What is a ESS Container

An energy storage system container or ESS container is a storage facility mainly fabricated from metal or shipping containers to store battery banks. The containerized ESS systems host

Get a quote

Assembly Line for Battery Energy Storage System (BESS)

Provides real-time tracking, analytics, and complete traceability of battery packs. It includes data logging and monitoring, assembly station display, customizable views, and report generation

Get a quote

NSN 8145-01-628-2425 Special Purpose Prefabricated Building

NSN 8145-01-628-2425 special purpose prefabricated building and equipment. ap104016 battery conex contains the following; 100907 20'' dry box; 301052 fan lpe12va(2); 32004 4''x8''

Get a quote

HOW TO DESIGN A BESS (BATTERY ENERGY STORAGE SYSTEM) CONTAINER?

Design the container layout to accommodate the battery modules, inverters, transformers, HVAC systems, fire suppression systems, and other necessary equipment. Plan

Get a quote

Containerized Battery Energy Storage System (BESS): 2024 Guide

Containerized Battery Energy Storage Systems (BESS) are essentially large batteries housed within storage containers. These systems are designed to store energy from

Get a quote

BESS Assemblies: A Comprehensive Guide to the Complex

BESS stands for state-of-the-art energy storage systems and makes a very basic contribution to the integration of renewable energy sources and the stabilization of the grid. A BESS is

Get a quote

Energy storage container battery assembly drawings

The Battery Energy Storage System (BESS) container design sequence is a series of steps that outline the design and development of a containerized energy storage system.

Get a quote

How to Assemble a Battery Pack with a BMS Module

Learn how to safely assemble a battery pack with a BMS module. Our step-by-step guide covers materials needed, safety precautions, detailed

Get a quote

Mastering the Battery Pack Assembly Process: A

Conclusion The battery pack assembly process is a sophisticated and highly specialized field that underpins the success of modern energy

Get a quote

Detailed Understanding of the Containerized Battery System

What is a battery system that is containerized? A modular, pre-assembled energy storage system that can be easily deployed and transported in a regular shipping container.

Get a quote

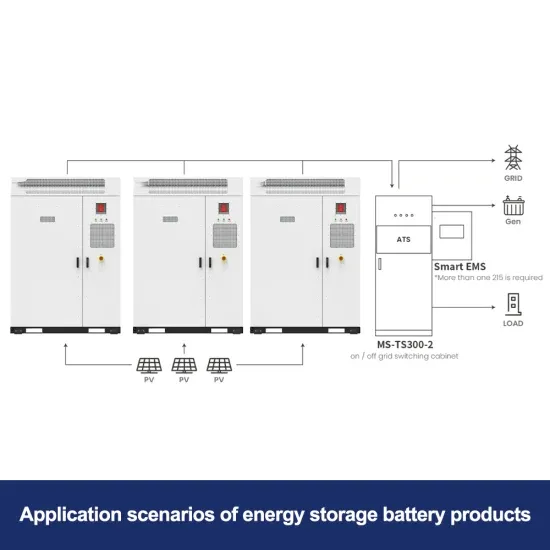

Energy storage container assembly line process standards

Energy Storage Container is an energy storage battery system, which includes a monitoring system, battery management unit, particular fire protection system, special air conditioner,

Get a quote

Container Design for Battery Energy Storage System (BESS)

Learn how we optimized design of a battery storage system container to reduce weight, ensure structural integrity, and achieve efficient thermal regulation.

Get a quote

Lithium-Ion Battery Assembly Process & Key Stages

Discover the key stages in the lithium-ion battery assembly process, from raw materials to pack assembly. Learn how battery-making

Get a quote

PartsSource — Medical Supplies, Equipment & Repair :

PartsSource offers a digital approach to the healthcare supply chain. Explore our end-to-end solutions from ordering and delivery to maintenance and repair.

Get a quote

Utility-scale battery energy storage system (BESS)

In the 4 MWh BESS reference design, TVOC-2 is installed inside each battery container and in the power container where the PCS, transformer and substation are installed.

Get a quote

Container Design for Battery Energy Storage System

Learn how we optimized design of a battery storage system container to reduce weight, ensure structural integrity, and achieve efficient thermal regulation.

Get a quote

5MWh Battery Storage Container (eTRON BESS)

AceOn offer one of the worlds most energy dense battery energy storage system (BESS). Using new 314Ah LFP cells we are able to offer a high capacity

Get a quote

BESS Assemblies: A Comprehensive Guide to the Complex

The following guide to BESS assembly is very informative, covering all the key components involved, stages of assembly, safety protocols, and a few key considerations that must be

Get a quote

(PDF) BATTERY MODULE AND PACK ASSEMBLY

Our second brochure on the subject "Assembly process of a battery module and battery pack" deals with both battery module assembly and

Get a quote

No Grid Power? The HJ-SG Solar Container Keeps Base Stations

HJ-SG Solar Container provides reliable off-grid power for remote telecom base stations with solar, battery storage and backup diesel in one plug-and-play solution.

Get a quote

How to Assemble a Battery Pack with a BMS Module | Step-by

Learn how to safely assemble a battery pack with a BMS module. Our step-by-step guide covers materials needed, safety precautions, detailed assembly instructions, and testing

Get a quote

6 FAQs about [Battery assembly set container base station]

What is a containerized battery energy storage system?

Containerized Battery Energy Storage Systems (BESS) are essentially large batteries housed within storage containers. These systems are designed to store energy from renewable sources or the grid and release it when required. This setup offers a modular and scalable solution to energy storage.

How do I design a battery energy storage system (BESS) container?

Designing a Battery Energy Storage System (BESS) container in a professional way requires attention to detail, thorough planning, and adherence to industry best practices. Here's a step-by-step guide to help you design a BESS container: 1. Define the project requirements: Start by outlining the project's scope, budget, and timeline.

What is a battery energy storage system (BESS)?

The amount of renewable energy capacity added to energy systems around the world grew by 50% in 2023, reaching almost 510 gigawatts. In this rapidly evolving landscape, Battery Energy Storage Systems (BESS) have emerged as a pivotal technology, offering a reliable solution for storing energy and ensuring its availability when needed.

What is a battery energy storage system?

Battery Energy Storage Systems (BESS) are key players in the energy transition: they enable electricity to be stored and thus, on the one hand, they compensate for the non-programmability of new renewable sources (the Sun and the wind) and, on the other hand, they promote grid stability.

What are the challenges in designing a battery energy storage system container?

The key challenges in designing the battery energy storage system container included: Weight Reduction: The container design had to be lightweight yet strong enough to withstand operational stresses like shocks and seismic forces, ensuring the batteries were protected during transport and deployment.

How to optimize battery storage system performance and safety?

To ensure optimal performance and safety of battery storage system, effective thermal management was a key consideration in the design. We integrated an efficient HVAC system into the container design by: Incorporating two AC chillers to cool the battery area, regulating the temperature inside the container.

Guess what you want to know

-

New Energy Battery Communication Power Supply Container Base Station

New Energy Battery Communication Power Supply Container Base Station

-

Wall-mounted battery cabinet base station set

Wall-mounted battery cabinet base station set

-

Battery high temperature aging container base station

Battery high temperature aging container base station

-

Battery station cabinet container base station

Battery station cabinet container base station

-

Nepal battery price container base station

Nepal battery price container base station

-

Communication base station battery 48v used in container communication base station

Communication base station battery 48v used in container communication base station

-

Energy Storage Container Battery System ESS Power Base Station

Energy Storage Container Battery System ESS Power Base Station

-

Silicon negative electrode battery container base station

Silicon negative electrode battery container base station

-

Lead-acid battery manufacturing ESS power base station container

Lead-acid battery manufacturing ESS power base station container

-

Energy storage battery container price base station

Energy storage battery container price base station

Industrial & Commercial Energy Storage Market Growth

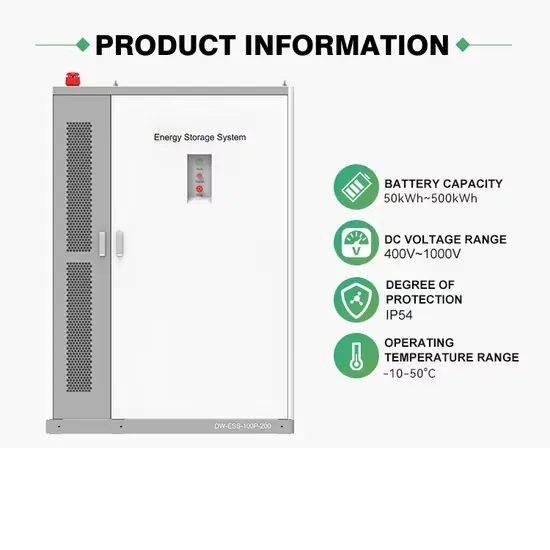

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.