Choosing the Right Wire Size for Your Solar Panel

Choosing the right solar panel system wiring is a critical yet frequently ignored consideration while designing a solar panel system. The

Get a quote

Solar Panel Thickness: What You Need to Know Before Buying

Learn how solar panel thickness impacts performance, durability, and cost. This article offers insights to help you make the best purchase decision.

Get a quote

We Analyzed 100 Solar Panels: Dimensions,

Solar panel depth, or thickness, is relatively consistent, generally ranging from 1.18 to 1.57 inches. Panels with a 1.38-inch (35 mm) depth are quite common.

Get a quote

We Analyzed 100 Solar Panels: Dimensions, Efficiency, & Load

Most solar panels fall within a length range of 67.8 to 93.9 inches and a width range of 39 to 51.3 inches. Lower wattage panels tend to be on the smaller end of these ranges, while higher

Get a quote

Material properties and thickness of each layer of PV

To determine how ambient temperature and wind speed affect PV module temperature, electrical efficiency, and electrical output under various

Get a quote

Design Guide for Bifacial Solar Modules

This Design Guide was created to aid in the understanding and optimization of Prism Solar''s PV modules. This document should be used as a supplement for individuals and system

Get a quote

What is the appropriate thickness of solar panels?

Choosing the right thickness for solar panels must take into account installation scenarios. Heavier and thicker panels require reinforced

Get a quote

Standard Specification for Thickness of Photovoltaic Panels in

But here''s the kicker - improper thickness selection caused $420M in structural damages last year alone. This article unpacks why photovoltaic panel thickness specifications are the unsung

Get a quote

Material properties and thickness of each layer of PV Panel [15].

To determine how ambient temperature and wind speed affect PV module temperature, electrical efficiency, and electrical output under various irradiance levels, a parametric study was

Get a quote

How Thick Are Solar Panels? [Updated: September 2025]

Are you interested in solar panels for your home but wondering how thick they are? You''re in the right place! In this article, we''ll discuss the typical thickness of a solar panel. We''ll

Get a quote

Solar Cable selection and Sizing for Solar Power Plant

Solar DC cable: Solar DC cables, also known as photovoltaic (PV) cables or solar panel cables, are specially designed electrical cables used in

Get a quote

Standard Solar Panel Sizes And Wattages (100W

To bridge that gap of very useful knowledge needed, we have compared and averaged the sizes of 100-watt to 500-watt solar panels available on the

Get a quote

What is the appropriate thickness of solar panels? | NenPower

Choosing the right thickness for solar panels must take into account installation scenarios. Heavier and thicker panels require reinforced mounting structures, which can lead

Get a quote

The Critical Role Of Solar Panel Backsheets:

Explore the essentials of solar panel backsheets: their functions, required certifications, structure, and types. Dive into understanding the best

Get a quote

Solar Panels: A Brief Guide on selecting the right one

Check out the different types of Solar panels and the factors to consider before buying a Solar Panel. that''s why we''ve laid out our guide to

Get a quote

Solar EVA Sheets for PV Cell Encapsulation | Targray

Targray Solar EVA sheets come in a range of sizes and types (resin, embossed), and are a trusted source for PV module manufacturers around the world.

Get a quote

How Solar Panel Thickness Affects Durability: What You Need to

Discover how solar panel thickness impacts durability and performance. Learn why thicker panels resist environmental stress better, withstand harsh conditions, and offer longer lifespans.

Get a quote

Solar Panel Thickness

Solar panels are a key component in solar power systems, and the thickness of the panels is an important factor in determining the overall efficiency of the system. The

Get a quote

The role of the backsheet for custom solar panel

1.1.1 The role of the backsheet for custom solar panel The back sheet is used for the rear surface of the custom solar panel and is one of the main

Get a quote

Standard Solar Panel Sizes And Wattages (100W-500W

To bridge that gap of very useful knowledge needed, we have compared and averaged the sizes of 100-watt to 500-watt solar panels available on the market. The goal here is to get to the

Get a quote

Solar Backsheets Unveiled: Understanding Types,

Uncover the intricacies of solar panel backsheets: from their core functions and vital certifications to their diverse types and structures. Learn

Get a quote

Solar Panel Thickness: What You Need to Know

Learn how solar panel thickness impacts performance, durability, and cost. This article offers insights to help you make the best purchase decision.

Get a quote

TECHNICAL SPECIFICATIONS OF ON-GRID SOLAR PV

The back sheet of PV module shall be minimum of three layers with outer layer (exposure to ambience) and shall be made of PVDF or PVF. The Back sheets for PV Module with 2 layered

Get a quote

Solar Cells: Size, Process and Technology Explained

Solar Cells: Size The core of photovoltaic solar panels solar cells, divided into monocrystalline solar cells and polycrystalline solar cells, because of

Get a quote

We Analyzed 100 Solar Panels: Dimensions, Efficiency, & Load

Solar panel depth, or thickness, is relatively consistent, generally ranging from 1.18 to 1.57 inches. Panels with a 1.38-inch (35 mm) depth are quite common. Some models, especially those

Get a quote

6 FAQs about [Selection of thickness of photovoltaic solar panels]

How thick is a solar panel?

The thickness of the glass on the panel is usually 3.2 mm, while the thickness of the aluminum frame is usually 30-40 mm. The thickness of the silicon solar cell is usually 100 micrometers, but it can range from 200 to 500 micrometers. The thickness of the glazing material on the panel can also affect the performance of the panel.

How thick are solar panels on satellites?

The thickness of solar panels on satellites can vary depending on the size and power output of the array. For example, state-of-the-art solar arrays for spacecraft providing up to 20 kW of electrical power typically consist of 3J solar cells bonded to hinged rigid panels that are around 1 inch in thickness.

How big are solar panels?

This is the typical classification of solar panel sizes (based on the solar cell size). It’s a bit theoretical and quite useless for most calculations. The only useful thing that we get from this is depth or height (panel thickness): Most solar panels are about 1.5 inches thick.

Why is it important to know the thickness of solar panels?

It’s important to know the thickness of your solar panels because it affects how much power they can generate. The thicker the panel, the more sunlight it can absorb, and the more power it can generate. So, if you’re looking to generate a lot of power with your solar panels, you’ll want to make sure they’re as thick as possible.

What size solar panel do I Need?

The most common solar panel size for homes is 65 inches by 39 inches. It’s important to know the thickness of your solar panels because it affects how much power they can generate. The thicker the panel, the more sunlight it can absorb, and the more power it can generate.

How deep is a solar panel?

The most common depth is 1.38 inches. Panel dimensions are influenced by wattage, cell technology, and panel design, which means sizes will always vary, even between panels with similar wattage or efficiency ratings. Understanding typical solar panel dimensions can help you plan your solar installation.

Guess what you want to know

-

Thickness of photovoltaic single-glass and double-glass solar panels

Thickness of photovoltaic single-glass and double-glass solar panels

-

What is the appropriate thickness of photovoltaic solar panels

What is the appropriate thickness of photovoltaic solar panels

-

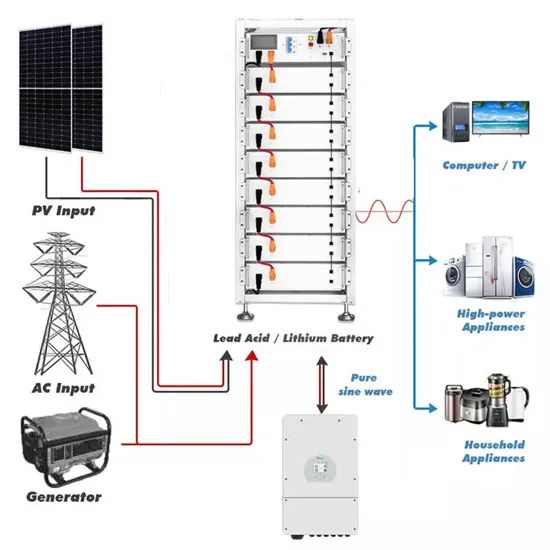

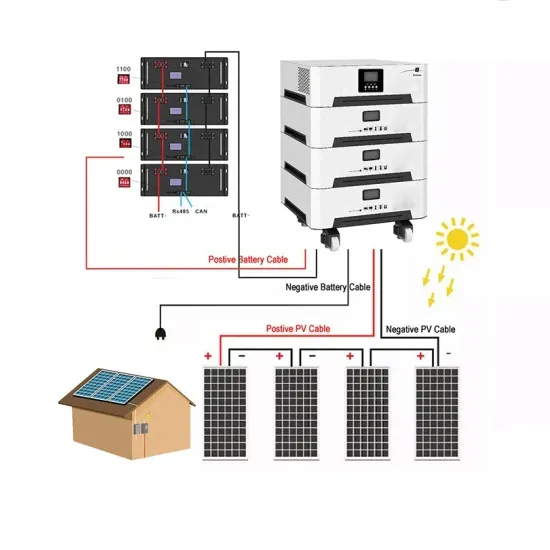

Solar panels with batteries and photovoltaic panels

Solar panels with batteries and photovoltaic panels

-

800w solar photovoltaic panels

800w solar photovoltaic panels

-

Company installation of photovoltaic solar panels

Company installation of photovoltaic solar panels

-

Can solar photovoltaic panels be used to pay for electricity

Can solar photovoltaic panels be used to pay for electricity

-

One-to-two photovoltaic panels solar integrated machine

One-to-two photovoltaic panels solar integrated machine

-

Georgia makes photovoltaic solar panels

Georgia makes photovoltaic solar panels

-

Photovoltaic solar panels for French homes

Photovoltaic solar panels for French homes

-

The most advanced photovoltaic solar panels currently

The most advanced photovoltaic solar panels currently

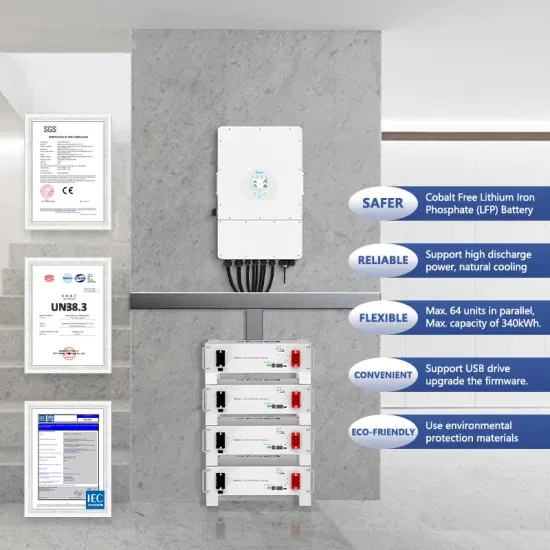

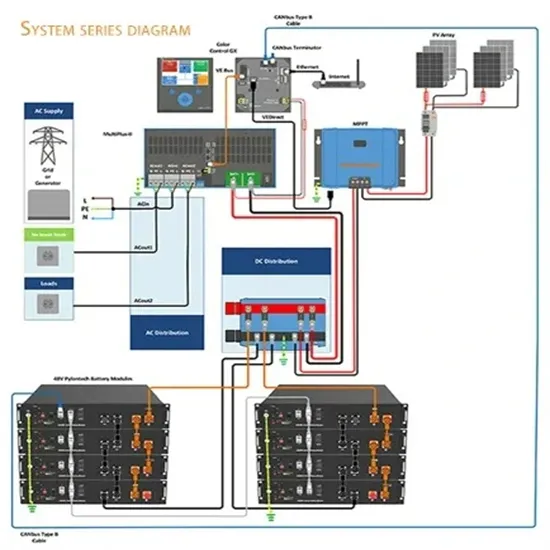

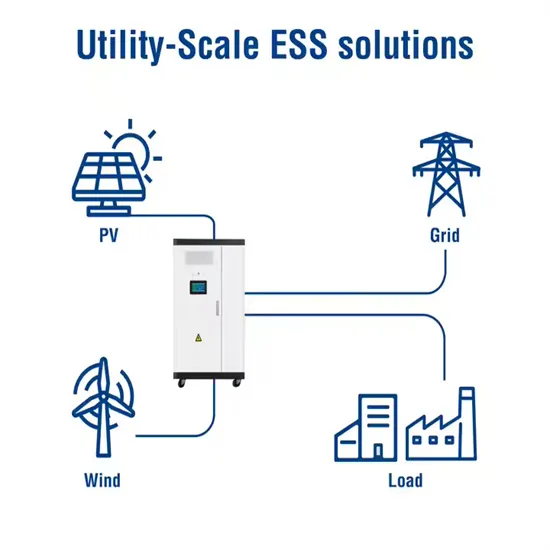

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.