Comprehensive study of high-temperature calendar aging on

A comprehensive study of high-temperature aging on cylinder Li-ion battery is carried out through multi-level analysis from centimeter scale to nanometer scale, where

Get a quote

Dynamic Overcharge Performance and Mechanism of Lithium-Ion

In this content, this work investigates the evolution of overcharge performances and underlying mechanism during high-temperature calendar aging. The findings reveal that

Get a quote

Dynamic Overcharge Performance and Mechanism of

In this content, this work investigates the evolution of overcharge performances and underlying mechanism during high-temperature calendar

Get a quote

Important Application of Thermal Cameras in Battery High-Temperature

Important Application of Thermal Cameras in Battery High-Temperature Aging Tests"Aging" is an indispensable process and also a process with the highest risks in the battery production

Get a quote

Heat Generation and Degradation Mechanism of Lithium-Ion

High-temperature aging can cause the cell to degrade, resulting in the deterioration of the electrochemical performance of the cell, and further afecting the heat generation characteristics.

Get a quote

Heat Generation and Degradation Mechanism of Lithium-Ion

High-temperature aging has a serious impact on the safety and performance of lithium-ion batteries. This work comprehensively investigates the evolution of heat generation

Get a quote

What is Accelerated Aging Testing

Accelerated aging testing is essential for manufacturers aiming to produce high-quality, reliable products. Whether for medical devices, aerospace components, electronics, or

Get a quote

Novel Power Allocation Approach in a Battery Storage

This paper proposed a novel power allocation approach for multiple battery containers in a battery energy storage station considering

Get a quote

How Battery Charging and Discharging Works

Quality Assurance Best Practices Conclusion Frequently Asked Questions About Battery Charging and Discharging What''s the ideal charging percentage for maximum battery

Get a quote

Effect of Temperature on the Aging rate of Li Ion Battery

Temperature is known to have a significant impact on the performance, safety, and cycle lifetime of lithium-ion batteries (LiB). However, the comprehensive effects of temperature on the cyclic

Get a quote

Aging and post-aging thermal safety of lithium-ion batteries under

Understanding and analyzing the aging mechanisms and causes of lithium-ion batteries is crucial for enhancing battery reliability, safety, and longevity, especially considering

Get a quote

Novel Power Allocation Approach in a Battery Storage Power Station for

This paper proposed a novel power allocation approach for multiple battery containers in a battery energy storage station considering batteries'' state of charge,

Get a quote

CTECHI 5G Telecom Base Station Battery 48V 50Ah

CTECHI 5G Telecom Base Station Battery 48V 50Ah Power System Solution UPS Backup Battery The CTECHI 50Ah 48V LiFePO4 Battery is a high

Get a quote

Comprehensive Guide to Battery Aging Cabinet and Temperature

Through long-term charge-discharge cycling and temperature changes, it tests the reliability, stability, and lifespan of the battery packs. The main equipment includes the Battery Aging

Get a quote

Ultimate Guide to Battery Aging

Battery aging is complex, non-linear and influenced by many factors. It is common to split aging into three buckets: calendric, cyclic, and reversible aging.

Get a quote

WO2017144120A1

The invention relates to a method of performing a high-temperature aging process of a lithium-ion cell (10) comprising an anode (12), a cathode (16), an electrolyte (22) and a separator (20),...

Get a quote

Theory of battery ageing in a lithium-ion battery: Capacity fade

Identifying ageing mechanism in a Li-ion battery is the main and most challenging goal, therefore a wide range of experimental and simulation approaches have provided

Get a quote

Lithium-ion battery aging mechanisms and diagnosis method for

In this paper, we systematically summarize mechanisms and diagnosis of lithium-ion battery aging. Regarding the aging mechanism, effects of different internal side reactions on

Get a quote

A Guide to Lithium Battery Temperature Ranges for

The ideal operating temperature range for lithium batteries is 15°C to 35°C (59°F to 95°F). For storage, it is best to keep them in a temperature

Get a quote

Can You Leave a Lipo Battery Charging Overnight

No, you should never leave a Lipo battery charging unattended overnight. These high-performance batteries require careful handling to prevent dangerous failures. Many

Get a quote

Heat Generation and Degradation Mechanism of

High-temperature aging has a serious impact on the safety and performance of lithium-ion batteries. This work comprehensively investigates

Get a quote

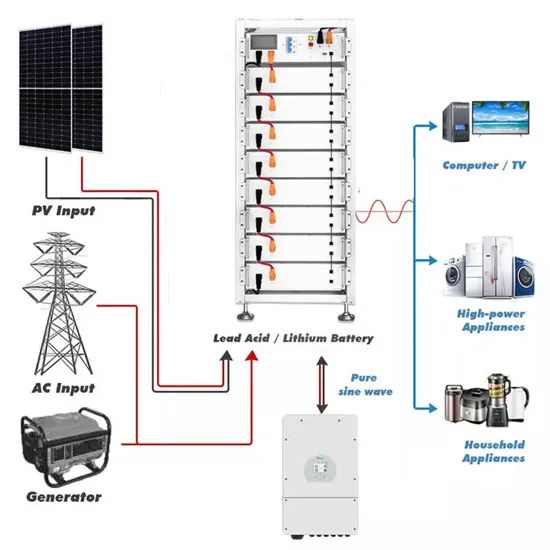

Container base station energy room

Container-type energy base station: It is a large-scale outdoor base station, which is used in scenarios such as communication base stations, smart cities, transportation, power systems

Get a quote

Study on the temperature rise characteristics of aging lithium-ion

The temperature rise at the edge of cell 2 and cell 1 with more serious aging is higher, while the temperature rise at the center of cell 3 with the smallest aging degree is

Get a quote

High-temperature calendar aging at low state-of-charge:

Methodological analysis of capacity degradation mechanisms and thermal runaway propensity under low-SOC aging conditions is essential for establishing optimized

Get a quote

Proceedings of

Battery aging could result in capacity degradation and power degradation, which can be affected by charge/discharge rate, temperature, SOC, overcharge and over discharge, high depth of

Get a quote

Effect of Temperature on the Aging rate of Li Ion Battery

We use an electrochemistry-based model (ECBE) here to measure the effects on the aging behavior of cycled LiB operating within the temperature range of 25 °C to 55 °C.

Get a quote

6 FAQs about [Battery high temperature aging container base station]

How does high-temperature aging affect lithium-ion batteries?

High-temperature aging has a serious impact on the safety and performance of lithium-ion batteries. This work comprehensively investigates the evolution of heat generation characteristics upon discharging and electrochemical performance and the degradation mechanism during high-temperature aging.

Do aging batteries have thermal safety?

Current research primarily analyzes the aging condition of batteries in terms of electrochemical performance but lacks in-depth exploration of the evolution of thermal safety and its mechanisms. The thermal safety of aging batteries is influenced by electrode materials, aging paths, and environmental factors.

How does high-temperature aging affect battery aging?

The aging mechanism of high temperature is investigated under various scales. Incremental capacity (IC) curves depict the deterioration of electrodes and increase of ohmic resistance. Computational Tomography (CT) reveals structure evolution of aged battery at millimeter scale, indicating gas generation after high-temperature aging.

Does high-temperature aging affect cylinder Li-ion batteries?

A comprehensive study of high-temperature aging on cylinder Li-ion battery is carried out through multi-level analysis from centimeter scale to nanometer scale, where intrinsic connection between cell degradation and electrodes deterioration is revealed. 1. Introduction

Does storage temperature affect the aging of LFP batteries?

M. Kassem et al. investigated the impact of different storage temperatures (30 °C, 45 °C, and 60 °C) and SOCs (30 %, 65 %, and 100 %) on the calendar aging of LFP batteries over 8 months, finding significant capacity fade at higher storage temperatures, with side reactions at the anode being the main cause.

Are low-temperature aged batteries better than fresh batteries?

The thermal stability of low-temperature aged batteries is lower than that of fresh batteries , with lithium plating on the anode surface identified as the fundamental cause of worsened thermal runaway performance post low-temperature cycling .

Guess what you want to know

-

Indonesia container communication base station battery

Indonesia container communication base station battery

-

Battery station cabinet container base station

Battery station cabinet container base station

-

Communication base station battery 48v used in container communication base station

Communication base station battery 48v used in container communication base station

-

Sodium-sulfur battery mechanism container base station

Sodium-sulfur battery mechanism container base station

-

Battery container base station

Battery container base station

-

Lead-acid battery charging container base station

Lead-acid battery charging container base station

-

Lithium battery pack outer box container base station

Lithium battery pack outer box container base station

-

Energy Storage Container Battery System ESS Power Base Station

Energy Storage Container Battery System ESS Power Base Station

-

Niue battery replacement site container communication base station

Niue battery replacement site container communication base station

-

Energy storage battery container price base station

Energy storage battery container price base station

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.