Application of Permanent Magnet Synchronous Motor for

For EV motors, a widely frequency control method is deployed using a PWM input AC supply to the motor. However, controlling poles in conjunction with frequency controls has a potential in

Get a quote

Regenerative Battery Charging Control Method for

This paper illustrates regenerative battery charging control method of the permanent magnet synchronous motor (PMSM) drive without DC/DC

Get a quote

Development of electric vehicle with permanent magnet synchronous motor

New rare earth permanent magnet materials and advanced electronic controllers have made the traction motors more compact and energy efficient. EV motors combined with

Get a quote

Permanent Magnet Synchronous Generator 2000W

Buy Permanent Magnet Synchronous Generator 2000W 24V Brushless DC Low Rpm Alternator with Pure Copper Coil for Charging and Lighting Agricultural

Get a quote

(PDF) A Comprehensive Review on Electric Vehicle: Battery

Lithium-ion batteries are more efficient for EV applications, and boost converters and full bridge converters are commonly used in EVs. EVs use permanent magnet

Get a quote

Permanent Magnet Synchronous Motor

In this case, permanent magnet synchronous electric motors in comparison with other electric motors have the best performance: power/volume, torque/inertia, etc. Permanent magnet

Get a quote

Service life estimation of electric vehicle lithium-ion

The remaining useful life of the battery pack in the Permanent magnet synchronous motor drive is analyzed through mathematical modeling

Get a quote

Application of Permanent Magnet Synchronous Motor

Electric vehicles with use of permanent magnet synchronous motor, and brushless direct current motor [1] [2] requires high performance

Get a quote

Motenergy ME1507/1905

The ME1507 is an Radial Air Gap, Permanent Magnet Synchronous Motor (PMSM) with an Internal Permanent Magnet Rotor (IPM). Designed for battery pack voltages of 100 VDC or

Get a quote

Analysis and Simulation of Axial Flux Permanent

Due to the size of battery pack limitation, engine-propelled UAVs have become an appealing alternative as they possess high endurance (due

Get a quote

Cadillac Escalade IQ vs Lucid Gravity Test: Six-Figure Luxury EVs

Motors: 2 permanent-magnet synchronous AC, 750 hp, 785 lb-ft Battery Pack: liquid-cooled lithium-ion, 205 kWh Onboard Charger: 19.2 kW Peak DC Fast-Charge Rate:

Get a quote

Permanent Magnet Motor in Model 3 Tesla | Stanford

Due to the smaller body of the Model 3, even if a higher energy density 21700 lithium battery is used, the total energy is still lower than that of

Get a quote

A Comprehensive Review on Electric Vehicle: Battery

NMC Lithium nickel manganese cobalt oxide. SOC State of Charge. PI Proportional Integral. PMSM Permanent Magnet Synchronous Motor. PV SRM Photovoltaic. Switched Reluctance

Get a quote

Neodymium magnets and li-ion batteries in electric mobility

Neodymium magnets play a key role in Permanent Magnet Synchronous Motors (PMSM). In PMSM, neodymium magnets are placed on the motor rotor, generating a constant

Get a quote

Service life estimation of electric vehicle lithium-ion battery pack

The remaining useful life of the battery pack in the Permanent magnet synchronous motor drive is analyzed through mathematical modeling of the Lithium ion pack, three-phase

Get a quote

PMSM Motor for Electric Vehicles:

PMSM motor Permanent Magnet Synchronous Motor is a type of Permanent Magnet Motor widely used in Electric vehicles. PMSM motors are up to 15 percent more

Get a quote

Permanent Magnet Synchronous Generator for Offshore Wind

Abstract This paper describes modeling and control strategies of Permanent Magnet Synchronous Generators (PMSG) connected to lithium-ion battery pack to compensate intermittent energy

Get a quote

80V Electric Lithium-ionPneumatic Tire Forklift 4,000

The XE Series Electric Lithium-ion Pneumatic Forklift is a newly designed lithium-ion forklift from Hangcha Group. This dedicated lithium-ion powered forklift

Get a quote

Permanent Magnet Motor in Model 3 Tesla | Stanford Magnets

Due to the smaller body of the Model 3, even if a higher energy density 21700 lithium battery is used, the total energy is still lower than that of the Model S, and the battery

Get a quote

Deluxe EV 90Ah Lithium Battery 2025

1 day ago· The 3kW Permanent Magnet Synchronous Motor (PMSM) ensures smooth acceleration and consistent torque. It allows the scooter to reach speeds of up to 60 km/h,

Get a quote

Installation Design and Efficiency Evaluation of an EV

This study focuses on the transformation of Jaguar XJ40 vehicles to electric power, with the main equipment being a permanent-magnet

Get a quote

Installation Design and Efficiency Evaluation of an EV Transform

This study focuses on the transformation of Jaguar XJ40 vehicles to electric power, with the main equipment being a permanent-magnet synchronous motor (PMSM), lithium iron

Get a quote

(PDF) A Comprehensive Review on Electric Vehicle:

Lithium-ion batteries are more efficient for EV applications, and boost converters and full bridge converters are commonly used in EVs. EVs

Get a quote

PMSM Motor for Electric Vehicles:

PMSM use neodymium-iron-boron ("NdFeB") permanent magnets, which contain the rare earth elements neodymium, praseodymium, dysprosium and terbium. On average, a

Get a quote

Rotax E20 | ROTAX Racing

When BRP-Rotax created the E20, its developers poured all of their combined experience from years of active involvement in e-racing into its design. Rotax''s new e-unit gives you a next

Get a quote

Permanent Magnet Motor in Model 3 Tesla | Stanford

Model 3 uses permanent magnet motors to improve energy efficiency and extend battery life. Due to the smaller body of the Model 3, even

Get a quote

Different traction motor topologies with lithium-air battery for

Comparative analysis is carried out between various topologies. Moreover, we review the performance of different motor and battery combination that are available for

Get a quote

6 FAQs about [Permanent magnet synchronous motor and lithium battery pack]

What is a permanent magnet synchronous motor?

Permanent magnet synchronous motors are like BLDCM but use sinusoidal input power. Even though with a similar operating procedure wherein the stator windings offer a rotating magnetic field which allows the permanent magnet rotor to allow rotation at synchronous speed, it offers a smoother operation compared to BLDCM.

Which synchronous motors are used in electric vehicles?

PMSM Motors used in Electric Vehicles: Interior Permanent Magnet (IPM) synchronous motors possess special features for adjustable-speed operation. Motors with interior permanent magnet (IPM) rotors can provide exceptionally high efficiency. Permanent magnets are embedded within the rotor laminations internally fitted with a permanent magnet motor.

What is PMSM synchronous machine?

If the magnets are mounted on the surface of the rotor of the motor, the PMSM motor is called a Surface-mounted Permanent Magnet machine. If the magnets are mounted within the rotor, then the PMSM motor is called internally fitted with permanent magnets known as Interior Permanent Magnet (IPM) synchronous machine.

What is a PMSM motor?

PMSM motor Permanent Magnet Synchronous Motor is a type of Permanent Magnet Motor widely used in Electric vehicles. PMSM motors are up to 15 percent more efficient than Induction motors and are the most power-dense type of traction motors. The latest PMSM motors are being used in today’s Electric vehicles (EV) and Hybrid Electric Vehicles (HEV).

What are the advantages and disadvantages of permanent magnet synchronous motors?

Advantages: g ood reliability, high-speed performance, and low cost. Disadvantages: Low power density (larger volume at the same power level), low energy conversion efficiency, and high energy consumption. Permanent magnet synchronous motors are very similar in structure to AC asynchronous motors. The main components are also the stator and rotor.

How does a permanent magnet synchronous motor rotate?

The rotation of the permanent magnet synchronous motor is the magnetic field rotating on the stator attracts the constant magnetic field on the rotor, and the rotation speed of the stator magnetic field is consistent with the rotation speed of the rotor magnetic field.

Guess what you want to know

-

Lithium battery pack voltage halved

Lithium battery pack voltage halved

-

Kyrgyzstan energy storage lithium battery manufacturer system battery pack

Kyrgyzstan energy storage lithium battery manufacturer system battery pack

-

Pack lithium battery assembly price

Pack lithium battery assembly price

-

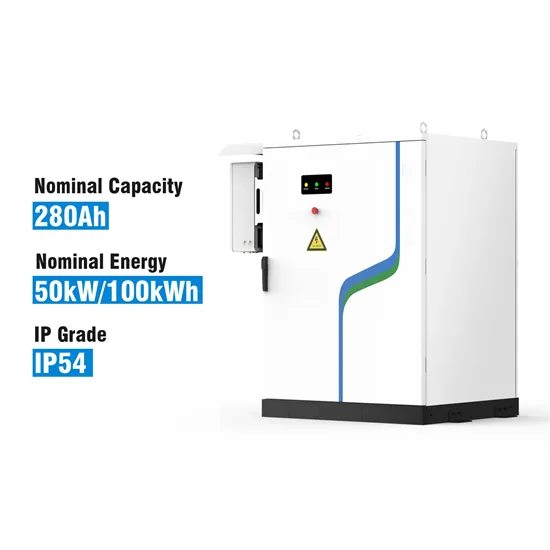

100kwh ultra-large capacity lithium battery pack

100kwh ultra-large capacity lithium battery pack

-

Introduction to Uzbekistan s solar lithium battery pack

Introduction to Uzbekistan s solar lithium battery pack

-

Cyprus lithium battery battery pack

Cyprus lithium battery battery pack

-

What brand of lithium battery pack do you use

What brand of lithium battery pack do you use

-

Which lithium battery pack is better in Nicaragua

Which lithium battery pack is better in Nicaragua

-

Lithium battery pack factory voltage

Lithium battery pack factory voltage

-

12v lithium battery pack output voltage

12v lithium battery pack output voltage

Industrial & Commercial Energy Storage Market Growth

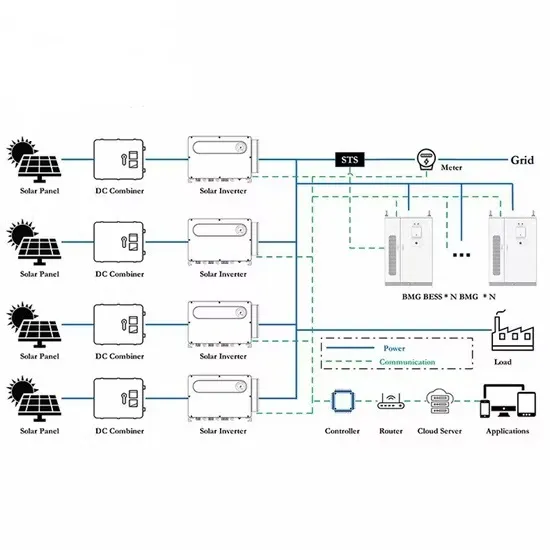

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.