Domestic flow battery Turkmenistan

Vanadium electrolyte alone contributes ~40% to a flow battery''''s costs, and we expect a vanadium battery installed in South Africa to easily achieve ~60% in local content with existing domestic

Get a quote

What is all-vanadium liquid flow battery energy storage?

The all-vanadium liquid flow battery represents a sophisticated and innovative approach to energy storage, characterized by its unique mechanism that utilizes vanadium

Get a quote

Rongke Power Completes World''s First Grid

The 200MW/1GWh vanadium flow battery system, built with the participation of Dalian Rongke Power Co., Ltd., marks a historic milestone —

Get a quote

Technical analysis of all-vanadium liquid flow batteries

Vanadium batteries are mainly composed of electrolyte, electrodes, selective proton exchange membranes, bipolar plates and fluid collectors. Among them, the electrolyte

Get a quote

Rongke Power

Welcome to Rongke Power. Discover our world-leading vanadium flow battery with unmatched efficiency, sustainability, and reliability. Explore key features and applications of

Get a quote

TURKMENISTAN VRB BATTERY

The Vanadium Redox Battery (VRB) is a type of rechargeable flow battery that employs vanadium ions in different oxidation states to store chemical potential energy. The vanadium redox

Get a quote

Turkmenistan liquid flow battery production enterprises

V-LIQUID in flow battery manufacturers in China has been engaged in the R&D and production of vanadium redox flow batteries since 2016, and the complete integration of

Get a quote

Vanadium batteries

The liquid with active substances is continuously circulated. The active material of vanadium liquid flow batteries is stored in liquid form in the external storage tank. The flow of

Get a quote

Turkmenistan liquid flow battery commercialization

Huo et al. demonstrate a vanadium-chromium redox flow battery that combines the merits of all-vanadium and iron-chromium redox flow batteries. The developed system with high theoretical

Get a quote

Advancing Flow Batteries: High Energy Density and

Energy storage is crucial in this effort, but adoption is hindered by current battery technologies due to low energy density, slow charging, and

Get a quote

Vanadium Redox Flow Batteries

Vanadium redox flow battery (VRFB) technology is a leading energy storage option. Although lithium-ion (Li-ion) still leads the industry in deployed capacity, VRFBs offer new capabilities

Get a quote

New All-Liquid Iron Flow Battery for Grid Energy Storage

New flow battery technologies are needed to help modernize the U.S. electric grid and provide a pathway for energy from renewable sources

Get a quote

Development status, challenges, and perspectives of key

Abstract All-vanadium redox flow batteries (VRFBs) have experienced rapid development and entered the commercialization stage in recent years due to the

Get a quote

Sichuan V-LiQuid Energy Co., Ltd.

We focus on the research, development, production, and sales of core materials, electric stacks, and integrated systems for all-vanadium flow batteries.

Get a quote

Ashgabat''s All-Vanadium Liquid Flow Energy Storage: Powering

Meet Ashgabat''s game-changing all-vanadium liquid flow energy storage system - the Clark Kent of energy solutions that''s been quietly revolutionizing how we store solar and wind power.

Get a quote

What you need to know about flow batteries

Exactly this old Vanadium RFB, at least its electrolyte is still in operation and according to our knowledge, has neglectable degradation after more than 30 years of operation. In general, the

Get a quote

Turkmenistan all-vanadium liquid flow battery

It adopts the all-vanadium liquid flow battery energy storage technology independently developed by the Dalian Institute of Chemical Physics. The project is expected to complete the grid

Get a quote

Sparton Resources Inc. VRB China Announcement

2 days ago· 200 Mega Watt Hour Project Successful BidTORONTO, Sept. 10, 2025 (GLOBE NEWSWIRE) -- Sparton Resources (TSX-SRI-V), ("the Company"), is pleased to report news

Get a quote

Vanadium redox flow batteries: a technology review

The vanadium redox flow batteries (VRFB) seem to have several advantages among the existing types of flow batteries as they use the same material (in liquid form) in both

Get a quote

What is all-vanadium liquid flow battery energy storage?

The all-vanadium liquid flow battery represents a sophisticated and innovative approach to energy storage, characterized by its unique

Get a quote

Vanadium Flow Batteries: Industry Growth & Potential

Explore the rise of vanadium flow batteries in energy storage, their advantages, and future potential as discussed by Vanitec CEO John Hilbert.

Get a quote

Introduction to Flow Batteries: Theory and Applications

The lifetime, limited by the battery stack components, is over 10,000 cycles for the vanadium flow battery. There is negligible loss of efficiency over its lifetime,

Get a quote

Technical analysis of all-vanadium liquid flow batteries

Vanadium battery principle and materials Vanadium batteries are mainly composed of electrolyte, electrodes, selective proton exchange membranes, bipolar plates

Get a quote

6 FAQs about [Turkmenistan vanadium liquid flow battery]

How can vanadium redox flow batteries increase their share in energy storage?

Overcoming the barriers related to high capital costs, new supply chains, and limited deployments will allow VRFBs to increase their share in the energy storage market. Guidehouse Insights has prepared this white paper, commissioned by Vanitec, to provide an overview of vanadium redox flow batteries (VRFBs) and their market drivers and barriers.

Will flow battery suppliers compete with metal alloy production to secure vanadium supply?

Traditionally, much of the global vanadium supply has been used to strengthen metal alloys such as steel. Because this vanadium application is still the leading driver for its production, it’s possible that flow battery suppliers will also have to compete with metal alloy production to secure vanadium supply.

Why are vanadium batteries so expensive?

Vanadium makes up a significantly higher percentage of the overall system cost compared with any single metal in other battery technologies and in addition to large fluctuations in price historically, its supply chain is less developed and can be more constrained than that of materials used in other battery technologies.

What happens if you use vanadium in a VRFB?

Its vanadium supply will then be used to produce electrolyte that can be provided to VRFB systems, essentially “erasing” the cost of vanadium from the total system cost. Because vanadium does not degrade after use in a VRFB, investors can maintain the value of their holdings.

How efficient are flow batteries compared to Li-ion batteries?

Flow batteries average between 70%-85% round-trip efficiency, compared with 90%-95% average for Li-ion batteries, potentially affecting the economics of projects based around bulk shifting of energy.

Are VRFBs a major source of new demand for vanadium?

Many stakeholders in the vanadium industry see VRFBs as a major source of new demand for the metal that has traditionally been used in steel alloys. This dynamic has resulted in government programs to support the technology’s development in China.

Guess what you want to know

-

Dominica s new vanadium titanium GW-grade all-vanadium liquid flow energy storage battery

Dominica s new vanadium titanium GW-grade all-vanadium liquid flow energy storage battery

-

Vanadium titanium all-vanadium liquid flow energy storage battery

Vanadium titanium all-vanadium liquid flow energy storage battery

-

Indonesia s new vanadium titanium GW-grade all-vanadium liquid flow energy storage battery

Indonesia s new vanadium titanium GW-grade all-vanadium liquid flow energy storage battery

-

Albania Vanadium Flow Battery Energy Storage Station

Albania Vanadium Flow Battery Energy Storage Station

-

Which type of vanadium is used in all-vanadium liquid flow batteries

Which type of vanadium is used in all-vanadium liquid flow batteries

-

Smart vanadium flow battery

Smart vanadium flow battery

-

Vanadium flow battery companies

Vanadium flow battery companies

-

Uzbekistan vanadium flow battery project

Uzbekistan vanadium flow battery project

-

Vanadium Flow Battery Trend

Vanadium Flow Battery Trend

-

Jamaica Vanadium Flow Battery Project

Jamaica Vanadium Flow Battery Project

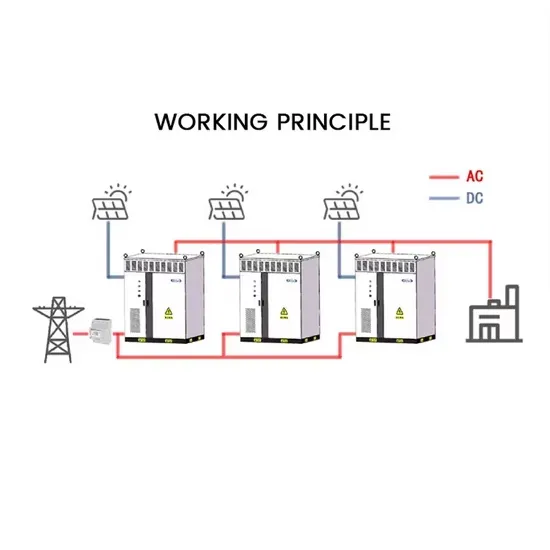

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.