A presentation on Daughter Booster stations, CNG

As the DB Stations are located in remote locations also, there is frequent events of power cut, voltage fluctuations which affects the availability of gas at CNG Stations. Engine Driven

Get a quote

What are the energy storage devices for photovoltaic booster

Why are energy storage technologies becoming a part of electrical power system? The reliability and efficiency enhancementof energy storage (ES) technologies,together with their cost are

Get a quote

How many meters are the distances between energy storage stations

Distances between energy storage stations range widely based on various factors, typically falling between 100 to 500 meters, local regulations, geographical considerations, and

Get a quote

How many meters are the distances between energy

Distances between energy storage stations range widely based on various factors, typically falling between 100 to 500 meters, local regulations,

Get a quote

Safety distance of energy storage power station

The first phase of the power station energy storage power and power generation installed capacity of 60 MW, energy storage capacity of 300 MW H, long-term construction scale of 1000 MW.

Get a quote

What is energy storage power station? | NenPower

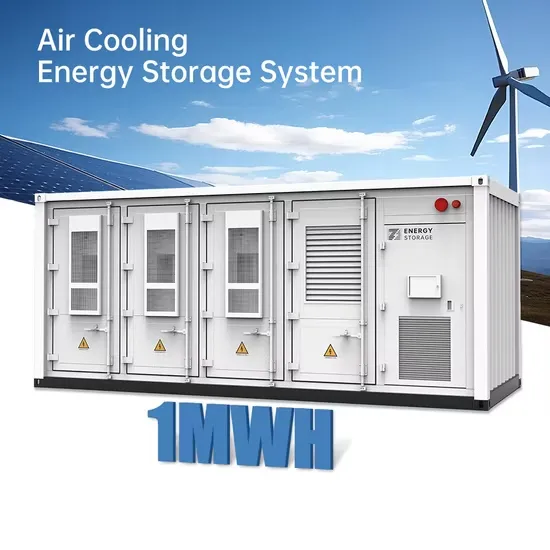

1. Energy storage power stations are critical infrastructure designed to store energy for later use, particularly from intermittent renewable

Get a quote

How does an energy storage booster station work?

When demand surges, energy storage booster stations discharge the stored energy onto the grid. This process is crucial for maintaining grid

Get a quote

Battery storage power station – a comprehensive guide

The guide covers the construction, operation, management, and functionalities of these power stations, including their contribution to grid stability, peak shaving, load shifting, and backup

Get a quote

Booster Stations and Energy Storage: Powering the Future Grid

Enter the game-changing partnership between booster stations and energy storage systems, the Batman and Robin of modern electricity networks. These technologies aren''t just buzzwords;

Get a quote

What are the differences between compressor

I think the compressor station is to compress the neutral gas into fuel gas for storage and transportation. The pumping station is transporting the

Get a quote

Daughter Booster Stations

Daughter Booster station CNG daughter booster station means CNG facilities not connected to natural gas pipeline and such CNG dispensing stations where mobile or stationary cascades

Get a quote

How far is the energy storage power station from the booster

The 100-megawatt to 200-megawatt-hour independent energy storage station developed by China Huaneng Group Co., Ltd. (China Huaneng) was connected to the power grid on Dec 29, 2021,

Get a quote

Battery storage power station – a comprehensive guide

The guide covers the construction, operation, management, and functionalities of these power stations, including their contribution to grid stability, peak

Get a quote

Distance between energy storage power station and booster station

For reducing the operation cost of shared energy storage stations and ensure the operation stability of power grid, this paper proposes an operation strategy of shared energy storage

Get a quote

How does an energy storage booster station work? | NenPower

When demand surges, energy storage booster stations discharge the stored energy onto the grid. This process is crucial for maintaining grid stability as it enables a swift

Get a quote

What is the optimal distance between energy storage stations?

The determination of the ideal spacing between energy storage stations is influenced by several distinct factors, including energy demand fluctuations, infrastructure

Get a quote

Capacity optimization strategy for gravity energy

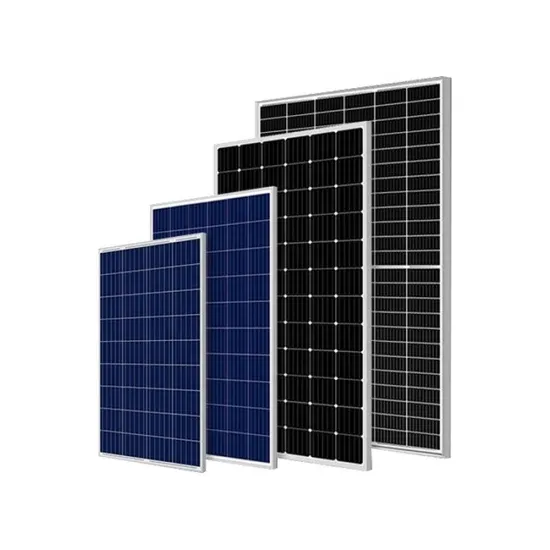

The integration of renewable energy sources, such as wind and solar power, into the grid is essential for achieving carbon peaking and

Get a quote

What is the optimal distance between energy storage

The determination of the ideal spacing between energy storage stations is influenced by several distinct factors, including energy demand

Get a quote

An Overview of Booster and Pressure Reducing Stations

Boost, Sustain or Reduce Pressure Custom Modular Pressure Control Stations Every Flowpoint pump station is custom-designed and engineered for your

Get a quote

Essential Safety Distances for Large-Scale Energy Storage

Discover the key safety distance requirements for large-scale energy storage power stations. Learn about safe layouts, fire protection measures, and optimal equipment

Get a quote

How far is the energy storage power station from the tower?

The distance between energy storage power stations and transmission towers is crucial. These towers serve as critical conduits for transmitting electricity across vast distances.

Get a quote

The 7 Best Portable Power Stations of 2025

Bring big backup power with you with these expert-recommended portable power stations, which can store enough power to charge electronics,

Get a quote

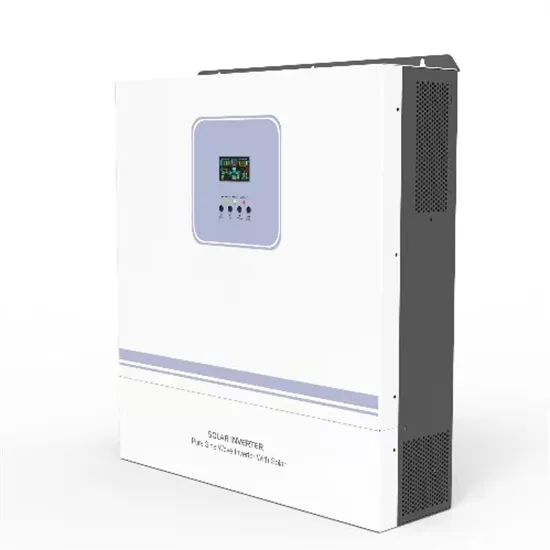

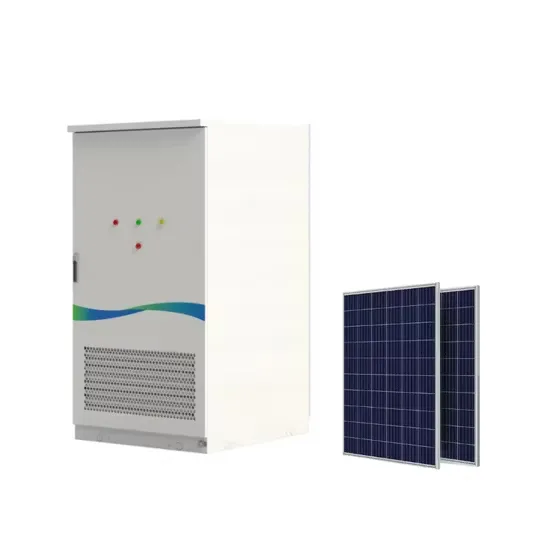

Energy storage booster station substation

The station microgrid technology provides a flexible and efficient platform for the integration of distributed generation and renewable energy power generation technology and its application

Get a quote

What are the Essential Site Requirements for Battery Energy Storage

Moreover, the spacing between battery units is also crucial for reducing the risk of fire spreading across the installation. Ensuring adequate ventilation and cooling is another key

Get a quote

Code Corner: NFPA 855 ESS Unit Spacing Limitations —

In Section 15.5 of NFPA 855, we learn that individual ESS units shall be separated from each other by a minimum of three feet unless smaller separation distances are

Get a quote

CNNC Huineng Energy Storage Power Station Project Initiated

The energy storage system will be connected to the nearby Pailing transformer after being boosted to 220kV by the booster converter integrated machine and 220kV main

Get a quote

Essential Safety Distances for Large-Scale Energy Storage Power Stations

Discover the key safety distance requirements for large-scale energy storage power stations. Learn about safe layouts, fire protection measures, and optimal equipment

Get a quote

What are the Essential Site Requirements for Battery Energy

Moreover, the spacing between battery units is also crucial for reducing the risk of fire spreading across the installation. Ensuring adequate ventilation and cooling is another key

Get a quote

6 FAQs about [Distance between energy storage power station and booster station]

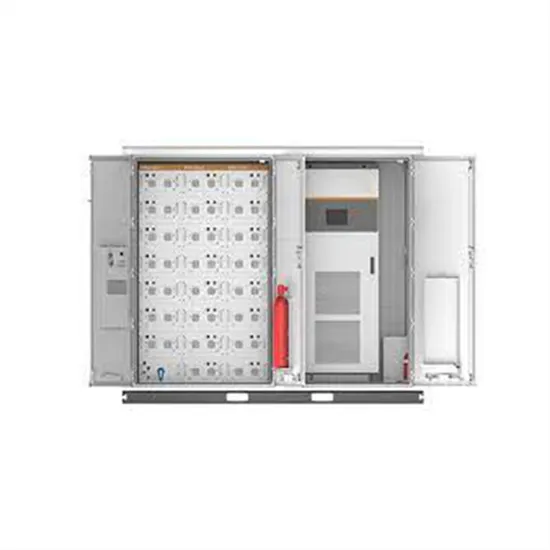

What are battery storage power stations?

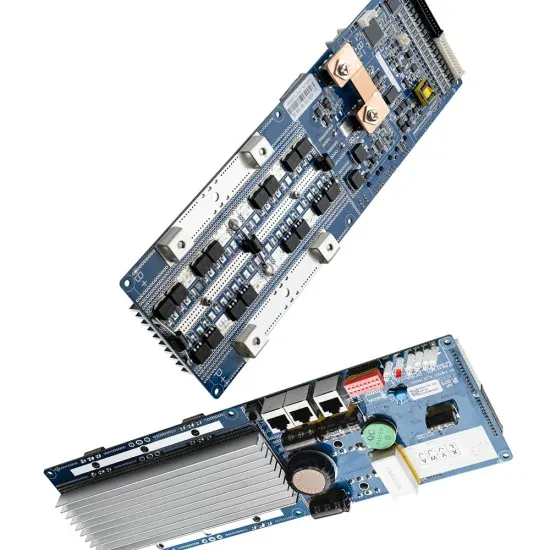

Battery storage power stations are usually composed of batteries, power conversion systems (inverters), control systems and monitoring equipment. There are a variety of battery types used, including lithium-ion, lead-acid, flow cell batteries, and others, depending on factors such as energy density, cycle life, and cost.

What is the construction process of energy storage power stations?

The construction process of energy storage power stations involves multiple key stages, each of which requires careful planning and execution to ensure smooth implementation.

How much energy can a ESS unit store?

Individual ESS units shall have a maximum stored energy of 20 kWh per NFPA Section 15.7. NFPA 855 clearly tells us each unit can be up to 20 kWh, but how much overall storage can you put in your installation? That depends on where you put it and is defined in Section 15.7.1 of NFPA 855.

Why do battery storage power stations need a data collection system?

Battery storage power stations require complete functions to ensure efficient operation and management. First, they need strong data collection capabilities to collect important information such as voltage, current, temperature, SOC, etc.

Are battery energy storage systems the future of grid stability?

Battery Energy Storage Systems represent the future of grid stability and energy efficiency. However, their successful implementation depends on the careful planning of key site requirements, such as regulatory compliance, fire safety, environmental impact, and system integration.

What is a battery energy storage system?

Telkes In recent years, Battery Energy Storage Systems (BESS) have become an essential part of the energy landscape. With a growing emphasis on renewable energy sources like solar and wind, BESS plays a crucial role in stabilizing the power grid and ensuring a reliable supply of electricity.

Guess what you want to know

-

Distance between energy storage power station containers

Distance between energy storage power station containers

-

Safety distance of distributed energy storage power station

Safety distance of distributed energy storage power station

-

Energy storage photovoltaic power station booster warehouse

Energy storage photovoltaic power station booster warehouse

-

Energy Storage Power Station Wind Power Market Booster Station

Energy Storage Power Station Wind Power Market Booster Station

-

Ground power station energy storage system

Ground power station energy storage system

-

Is energy storage power station a corporate investment

Is energy storage power station a corporate investment

-

Does Bangladesh s energy storage power station use vanadium batteries

Does Bangladesh s energy storage power station use vanadium batteries

-

What are the energy storage systems in the El Salvador power station

What are the energy storage systems in the El Salvador power station

-

South Sudan Chemical Energy Storage Power Station

South Sudan Chemical Energy Storage Power Station

-

Energy storage integrated photovoltaic power station

Energy storage integrated photovoltaic power station

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.