Lithium-Ion Battery Pack Manufacturing Process Guide

The process of lithium-ion battery pack manufacturing involves meticulous steps from cell sorting to final testing and assembly. Each phase plays a critical role in ensuring the

Get a quote

PRODUCTION PROCESS OF BATTERY MODULES AND

Several modules and other electrical, mechanical and thermal components are assembled into a pack. Battery value chain. Overview of the production sequence from cell to system. 60% 80%

Get a quote

What Is the Process of Lithium-Ion Battery Pack Assembly

So, what are the process flows of a lithium battery pack production line? Here, we break down the primary steps involved in this intricate process. Each step is crucial to

Get a quote

How to Build a Lithium Ion Battery Pack: Expert Guide for Engineers

Building lithium-ion battery packs requires systematic engineering across multiple disciplines, from cell selection to safety compliance. Here are the essential insights every

Get a quote

Megapack – Utility-Scale Energy Storage | Tesla

Megapack is a utility-scale battery that provides reliable energy storage, to stabilize the grid and prevents outages. Find out more about Megapack.

Get a quote

Behind the Scenes: The Flow of a Lithium Battery Pack

Lithium battery packs are the workhorses that power our electronics, but their creation involves a complex dance of several processes. Let''s delve into the typical flow of a

Get a quote

What Is the Process of Lithium-Ion Battery Pack

So, what are the process flows of a lithium battery pack production line? Here, we break down the primary steps involved in this intricate process.

Get a quote

Lithium Battery PACK Production Line Processes and Equipment

Our engineering team offers design solutions. The Lithium Battery PACK production line encompasses processes like cell selection, module assembly, integration, aging tests, and

Get a quote

Lithium Ion Battery Pack factory

China Lithium Ion Battery Pack manufacturer, Shenzhen BAK Technology Co., Ltd. is Li Polymer Battery Pack factory, offering quality products at factory prices.

Get a quote

Design, Optimization, and Analysis of Electric vehicle Battery

The battery thermal management technology in electric vehicles (EVs) and hybrid electric vehicles (HEVs) should keep temperatures within a proper range of 15 0C to 40 0C to keep lithium-ion

Get a quote

Amazon : Lithium Power Pack

Amazon : lithium power packPortable Charger Power Bank - 60,000mAh Battery Pack, 22.5W Fast Charging Phone Charger with USB-C/iOS/Micro-USB Cable, Powerbank for iPhone 16 15

Get a quote

Lithium-ion Battery Module and Pack Production Line

The process flow of Li-ion module and pack production line can be divided into the following main steps: 1. Entering the Production Line and Sorting.

Get a quote

Key Points of Lithium Battery PACK Manufacturing

From selecting and matching battery cells to assembling, testing, and packaging, discover the key steps involved in creating high-quality lithium

Get a quote

Behind the Scenes: The Flow of a Lithium Battery

Lithium battery packs are the workhorses that power our electronics, but their creation involves a complex dance of several processes.

Get a quote

Lithium Battery PACK Production Line Processes and

Our engineering team offers design solutions. The Lithium Battery PACK production line encompasses processes like cell selection, module assembly,

Get a quote

The Ultimate Guide For Lithium-Ion Battery Packs

This in-depth guide explores lithium-ion battery packs from the inside out. Learn about the key components like cells, BMS, thermal management, and enclosure.

Get a quote

China revises guidelines for lithium-ion battery industry

China''s Ministry of Industry and Information Technology on Wednesday unveiled revised guidelines for the lithium-ion battery industry to further strengthen standardized

Get a quote

Lithium Battery Pack manufacturing Production Line

3 days ago· A lithium battery pack manufacturing production line is designed to efficiently produce highquality lithiumion or lithium ferro phosphate (LFP) battery packs, which are

Get a quote

Custom Lithium Battery Pack Manufacturing

Manufacturing custom lithium-ion battery packs requires precise engineering, quality control, and safety standards. The process involves gathering requirements, selecting cells, concurrent

Get a quote

Lithium-Ion Battery Pack Manufacturing Process Guide

The process of lithium-ion battery pack manufacturing involves meticulous steps from cell sorting to final testing and assembly. Each phase

Get a quote

Integration issues of lithium-ion battery into electric vehicles

In this work, the integration of Lithium-ion battery into an EV battery pack is investigated from different aspects, namely different battery chemistry, cell packaging, electric

Get a quote

Robot Lithium Battery Solution

The lithium battery packs produced by Febatt meet the requirements of international safety certifications such as UL and CE, ensuring the safety of products on a global scale.

Get a quote

Lithium-ion Battery Pack Manufacturing Process & Design

This guide discussed the lithium battery pack anufacturing process, battery pack design, and the impact of technological advancements.

Get a quote

How to Build a Lithium Ion Battery Pack: Expert Guide for Engineers

What are the key components needed to build a lithium-ion battery pack? The key components include lithium-ion cells (cylindrical, prismatic, or pouch), a battery management

Get a quote

Key Points of Lithium Battery PACK Manufacturing Process

From selecting and matching battery cells to assembling, testing, and packaging, discover the key steps involved in creating high-quality lithium-ion battery packs. Learn about

Get a quote

LiFePO4 Lithium Battery Pack System: Applications and

In view of the requirements for industrial lithium batteries miniaturization and low cost, many similar applications mostly use 18650 cells, and the operating voltage is generally

Get a quote

Lithium-ion Battery Module and Pack Production Line Process Flow

The process flow of Li-ion module and pack production line can be divided into the following main steps: 1. Entering the Production Line and Sorting.

Get a quote

6 FAQs about [Pack lithium battery enterprise operation]

How to contact lithium battery pack engineering team?

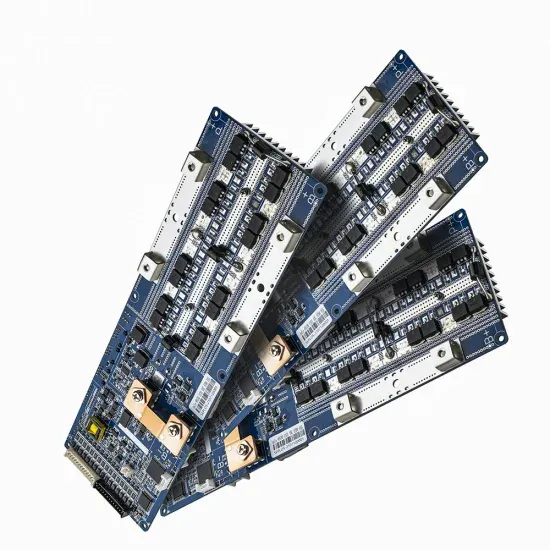

Tel & Wechat: (0086) 158 6765 3608 Mr.Pan Our engineering team offers design solutions. The Lithium Battery PACK production line encompasses processes like cell selection, module assembly, integration, aging tests, and quality checks, utilizing equipment such as laser welders, testers, and automated handling systems for efficiency and precision.

What is a lithium battery pack?

The Lithium Battery PACK line is a crucial part of the lithium battery production process, encompassing cell assembly, battery pack structure design, production processes, and testing and quality control. Here is an overview of the Lithium Battery PACK line: Cell Types Cells are the basic units that make up the battery pack, mainly divided into:

What is a lithium-ion battery module & pack production line?

The lithium-ion battery module and pack production line is a complex system consisting of multiple major units and associated equipment that work in concert to achieve high quality lithium-ion module and pack production.

How do you make custom lithium-ion battery packs?

Key Takeaway: Manufacturing custom lithium-ion battery packs requires precise engineering, quality control, and safety standards. The process involves gathering requirements, selecting cells, concurrent engineering, prototyping, certification, production planning, and lifecycle support.

Why should you choose a lithium-ion battery module & pack line?

The whole system has no leakage of electricity, water, liquid or gas, which ensures the safety and stability of the production process. The lithium-ion battery module and pack line is a key component in the field of modern battery technology. Its high degree of automation and rigorous process flow ensure high quality and efficiency in production.

What are the production processes of a battery pack?

Outer Packaging: Provides physical protection. Output Interfaces: For connecting the battery pack with external devices. Production processes cover cell selection and grouping, welding, assembly, aging testing, inspection, and packaging. Assembly Production Line The process flow of the PACK production line includes:

Guess what you want to know

-

Lithium battery pack module

Lithium battery pack module

-

The last cell of the lithium battery pack

The last cell of the lithium battery pack

-

What is the charging voltage of a 36v lithium battery pack

What is the charging voltage of a 36v lithium battery pack

-

Chad lithium iron phosphate battery pack wholesale

Chad lithium iron phosphate battery pack wholesale

-

Central African Republic pack lithium battery

Central African Republic pack lithium battery

-

Lithium battery pack outer box container base station

Lithium battery pack outer box container base station

-

Zimbabwe lithium battery pack customization

Zimbabwe lithium battery pack customization

-

How long does it take to charge a lithium battery pack

How long does it take to charge a lithium battery pack

-

Removable lithium battery pack

Removable lithium battery pack

-

Ukrainian solar lithium battery pack price

Ukrainian solar lithium battery pack price

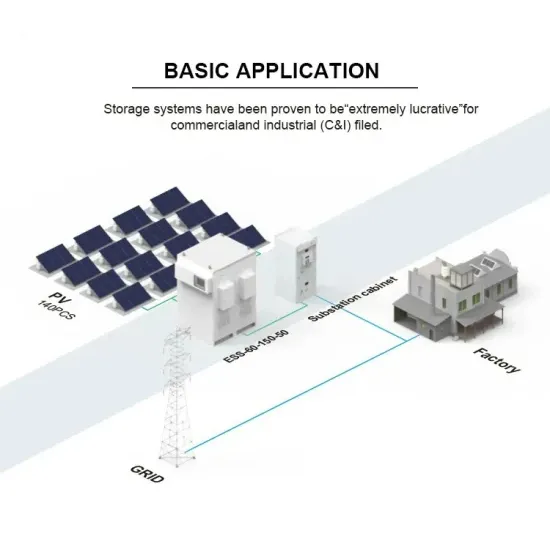

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

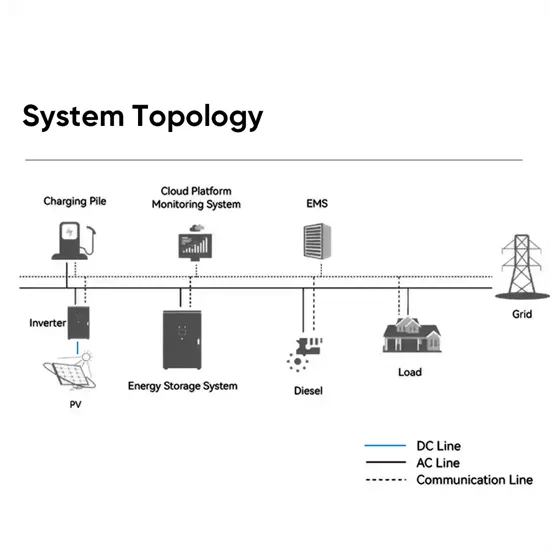

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.