Air Cooling vs. Liquid Cooling of BESS: Which One Should You

In this blog, we will explore the differences between air cooling and liquid cooling in BESS, helping you make an informed decision based on your specific needs.

Get a quote

WHAT IS THE DIFFERENCE BETWEEN AIR COOLING AND LIQUID COOLING?

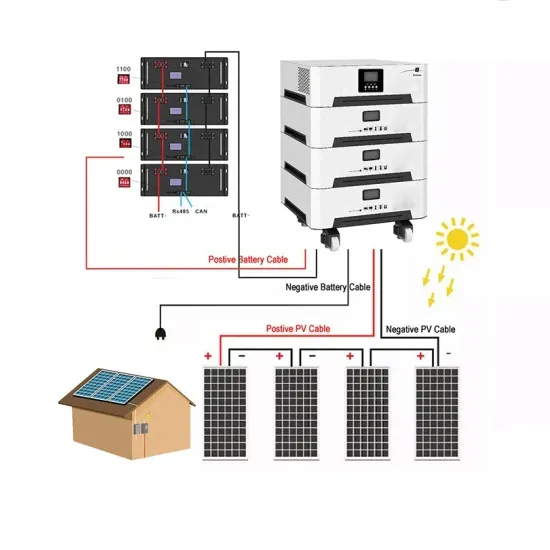

What is the energy storage liquid cooling system Liquid cooling systems in energy storage utilize a liquid coolant, typically water or specialized fluids, to effectively manage heat generated by

Get a quote

Eight major differences between air cooling and liquid cooling in

Air cooling and liquid cooling are two commonly used heat dissipation methods in energy storage systems, and they each have their own advantages and disadvantages.

Get a quote

Differences between liquid-cooled & air-cooled energy storage

The main differences between liquid-cooled energy storage systems and air-cooled energy storage systems are the heat dissipation methods and applicable scenarios. Liquid

Get a quote

The difference between air cooling and liquid cooling in energy storage

This video [The difference between air cooling and liquid cooling in energy storage Videos, The difference between air cooling and liquid cooling in energy storage Overview] has been shared

Get a quote

Eight differences between air cooling and liquid cooling in energy

The energy storage system is a key support for building a new power system. It can convert electrical energy into chemical energy for storage and release when needed. At present, air

Get a quote

Liquid vs. Air Cooling: Which One Should You Choose

Liquid cooling offers superior heat dissipation and efficiency for high-performance applications, while air cooling provides a cost-effective and simpler solution for moderate

Get a quote

Comprehensive Review of Liquid Air Energy Storage

In recent years, liquid air energy storage (LAES) has gained prominence as an alternative to existing large-scale electrical energy storage

Get a quote

What are the differences between Air Cooling, Cold Plate Liquid Cooling

What are the differences between air cooling, cold plate liquid cooling, and immersion liquid cooling? As the core component of an energy storage system, the battery cell is subject to

Get a quote

Eight Key Differences Between Air Cooling and Liquid Cooling in Energy

Currently, air cooling and liquid cooling are two widely used thermal management methods in energy storage systems. This article provides a detailed comparison of the differences

Get a quote

What are liquid cooling and air cooling systems in energy storage

Air Cooling in energy storage systems refers to using ambient air —often via fans or ductwork—to dissipate heat from battery cells. It relies on airflow to maintain safe

Get a quote

WHAT IS THE DIFFERENCE BETWEEN LIQUID COOLING AND AIR COOLING

What does the liquid cooling energy storage cabinet structure design service include To develop a liquid cooling system for energy storage, you need to follow a comprehensive process that

Get a quote

Air Cooling vs. Liquid Cooling: Why Liquid Cooling is the Future of

With its superior thermal performance, enhanced energy efficiency, and improved battery longevity, liquid cooling is rapidly becoming the preferred solution for commercial &

Get a quote

Difference Between Liquid and Air Cooling for Energy Storage

Discover the key differences between liquid and air cooling for energy storage systems. Learn how each method impacts battery performance, efficiency, and lifespan to

Get a quote

Battery Storage Cooling Methods: Air vs Liquid Cooling

9 hours ago· As battery energy storage systems grow in scale, thermal management becomes a defining factor for performance, safety, and lifespan. While people often focus on cell

Get a quote

Eight Key Differences Between Air Cooling and Liquid

Air cooling and liquid cooling are two commonly used cooling methods in energy storage systems. Below is a detailed comparison of their

Get a quote

Air-Cooled vs. Liquid-Cooled Energy Storage Systems: Which Cooling

Both air-cooled and liquid-cooled energy storage systems (ESS) are widely adopted across commercial, industrial, and utility-scale applications. But their performance,

Get a quote

What are liquid cooling and air cooling systems in energy storage

Discover the differences between air and liquid cooling for energy storage packs—covering their pros, cons, applications, and selection criteria. Learn how Huiyao Laser

Get a quote

Air-Cooled vs. Liquid-Cooled Energy Storage Systems: Which

Both air-cooled and liquid-cooled energy storage systems (ESS) are widely adopted across commercial, industrial, and utility-scale applications. But their performance,

Get a quote

Eight Key Differences Between Air Cooling and Liquid

Currently, air cooling and liquid cooling are two widely used thermal management methods in energy storage systems. This article provides a detailed

Get a quote

Air Cooling vs. Liquid Cooling: Why Liquid Cooling is

With its superior thermal performance, enhanced energy efficiency, and improved battery longevity, liquid cooling is rapidly becoming the

Get a quote

CON371 CH4 Flashcards | Quizlet

Study with Quizlet and memorize flashcards containing terms like How do the vapor compression and the absorption cycle differ in their methods of condensing refrigerant?, What is the

Get a quote

Differences between liquid-cooled & air-cooled energy storage

High power, high energy density, and strict temperature control requirements: liquid cooling is more advantageous. Low power, cost-sensitive, and high safety requirements: air

Get a quote

Comparison of cooling methods for lithium ion battery

Comparison of cooling methods for lithium ion battery pack heat dissipation: air cooling vs. liquid cooling vs. phase change material cooling vs.

Get a quote

Liquid Cooling VS Air Cooling in Data Centres

Explore the differences liquid cooling vs air cooling in data centres, focusing on efficiency, energy consumption, and why liquid cooling is the future.

Get a quote

Difference Between Liquid and Air Cooling for Energy

Discover the key differences between liquid and air cooling for energy storage systems. Learn how each method impacts battery

Get a quote

The difference between energy storage liquid cooling system

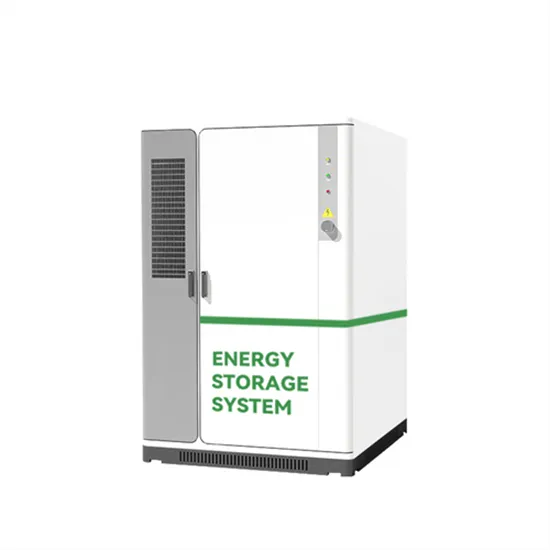

Air and liquid cooling systems for Energy Storage Systems (ESS) differ in thermal conductivity,maintenance needs,and overall efficiency. Air cooling relies on fans to circulate air

Get a quote

Commercial Energy Storage: Liquid Cooling vs Air Cooling

Liquid cooling, by contrast, utilities circulating coolant to absorb and transfer heat away from critical components. This technology shines in high-energy density applications,

Get a quote

6 FAQs about [The difference between liquid cooling and air cooling energy storage]

What is the difference between air cooling and liquid cooling?

Air cooling offers simplicity, cost-effectiveness, and reliability, making it suitable for smaller or less demanding applications. Liquid cooling, with its superior efficiency, compact design, and quieter operation, is better suited for high-capacity or high-performance systems.

Why are liquid cooling systems more expensive than air cooling systems?

Higher Costs: The installation and maintenance of liquid cooling systems can be more expensive than air cooling systems due to the complexity of the system and the need for specialized components. Potential for Leaks: Liquid cooling systems involve the circulation of coolant, which introduces the risk of leaks.

Are liquid cooling systems more compact than air cooling systems?

Compact Design: Liquid cooling systems are typically more compact than air cooling systems, as they don’t require as much space for airflow. This can be a crucial factor in installations where space is limited.

What is liquid cooling & how does it work?

Liquid cooling, on the other hand, uses a coolant fluid to absorb and dissipate heat from the batteries. This method is becoming increasingly popular, especially in large-scale or high-performance BESS applications.

What is the difference between free cooling and liquid cooled technology?

The free cooling technology consists of using the natural fluid to cool data centers. The liquid cooled technology is useful when the data centers have a high-power density. The two-phase flow technology consists of using a refrigerant capable of removing dissipated heat by racks and rejecting to the outside environment.

Which cooling method is best for battery energy storage systems?

When it comes to managing the thermal regulation of Battery Energy Storage Systems (BESS), the debate often centers around two primary cooling methods: air cooling and liquid cooling. Each method has its own strengths and weaknesses, making the choice between the two a critical decision for anyone involved in energy storage solutions.

Guess what you want to know

-

What are liquid cooling and air cooling for energy storage cabinets

What are liquid cooling and air cooling for energy storage cabinets

-

Advantages and disadvantages of air cooling and liquid cooling for energy storage

Advantages and disadvantages of air cooling and liquid cooling for energy storage

-

Which is better for energy storage cabinets air cooling or liquid cooling

Which is better for energy storage cabinets air cooling or liquid cooling

-

Comparison of liquid cooling and air cooling for energy storage

Comparison of liquid cooling and air cooling for energy storage

-

The difference between energy storage liquid cooling system and full liquid cooling

The difference between energy storage liquid cooling system and full liquid cooling

-

Serbia Liquid Cooling Energy Storage Management Company

Serbia Liquid Cooling Energy Storage Management Company

-

Liquid Cooling Energy Storage Container Prices in South America

Liquid Cooling Energy Storage Container Prices in South America

-

Industrial and commercial integrated energy storage liquid cooling

Industrial and commercial integrated energy storage liquid cooling

-

Nigeria Liquid Cooling Energy Storage Operation Company

Nigeria Liquid Cooling Energy Storage Operation Company

-

Cambodia liquid cooling energy storage company

Cambodia liquid cooling energy storage company

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.