Why Pre-Charge Circuits are Necessary in High-Voltage

Pre-charge circuits are often used in electric vehicles (EVs) such as battery management systems, on-board chargers, and in industrial applications such as power supplies and power

Get a quote

Energy Storage Pre-Charging: The Secret Sauce for Battery

Ever tried running a marathon without stretching? That''s exactly what happens when we skip energy storage pre-charging in battery systems. This crucial process acts like a yoga instructor

Get a quote

How Does a Battery Energy Storage System (BESS) Work?

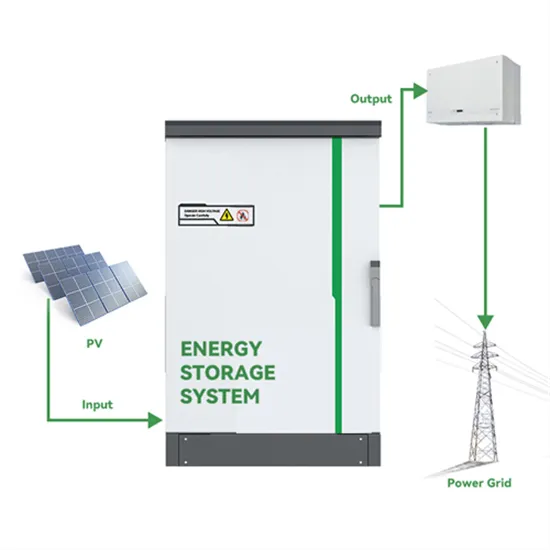

3 days ago· It''s energy shifting, resiliency, and ROI—all crammed into a steel cabinet. Here''s the basic loop: you charge the system when energy is cheap or overproduced (like noon on a

Get a quote

How does the energy storage cabinet charge? | NenPower

When it comes to energy storage cabinets, the charging process is an intricate interplay of technology and renewable energy management. At the heart of these cabinets lies

Get a quote

What does pre-charging new energy batteries mean

Pre-charging is when the battery is initially plugged in and is drawing a very small amount of current in order to get the chemical reaction started within the battery.

Get a quote

Sensata Precharge Circuit for Hybrid and Electric Vehicules

The total energy in the capacitor, the total energy dissipated by the resistor, and the total energy supplied by the battery all vary over time during precharging.

Get a quote

Choosing the Right Battery Storage Cabinet: A

Lithium-ion batteries have become indispensable across countless industries, from logistics and warehousing to construction and renewable

Get a quote

What Is an Energy Storage Battery Cluster? The Future of Power

Fun fact: The world''s largest battery cluster in California can power 300,000 homes for four hours. That''s like charging 15 million smartphones simultaneously!

Get a quote

Vertiv EnergyCore Battery System

EnergyCore Battery Cabinet The Vertiv EnergyCore is the first lithium-ion battery cabinet engineered specifically for data center use. Its compact design, proven safety features, and

Get a quote

Lithium Battery Charging Cabinet: The Essential Guide to Safe

A lithium battery charging cabinet is a secure enclosure designed specifically to store and charge lithium-ion batteries safely. Unlike standard cabinets, these feature

Get a quote

How Does a Battery Energy Storage System (BESS)

3 days ago· It''s energy shifting, resiliency, and ROI—all crammed into a steel cabinet. Here''s the basic loop: you charge the system when energy is cheap

Get a quote

Lithium-ion Storage Cabinets | DENIOS

A lithium-ion cabinet, also known as a battery charging cabinet or battery safety cabinet, is a special fireproof storage unit designed to charge and safely store

Get a quote

What Does the New Energy Storage Concept Mean? Let''s Break

The new energy storage concept acts like a high-yield savings account, letting us stash surplus energy during off-peak hours (like sunny afternoons or windy nights) and

Get a quote

Why Battery Energy Storage Station Pre-Charging is the Secret

In battery energy storage stations, pre-charging acts like a sophisticated "handshake" between components, gradually introducing current to prevent the equivalent of electrical whiplash.

Get a quote

What is pre-conditioning for electric cars and why should you do it?

Pre-conditioning uses the car''s batteries, or a direct supply of electricity if the EV is plugged in and charging. You simply select your desired temperature using the smartphone

Get a quote

What does the energy storage pre-charging circuit consist of?

Pre-charging protects not only the energy storage components but also various downstream systems that may be sensitive to sudden changes in load or voltage. The primary

Get a quote

What is preconditioning and how can it boost your

During the winter, the battery thus provides less energy and will lose its charge more quickly. Preconditioning warms the battery to optimum

Get a quote

What is a Battery Charging Cabinet? First time

In the UK alone, lithium ion battery charging cabinet demand has skyrocketed as fire services reported a staggering 93% increase in battery

Get a quote

CPUC Adopts New Rules Governing Safety of Battery Energy

On March 13, 2025, the California Public Utilities Commission (CPUC) modified General Order (GO) 167 to establish new standards for the maintenance and operation of battery energy

Get a quote

What does CCA mean on a battery: Everything you

In this article, we''ll dive deep into what does CCA mean on a battery, why it matters, what factors influence it, and how to choose the right battery based

Get a quote

New energy battery cabinet pre-charging time

The intelligent power exchange cabinet solves the problem of long battery charge turn-around time through battery sharing and battery exchange modes. It replaces the battery with a

Get a quote

Energy storage high voltage cabinet pre-charging circuit

More complex systems apply pre-charge as part of the starting sequence and will defer main contactor closure until the pre-charge voltage level is detected as sufficiently high.

Get a quote

What is EV Battery Pre-Conditioning?

What does pre-conditioning an EV battery do? In simple terms, pre-conditioning an EV battery means warming or cooling it before charging. This helps the

Get a quote

Preconditioning Your Tesla Battery: The Complete Guide

Preconditioning Your Tesla Battery: The Complete Guide Warming up your Tesla''s battery before setting off or plugging in doesn''t just prepare it for a

Get a quote

4 FAQs about [What does pre-charging a new energy battery cabinet mean ]

What is a pre-charge circuit?

High voltage (HV) positive and negative contactors are used in this system to act as an emergency disconnect when the motor regulator fails. Without a pre-charge circuit, welding can occur within the contactor as it closes and there could be a brief arc resulting in pitting. Figure 1. Pre-charge Initial State

What is a pre-charge initial state in a high voltage system?

Figure 1. Pre-charge Initial State In a high voltage system, a typical block diagram may consist of two high current contactors with a separate pre-charge contactor, and a DC link capacitor in parallel with a load (for example, traction inverter).

How does a pre-charge contactor work?

In the pre-charge state, the pre-charge contactor and the HV negative contactor are closed as shown in Figure 2. The DC link capacitor charges to nearly the same voltage as the voltage source. After the pre-charge state, the pre-charge contactor opens and the HV positive contactor closes to drive the system or charge the battery.

What is a pre-charge state?

Pre-charge State call the pre-charge state. In the pre-charge state, the pre-charge contactor and the HV negative contactor are closed as shown in Figure 2. The DC link capacitor charges to nearly the same voltage as the voltage source.

Guess what you want to know

-

What is a new energy battery cabinet photovoltaic

What is a new energy battery cabinet photovoltaic

-

What are the components of the new energy battery cabinet

What are the components of the new energy battery cabinet

-

What are the new energy battery cabinet brands

What are the new energy battery cabinet brands

-

What is the new energy battery cabinet motherboard

What is the new energy battery cabinet motherboard

-

What does the micro new energy battery cabinet contain

What does the micro new energy battery cabinet contain

-

Polish new energy battery cabinet replacement

Polish new energy battery cabinet replacement

-

What is the difference between an energy storage battery cabinet and a battery cabinet

What is the difference between an energy storage battery cabinet and a battery cabinet

-

What is the battery power of the energy storage cabinet in watts

What is the battery power of the energy storage cabinet in watts

-

Is the new energy battery cabinet charged How to connect it

Is the new energy battery cabinet charged How to connect it

-

What is the voltage of the new power battery cabinet

What is the voltage of the new power battery cabinet

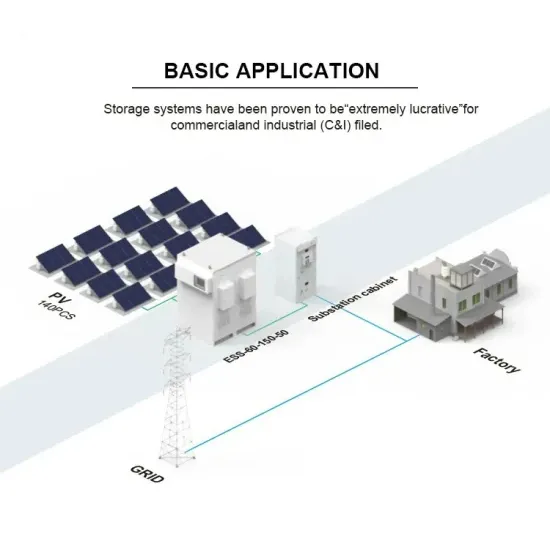

Industrial & Commercial Energy Storage Market Growth

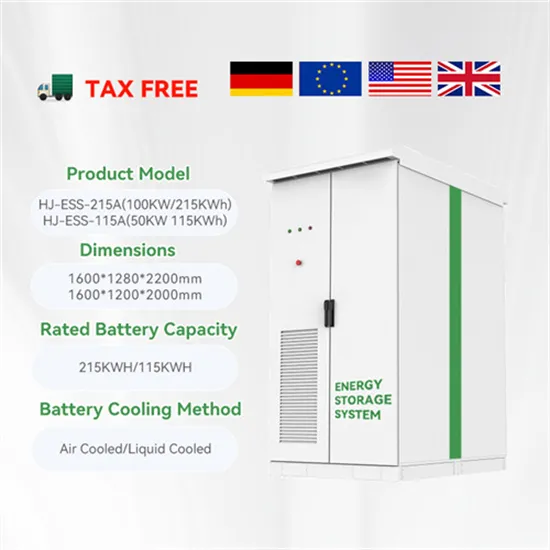

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.