DC Arc Faults and PV System Safety

To extinguish a series DC arc, power production must be ceased and current flow in the DC circuit must be reduced to a very low level. It is preferable to reduce the DC current

Get a quote

Arc Fault Circuit Interrupter (AFCI) for PV Systems Technical

Huawei Technologies Co., Ltd. (Huawei for short) has launched inverters with the intelligent DC arc detection (AFCI) function for distributed (including residential) PV systems. As of May

Get a quote

DC Arc Flash on Photovoltaic Equipment

Arc flash on the dc side of a PV system can occur while the inverter is connected to a utility grid. Furthermore, discharge from the capacitors in the inverter can also feed the arc.

Get a quote

PowerPoint Presentation

HIGH AC ARC FLASH AT INVERTER TERMINALS Most BESS GSU transformers are spec''d by the inverter manufacturers. Most transformers are large to save cost, sometimes with many

Get a quote

Century by Lincoln Electric Inverter Arc 120 DC Arc Welder, Inverter

The Century Inverter Arc® 120 Stick Welder is compact for portability and has a 10 to 90 amp output that supports mild steel stick electrode diameters from 1/16in. to 1/8in. The smooth arc

Get a quote

DC Arc Welding Inverter 200A, 8.2 KVA, 0.75PF | Ronix Tools

Ronix DC Arc Welding Inverter 200A, 9.5 KVA is a power tool equipped with IGBT technology helping users with providing for a better welding quality and greater welding penetration, it

Get a quote

A Review of DC Arc Fault Diagnosis in Photovoltaic Inverter

Photovoltaic inverters, as key devices, play an important role in converting DC energy to AC energy. However, arcing faults may occur due to aging, damage, or poor contact

Get a quote

Arccaptain ARC200 Easy to Use DC Stick Welder

The ARC200 is a integrated Inverter 200 Amps Syn stick Welder for beginners, which has good welding performance has two welding modes including lift

Get a quote

Methods for Evaluating DC Arc Incident Energy in PV

The aim of this paper is to discuss the basic principle s of PV systems such as their current-voltage (I-V) and power-voltage (P-V) characteristic curves and explain how they should be

Get a quote

A Review of DC Arc Fault Diagnosis in Photovoltaic Inverter

Among them, detecting DC arc faults in PV inverters is one of the key points to ensure the safe and effective working of PV power generation systems. The PV inverter is a key device for

Get a quote

WELDARC 200AMP DC ARC INVERTER (220V) WITH CABLE KIT

In summary, this portable inverter DC arc welder is designed to provide a convenient and efficient solution for DIY enthusiasts and individuals involved in light maintenance tasks. Its features,

Get a quote

Research on DC arc fault detection in PV systems based on

A string PV plant, including 20 PV modules and one three-phase inverter, is built to acquire current noise information in regular operation and series DC arc faults.

Get a quote

2003 DC Arc Fault

Inverter,AlarmSuggestion Check whether the string cables arc or are in poor contact. The following is the mapping between PV strings and alarm cause IDs: [IDs 1–n

Get a quote

Inverter arc detection

The inverter continuously performs arc detection while producing power. If an electric arc is detected, the inverter stops producing power, and an error code is displayed on the LCD or in

Get a quote

Inverter Welding Machines: Advantages and Applications in the

Learn about the benefits and applications of inverter welding machines in the welding industry. Discover why welding companies choose to use these advanced welders and how they differ

Get a quote

DC Arc Faults and PV System Safety

Within the PV industry, the risk presented by DC arc faults is gaining significant attention, and for good reason. The DC circuits within a PV installation can generate, and

Get a quote

Designing for arc flash mitigation in solar photovoltaic systems

For improved safety, the solar industry is looking to inverter manufacturers to offer dc arc flash mitigation options in the future. Currently, the only available method to reduce arc

Get a quote

How to Troubleshoot DC Arc Faults : RNWBL Service Line

Basic guide on how to troubleshoot DC arc faults, DC AFCI errors, regardless of inverter manufacturer as long as they are UL1699B compliant.

Get a quote

ARC-200DC, 200 Amp Stick Arc Lift-TIG Inverter Welder, 80

This AMICO POWER ARC-200 Pro. Stick Arc DC Inverter Welder Voltage Welding Machine delivers a flawless weld, making spatter and post-weld cleanup easy.

Get a quote

A DC Arc Fault Detection Method Based on AR Model for

An arc fault detection method based on the autoregressive (AR) model is proposed. A test platform collects the database of this research according to the UL1699B

Get a quote

Ultimate Guide to PV DC Arc-Fault Detection and Mitigation

4 days ago· According to the IEA''s discussion of availability and protection in System Integration of Renewables, inverters may trip on ground or arc faults, and removing nuisance trips helps

Get a quote

6 FAQs about [DC Arc Inverter]

What are PV inverter arc faults?

Arc faults not only reduce the efficiency and reliability of the PV power generation system, but also may cause safety risks such as fire, which poses a threat to the safe and reliable operation of the PV system. Therefore, timely and accurate diagnosis of PV inverter arc faults is crucial.

What are DC arc faults?

DC arc faults may occur due to aging, damage or poor contact of internal components of the inverter. Arc faults not only reduce the efficiency and reliability of the PV power generation system, but also may cause safety risks such as fire, which poses a threat to the safe and reliable operation of the PV system.

Can a DC arc flash a photovoltaic system?

It is unknown if that happens with a dc arc. Arc-flash on dc systems such as photovoltaic (PV) systems is relatively unknown. Several calculation approaches have been proposed, but these have not been backed by any industry tests on equipment and contradict one another.

Can an arc arc be detected through an inverter?

iring the ability to detect and terminate an arc through inverter shut down. The system has to remain shut down u til an installer has checked the site and repla ed any components if needed. Only then can the system be manually restarted.

Can DC arcs be used for arc fault detection?

Therefore, the random behavior of DC arcs can be used for arc fault detection. Due to its PWM control, the PV inverter emits high−frequency noise to the current during normal operation.

Why do photovoltaic inverters arc?

Photovoltaic inverters, as key devices, play an important role in converting DC energy to AC energy. However, arcing faults may occur due to aging, damage, or poor contact of components inside the inverter.

Guess what you want to know

-

DC inverter becomes smaller

DC inverter becomes smaller

-

5v DC to AC inverter

5v DC to AC inverter

-

Inverter DC component standard

Inverter DC component standard

-

DC inverter installation in Zimbabwe

DC inverter installation in Zimbabwe

-

Eritrea DC Solar PV Water Pump Inverter

Eritrea DC Solar PV Water Pump Inverter

-

How much does it cost to order a DC inverter

How much does it cost to order a DC inverter

-

The inverter output contains a DC component

The inverter output contains a DC component

-

24V Solar DC Inverter

24V Solar DC Inverter

-

The inverter reports that the DC component is too large

The inverter reports that the DC component is too large

-

DC screen inverter 220V

DC screen inverter 220V

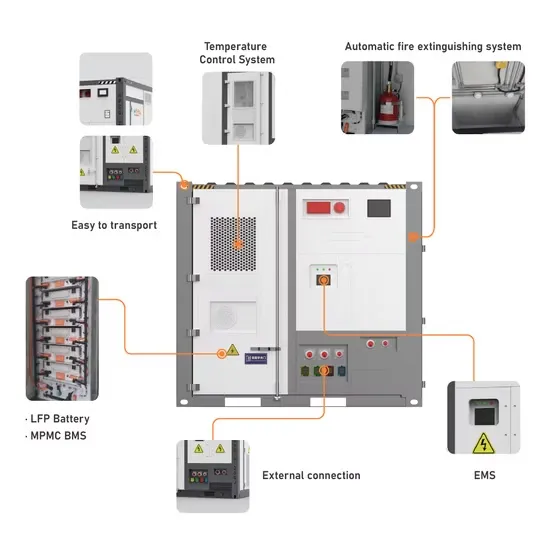

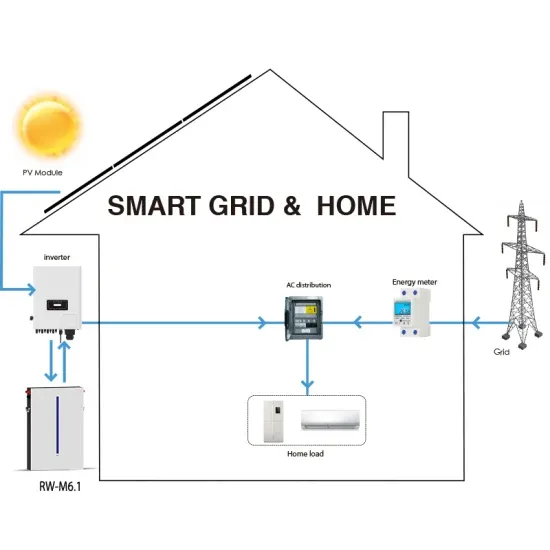

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.