overview Base Station

Energy Storage Battery Cabinet Overview Base Station

-

Base station lithium battery energy storage 100kw inverter manufacturer

Base station lithium battery energy storage 100kw inverter manufacturer

-

Tanzania base station energy storage battery life

Tanzania base station energy storage battery life

-

Andorra energy-saving new energy storage battery

Andorra energy-saving new energy storage battery

-

Finland s communication base station energy storage battery solution

Finland s communication base station energy storage battery solution

-

Zambia recruits battery energy storage for telecommunication base stations

Zambia recruits battery energy storage for telecommunication base stations

-

Pakistan adds 6 25MWh of energy storage systems to new communication base stations

Pakistan adds 6 25MWh of energy storage systems to new communication base stations

-

Solomon Islands new energy battery cabinet base station power generation

Solomon Islands new energy battery cabinet base station power generation

-

Dominica s new vanadium titanium GW-grade all-vanadium liquid flow energy storage battery

Dominica s new vanadium titanium GW-grade all-vanadium liquid flow energy storage battery

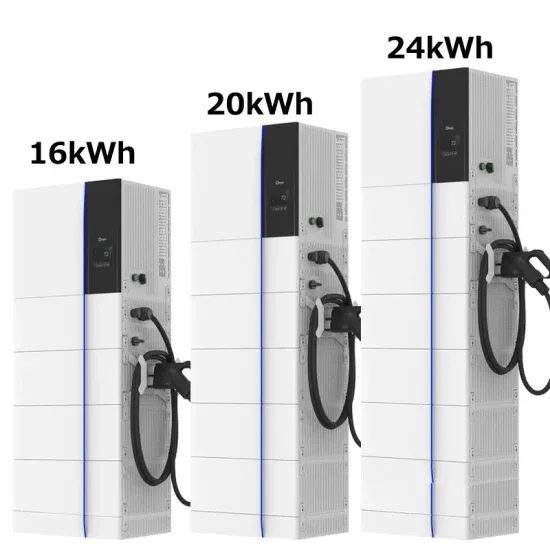

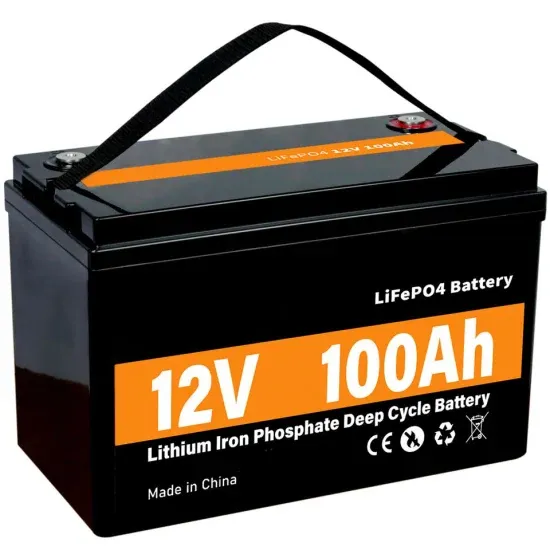

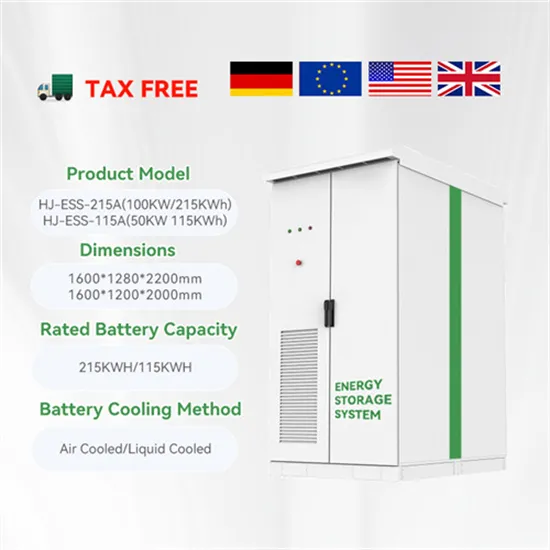

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.