Lithium Battery丨Battery Management System (BMS)

The BMS is made up of many components (sensor, control circuit, microcontroller, communication interface) that work together to control the

Get a quote

Battery Management System BMS for Lithium-Ion Battery Pack

In the lithium-ion battery pack, there are the main electronic modules: the batteries (cells) connected in groups in parallel and series, the cell contact system, and the BMS

Get a quote

What Is a BMS Battery and Why Need It | Grepow

A Battery Management System (BMS) is a critical electronic system integrated into rechargeable battery packs, especially lithium-ion batteries, to ensure their optimal

Get a quote

BMS for Lithium-Ion Batteries: The Essential Guide to Battery

Comprehensive guide to BMS for lithium-ion batteries. Learn battery management system functions, safety features, and protection mechanisms in 2025.

Get a quote

BMS module: What it is and why it is key in lithium batteries

Lithium batteries have revolutionized the world of portable power and energy storage, both in electronic devices and in electric vehicles and renewable energy systems.

Get a quote

How does lithium-ion BMS work? | Redway Battery (US)

Lithium-ion batteries have revolutionized the energy storage landscape, providing unmatched efficiency and longevity. Central to their performance is the Battery Management

Get a quote

What is a Battery Management System (BMS)?

A BMS offers more than simple protection circuit modules (PCMs). It provides complete management capabilities that help batteries last longer

Get a quote

Which BMS to select for a lithium battery?

The BMS "Battery Management System" is a term frequently used when talking about batteries, especially those using lithium technology. This electronic card is a

Get a quote

A Comprehensive Guide to 48V Lithium Battery BMS

Explore the vital role of 48V Lithium Battery BMS technology in optimizing battery performance for renewable energy systems, electric

Get a quote

What Is a Lithium Battery Management System and How Does It

LifePO4 batteries for the highest safety, performance, and reliability standards. A Lithium Battery Management System (BMS) monitors voltage, temperature, and current to

Get a quote

Lithium Battery丨Battery Management System (BMS) Explained

The BMS is made up of many components (sensor, control circuit, microcontroller, communication interface) that work together to control the battery''s performance.

Get a quote

How Do I Choose a BMS for a Lithium-Ion Battery?

Choosing the right Battery Management System (BMS) for a lithium-ion battery is crucial for ensuring safety, performance, and longevity. A BMS monitors and manages the

Get a quote

4 lithium battery safety factors | Factor 2: BMS

A Battery Management System, or BMS, is the "brains" of a lithium-ion battery Factor 2: Battery and BMS (Battery Management System) from Single Source Using a BMS

Get a quote

A Guide to Battery Energy Storage System

This is critical for the thermal management of the battery to help prevent thermal runaway. A well-designed BMS is a vital battery energy storage system

Get a quote

The Role of the BMS in Modern Lithium Batteries –

Every lithium battery relies on its BMS to monitor voltage, temperature, state of charge, and power distribution. If even one component

Get a quote

How does the battery management system (BMS) work in a lithium battery

Cell Monitoring: The BMS continuously monitors the voltage, temperature, and state of charge (SOC) of each individual cell in the battery pack. This allows it to detect any

Get a quote

The Role of Battery Management Systems (BMS) in Lithium and

Discover how a Battery Management System (BMS) improves the safety, lifespan, and performance of lithium and AGM batteries in South Africa. Learn more with Deltec Energy

Get a quote

Technical Deep Dive into Battery Management

A Battery Management System (BMS) is an electronic system designed to monitor, manage, and protect a rechargeable battery (or battery pack). It plays

Get a quote

The Role of the BMS in Modern Lithium Batteries – Why It Matters?

Every lithium battery relies on its BMS to monitor voltage, temperature, state of charge, and power distribution. If even one component fails, the battery may shut down or

Get a quote

How to Choose Basic or Smart BMS for Lithium Applications?

When designing a lithium battery system, one of the most important choices is whether to use a basic or smart Battery Management System (BMS). While both serve the core purpose of

Get a quote

What is a Battery Management System (BMS)? Essential Guide

A BMS offers more than simple protection circuit modules (PCMs). It provides complete management capabilities that help batteries last longer and prevent dangerous

Get a quote

Battery Cells vs. Modules vs. Packs: How to Tell the Difference

Learn the differences between battery cells, modules, and packs. See how each layer works, why BMS and thermal systems matter, and where these components fit in EVs and energy storage.

Get a quote

Analysis of 12 common fault types of the battery

BMS failures are relatively high and difficult to handle among all failures compared to other systems. The battery management system BMS (Battery

Get a quote

BMS module: What it is and why it is key in lithium batteries

There are three main types of BMS that are used in different applications depending on the specific needs of each system: Centralized BMS: A single controller

Get a quote

Battery Management System: Components, Types

Learn the basics of Battery Management Systems (BMS), improving battery performance, safety, and longevity in EVs, renewable energy, and more.

Get a quote

How does the battery management system (BMS) work in a

Cell Monitoring: The BMS continuously monitors the voltage, temperature, and state of charge (SOC) of each individual cell in the battery pack. This allows it to detect any

Get a quote

A Complete Guide to What is BMS for Lithium Ion Battery

A typical battery management system protection setting for lithium-ion batteries is BMS overcharge protection. A lithium battery''s overcharge protection will turn

Get a quote

6 FAQs about [What modules does the lithium battery BMS system have ]

What is a BMS for lithium-ion batteries?

A BMS for lithium-ion batteries acts as the "brain" of the battery pack, continuously monitoring, protecting, and optimizing performance to ensure safe operation and maximum lifespan. Understanding how BMS technology works is essential for anyone involved with lithium-ion applications.

What are the components of a lithium-ion battery pack?

In the lithium-ion battery pack, there are the main electronic modules: the batteries (cells) connected in groups in parallel and series, the cell contact system, and the BMS (battery management system). The BMS is the brain of the battery pack.

What is a battery management system (BMS)?

For electric vehicles, including electric cars, motorcycles, trucks, and boats, and modern solar energy systems, the safe and efficient operation of the batteries relies on a system/module -- battery management (BMS). The battery management system monitors the batteries' temperatures and voltages and manages the pack's status.

How does a lithium battery management system work?

Engineers working with lithium battery management systems need to understand cell balancing well. The BMS maintains charge balance between individual cells through active and passive methods. This substantially improves the battery’s lifespan and efficiency. A balanced system prevents degradation and maximizes capacity across the battery pack.

How to maintain a lithium battery – Battery Management System (BMS)?

Please keep the battery dry and clean, also avoid high temperature and do not overcharge or discharge. Lithium Battery丨Battery Management System (BMS) Explained Lithium batteries are very useful and many of the products we use every day are powered by them,like golf carts, power wheels, trolling motor, RV, etc.

What is a BMS in a battery pack?

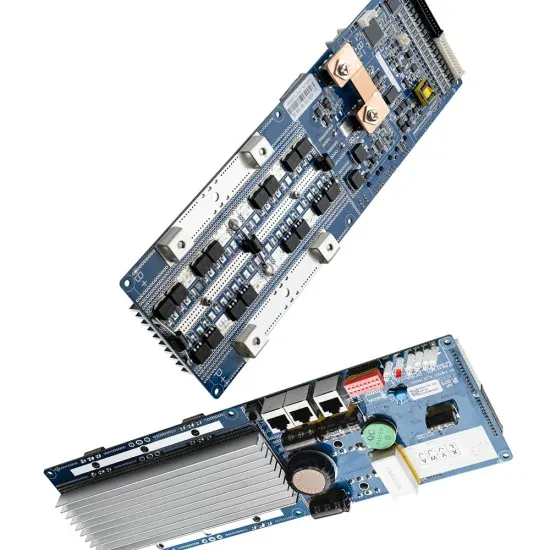

A BMS is a PCBA (printed circuit board assembly) in the battery pack. The main components mounted on the BMS printed circuit board include: Microcontroller (MCU): It gathers and processes current signals from the CCS to monitor the voltages and temperatures of the cells.

Guess what you want to know

-

Madagascar professional lithium battery bms merchant

Madagascar professional lithium battery bms merchant

-

New Zealand lithium battery bms wholesale

New Zealand lithium battery bms wholesale

-

Barbados lithium battery bms manufacturer

Barbados lithium battery bms manufacturer

-

Greek lithium battery bms function

Greek lithium battery bms function

-

Bulgaria lithium battery BMS solution

Bulgaria lithium battery BMS solution

-

What are the Japanese lithium battery station cabinet companies

What are the Japanese lithium battery station cabinet companies

-

Zimbabwe lithium battery BMS solution

Zimbabwe lithium battery BMS solution

-

How much does a BMS lithium battery cost in Niger

How much does a BMS lithium battery cost in Niger

-

What is an energy storage lithium battery

What is an energy storage lithium battery

-

Greek lithium battery bms wholesale

Greek lithium battery bms wholesale

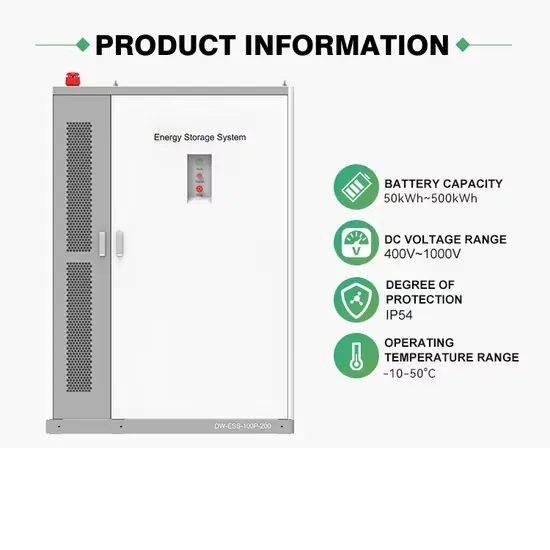

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.