Functions of BMS battery management system – DJDCPOWER

Overcurrent protection means that when the lithium battery supplies power to the load, the current will change with the change of voltage and power. When the current is large,

Get a quote

SOLVED: Is it Normal For BMS Voltage Reads Less

There was no smoke or anything when I plugged everything in, but the output voltage doesnt seem right. The top picture shows the output voltage of BMS,

Get a quote

What is a 4S Battery Management System? (What

4S BMS Charging Voltage A 4S BMS charging voltage is a type of battery management system that helps to ensure that your batteries are

Get a quote

Analysis of 12 common fault types of the battery management system (BMS)

With the rapid development of BMS technology, there are no alarms related to insulation detection. At the same time, it is rarely seen that the data of the acquisition module is 0.

Get a quote

SOLVED: Is it Normal For BMS Voltage Reads Less

I then connected B- lede of the BMS to the negative terminal of the battery pack and then plugged in the balancing wires to the BMS. However, when I

Get a quote

How Battery Management Systems (BMS) Prevent Battery

To maximize performance and safety, a Battery Management System (BMS) is a critical battery system component. The BMS monitors and manages various aspects of battery

Get a quote

BMS thinks it is dischaging when charging

First of all, if your charging current shows a negative number, it does not mean that it is continuously discharging. You need to check whether the cable you soldered is wrong, or

Get a quote

What Is a BMS and Why Does It Matter for LiFePO4?

In this regard, a BMS guarantees the battery is ready to deliver power safely during outages. The BMS keeps your battery in a safe condition. As a result, the battery

Get a quote

三代启动板 英文

DALY truck starting BMS is a software BMS specially developed and designed for starting trucks, ships, park ing air conditioners and truck starting power battery packs. It can withstand an

Get a quote

Understanding the Role of the BMS in Modern Lithium Batteries

The BMS tracks the voltage of each cell in the pack, ensuring they stay within safe limits. If one cell drifts too high or low, the BMS can cut off charging or discharging to protect the battery.

Get a quote

Analysis of common failures of BMS, an important partner of Li

If the BMS is not detected, this may lead to electric shock. Therefore, BMS systems have the highest requirements for monitoring sensors. Avoiding the failure of the monitoring system can

Get a quote

BMS Showing Negative Current when Charging and Positive

My BMS is showing Negative Current when Charging and Positive Current when Discharging. What could be causing that? Consequently, all functionality is reversed: AH is

Get a quote

BMS Showing Negative Current when Charging and Positive

My BMS is showing Negative Current when Charging and Positive Current when Discharging. What could be causing that? Consequently, all functionality is reversed: AH is growing when it

Get a quote

How Do I Know if My BMS is Bad? A Comprehensive Guide

Some of the signs of a bad BMS include irregular battery readings, the inability to charge the battery fully, or the battery discharging more quickly than usual. If you observe any of these

Get a quote

What is LiFePO4 Battery Management System (BMS)

Explore our guide to LiFePO4 Battery Management Systems (BMS) and learn why battery protection is essential for safety, longevity, and optimal performance.

Get a quote

Everything You Need to Know About Battery Balancing

With balancing, the Battery Management System (BMS) continuously monitors voltage differences and upper voltage limits. Once the preset voltage difference is reached, the

Get a quote

A Beginner''s Guide to Battery Management System

Summary A BMS is a complex system involving various terms and functions. From "1S" indicating series cells to "NMC" describing battery chemistry, and "MOSFET Count"

Get a quote

What Is A Battery Management System Sensor In A Car?

The BMS sensor offers crucial information about the battery''s current status, including its state of charge, temperature, and overall health. This data allows both the driver

Get a quote

The Complete Guide To A Battery Management System

However, its disadvantage is that it needs to manage multiple hardware units and communication networks, making system complex and costly.

Get a quote

Analysis of 12 common fault types of the battery

With the rapid development of BMS technology, there are no alarms related to insulation detection. At the same time, it is rarely seen that the data of the

Get a quote

SOLVED: Is it Normal For BMS Voltage Reads Less Than Battery

There was no smoke or anything when I plugged everything in, but the output voltage doesnt seem right. The top picture shows the output voltage of BMS, and the bottom shows the

Get a quote

Does a "normal" lithium battery BMS limit the current going into

There are many types of BMS (and many definitions of "normal"), but generally, in case of too high a charging current, a BMS will not limit the current to an acceptable level but

Get a quote

Analysis of common failures of BMS, an important

If the BMS is not detected, this may lead to electric shock. Therefore, BMS systems have the highest requirements for monitoring sensors. Avoiding the

Get a quote

What Does It Mean to Service Battery Charging System

Servicing a battery charging system means inspecting, maintaining, and repairing components that power your vehicle''s electrical systems. It ensures reliability and prevents

Get a quote

What Does It Mean If Your Battery Capacity Is Low

4 days ago· If your battery capacity is low, it means your device can''t hold as much charge as it once did. This reduces performance and runtime. But why does this happen, and can you fix

Get a quote

How to Test a BMS: A Step-by-Step Guide

Whether you''re building an e-bike battery, solar storage, or an EV pack, a malfunctioning BMS risks fires, poor performance, or costly replacements. By following these

Get a quote

6 FAQs about [What does it mean when the total current of the battery BMS is negative ]

Do lithium ion batteries need a BMS system?

Lithium-ion batteries, especially custom lithium ion battery packs, need a BMS (Battery Management System) to ensure the battery is reliable and safe. The battery management system is the brain of the lithium battery and reports the status and health of the battery. Let’s get a better understanding from this article. What is a BMS System?

How does a battery management system work?

The BMS tracks the voltage of each cell in the pack, ensuring they stay within safe limits. If one cell drifts too high or low, the BMS can cut off charging or discharging to protect the battery. 2. Cell Balancing During charging, cells can become unbalanced.

Does a 'normal' lithium battery BMS limit the current going into the battery?

Does a "normal" lithium battery BMS limit the current going into the battery when charging? If I hook up a 42 V voltage source with an absurd peak amperage to a 42 V battery through a BMS, will it protect the battery from too much current? Yes, but only by tripping, not limiting it. That assumes a real BMS with its own MOSFET (s).

Does BMS output match battery pack output?

However, when I measure the voltage across the BMS P- cable and the Battery Pack's positive terminal, I am only getting 47V even though the pack measures 58V. I read that the BMS output is supposed to match the pack output, but can't think of anything I did wrong.

What is a battery management system (BMS)?

BMS is an important accessory of Li-ion battery pack, it has a lot of functions, Li-ion battery management system BMS as a strong guarantee of safe battery operation, so that the battery maintains a safe and controlled charging and discharging process, greatly improving the cycle life of the battery in actual use.

What happens if a BMS is not detected?

If the BMS is not detected, this may lead to electric shock. Therefore, BMS systems have the highest requirements for monitoring sensors. Avoiding the failure of the monitoring system can greatly improve the safety of the power battery.

Guess what you want to know

-

What does BMS mean in battery

What does BMS mean in battery

-

What modules does the lithium battery BMS system have

What modules does the lithium battery BMS system have

-

What does 60 degrees mean for a battery cabinet

What does 60 degrees mean for a battery cabinet

-

What is the current of the energy storage battery

What is the current of the energy storage battery

-

What is the voltage and current of the energy storage cabinet battery

What is the voltage and current of the energy storage cabinet battery

-

What is the normal current of the battery in the energy storage cabinet

What is the normal current of the battery in the energy storage cabinet

-

What does the wattage of energy storage battery mean

What does the wattage of energy storage battery mean

-

What is the normal current of a 9v battery in an energy storage cabinet

What is the normal current of a 9v battery in an energy storage cabinet

-

What should the battery cabinet current be

What should the battery cabinet current be

-

What is a BMS battery cabinet

What is a BMS battery cabinet

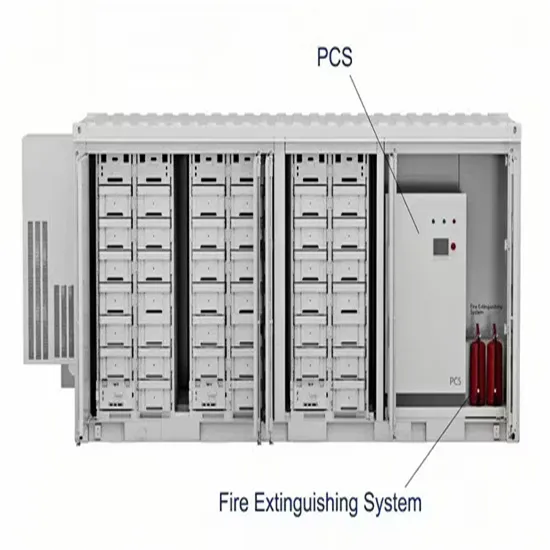

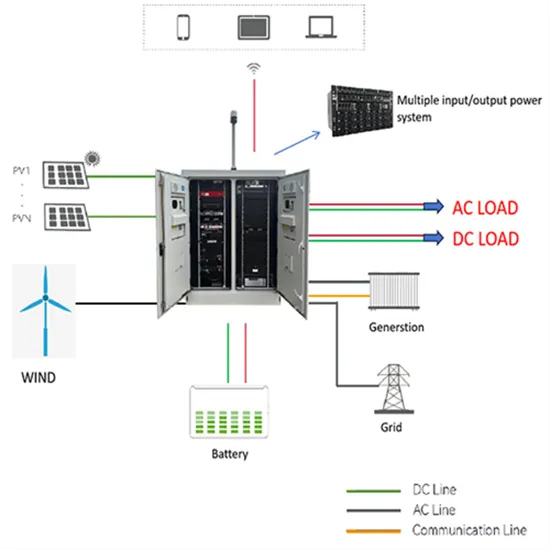

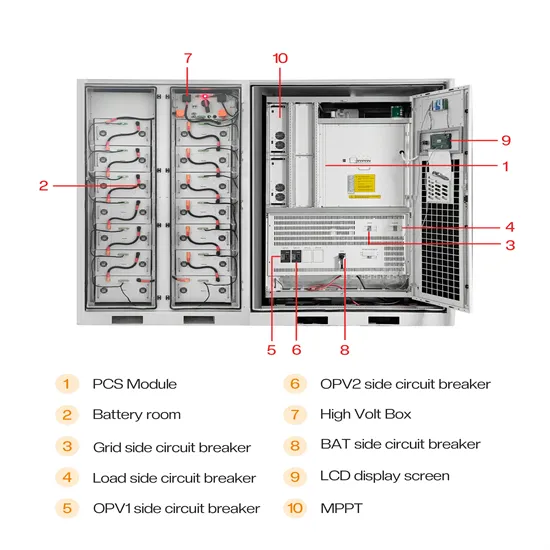

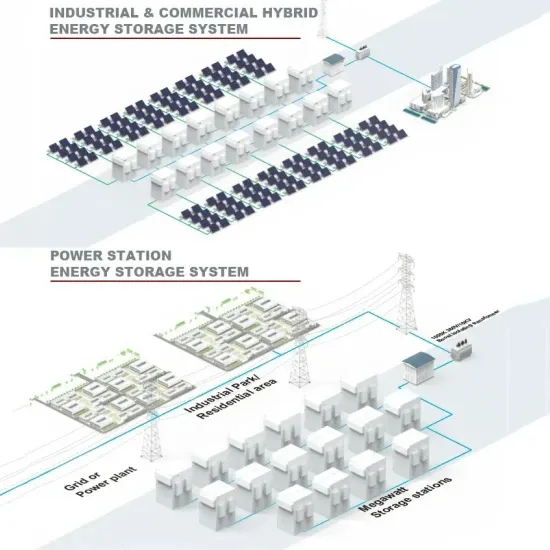

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.