Complete turnkey lines for pv panel production

Discover our complete turnkey lines for photovoltaic panel production. From start to finish, state-of-the-art lines designed for Solar Panels.

Get a quote

Complete turnkey lines for pv panel production

Discover our complete turnkey lines for photovoltaic panel production. From start to finish, state-of-the-art lines designed for Solar Panels.

Get a quote

Solar Photovoltaic Manufacturing Basics

Solar manufacturing encompasses the production of products and materials across the solar value chain. This page provides background information on

Get a quote

How to Start a Solar Panel Manufacturing Plant:

Solar Panel Manufacturing Plant Complete Guide is your go-to resource for diving into the world of solar panel production. This guide will take you through every

Get a quote

PV Solar Cell Manufacturing Process & Equipment

Explore the solar module manufacturing process in detail and discover how Smartech''s solutions enhance efficiency in PV cell production.

Get a quote

Solar panel production line

Our solar panel manufacturing plants are equipped with the latest in photovoltaic panel machinery and solar-making machines These facilities support large

Get a quote

Solar Panel Manufacturing Challenges

Solar energy is booming, and solar panel manufacturing is at the heart of this revolution. In this article, we''ll explore how solar panels are made

Get a quote

Specialist in Solar Panel Manufacturing Equipment | Horad

Horad is a specialist in solar panel manufacturing equipment. Our company is committed to providing efficient turnkey lines and a range of individual equipment for customers from around

Get a quote

Solar Panel Manufacturing

Custom-designed solutions tailored to the specific needs of solar panel manufacturers. Proven track record in helping manufacturers achieve higher efficiency, lower costs, and regulatory

Get a quote

Top 11 Solar Panel Manufacturers in China : 2025 Industry Guide

Explore top solar panel manufacturers in China, production centers, and decisions on sourcing the best solar panels made in china.

Get a quote

Solar Karya Indonesia – Renewable Energy For A

Our products are widely used in a wide range of solar panel applications, power range from 1 W – 700 W. In 2024 we have produced more than 100K solar

Get a quote

SOLAR/PV EQUIPMENT – Semiphoton

Our automated Solar/PV modules production line includes a complete set of equipment, such as solar cells laser cutting, string soldering, welding, glass loading, layup,

Get a quote

Welcome to centrotherm | centrotherm

Production solutions for wafer manufacturing, power semiconductors, MEMS, optoelectronics, passive components and advanced packaging. Integrated production solutions and process

Get a quote

Solar Panel Life Cycle Assessment: Making PV

The life cycle of solar panels represents a critical framework for evaluating the true environmental impact of photovoltaic technology, from raw

Get a quote

Solar panel production line

Our solar panel manufacturing plants are equipped with the latest in photovoltaic panel machinery and solar-making machines These facilities support large-scale production capacities from

Get a quote

Solar Panel Manufacturing Unit

Find here Solar Panel Manufacturing Unit, Solar Panel Manufacturing Plant manufacturers, suppliers & exporters in India. Get contact details & address of

Get a quote

Photovoltaic panel semi-finished product packaging

Photovoltaic panel semi-finished product packaging How do I choose the best solar panel packaging? Consider the following factors when choosing solar panel packaging:

Get a quote

What is polysilicon and how is it made? — RatedPower

What is polysilicon? Polysilicon definition: Polycrystalline silicon, commonly shortened to polysilicon, is a purified form of silicon that includes p-type and n-type

Get a quote

SOLAR/PV EQUIPMENT – Semiphoton

Our automated Solar/PV modules production line includes a complete set of equipment, such as solar cells laser cutting, string soldering, welding, glass loading, layup, laminating, framing, J

Get a quote

Innovators of Solar Components | Commitment to

To become one of India''s largest solar panel glass manufacturers, we have established the country''s largest greenfield solar glass manufacturing plant at

Get a quote

Semi-Finished Solar Products Processing

Flexibility and Adaptability: Shaped solar panels can be custom-designed to fit different shapes and surfaces, allowing for better utilisation of available space

Get a quote

Semi-Finished Solar Products Processing Manufacturing Small

Flexibility and Adaptability: Shaped solar panels can be custom-designed to fit different shapes and surfaces, allowing for better utilisation of available space and adapting to complex

Get a quote

Solar Photovoltaic Manufacturing Basics

Solar manufacturing encompasses the production of products and materials across the solar value chain. This page provides background information on several manufacturing processes

Get a quote

Production of crystalline silicon modules | AVENSTON

Article reviews the technology of solar modules based on silicon photovoltaic cells. Briefly considered a standard process that is used with

Get a quote

Solar Panel Manufacturing Process: Step-by-Step Guide

Complete solar panel manufacturing process – from raw materials to a fully functional solar panel. Learn how solar panels are made in a solar manufacturing plant,

Get a quote

PV Solar Cell Manufacturing Process & Equipment Explained

Explore the solar module manufacturing process in detail and discover how Smartech''s solutions enhance efficiency in PV cell production.

Get a quote

6 FAQs about [Photovoltaic panel semi-finished product processing manufacturers]

What is a photovoltaic (PV) solar cell?

Central to this solar revolution are Photovoltaic (PV) solar cells, experiencing a meteoric rise in both demand and importance. For professionals in the field, a deep understanding of the manufacturing process of these cells is more than just theoretical knowledge.

How are solar modules manufactured?

Assembly and Testing: The cells are assembled into modules and undergo thorough testing for efficiency and durability, ensuring they meet the high standards required for solar energy applications. Solar photovoltaic lamination stands as an important step in the solar module manufacturing process.

How are PV solar cells made?

The manufacturing process of PV solar cells necessitates specialized equipment, each contributing significantly to the final product’s quality and efficiency: Silicon Ingot and Wafer Manufacturing Tools: These transform raw silicon into crystalline ingots and then slice them into thin wafers, forming the substrate of the solar cells.

What is solar photovoltaic lamination?

Solar Photovoltaic Lamination: In this critical phase, the cells are encapsulated within laminated glass or other protective materials. This solar module lamination not only protects the cells from environmental factors but also enhances their overall performance and longevity.

Do you offer a complete set of PV machines?

We offer a complete set of PV machines covering all solar manufacturing processes. We offer complete solar panel production lines for global customers to manufacture photovoltaic modules based on their specific requirements.

What is a solar PV supply chain?

Those systems are comprised of PV modules, racking and wiring, power electronics, and system monitoring devices, all of which are manufactured. Learn how PV works. Read the Solar Photovoltaics Supply Chain Review, which explores the global solar PV supply chain and opportunities for developing U.S. manufacturing capacity.

Guess what you want to know

-

African photovoltaic panel processing manufacturers

African photovoltaic panel processing manufacturers

-

Are there any photovoltaic panel manufacturers in Uzbekistan

Are there any photovoltaic panel manufacturers in Uzbekistan

-

Russia develops photovoltaic panel manufacturers

Russia develops photovoltaic panel manufacturers

-

Suriname rural photovoltaic panel manufacturers

Suriname rural photovoltaic panel manufacturers

-

How many photovoltaic panel manufacturers are there in Rwanda

How many photovoltaic panel manufacturers are there in Rwanda

-

Canadian grid-connected photovoltaic panel manufacturers

Canadian grid-connected photovoltaic panel manufacturers

-

West African photovoltaic panel manufacturers prices

West African photovoltaic panel manufacturers prices

-

Are there photovoltaic panel manufacturers in Venezuela

Are there photovoltaic panel manufacturers in Venezuela

-

Norway solar panel wholesale processing photovoltaic roof BESS

Norway solar panel wholesale processing photovoltaic roof BESS

-

Photovoltaic insulation solar panel manufacturers

Photovoltaic insulation solar panel manufacturers

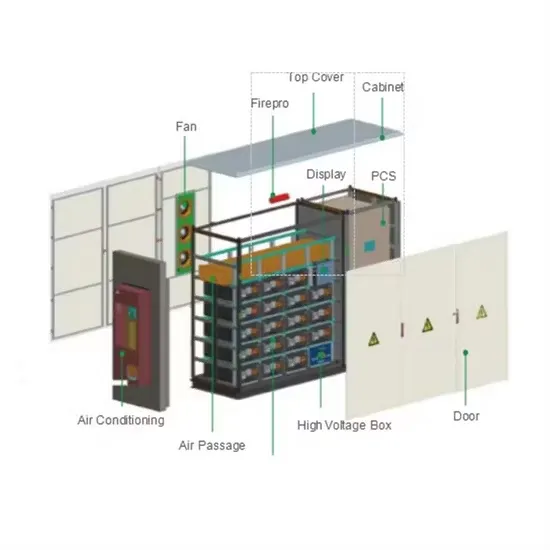

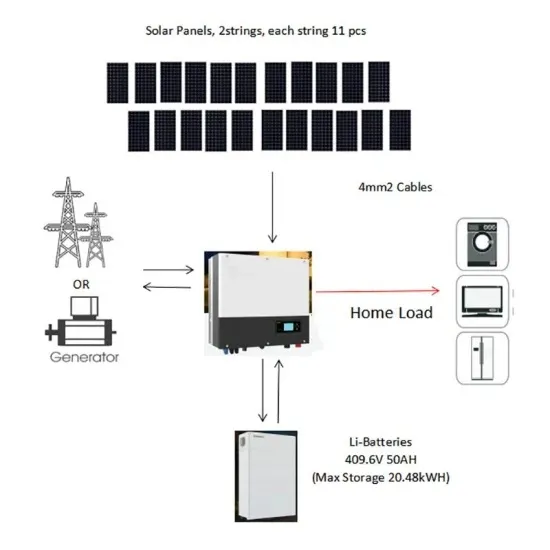

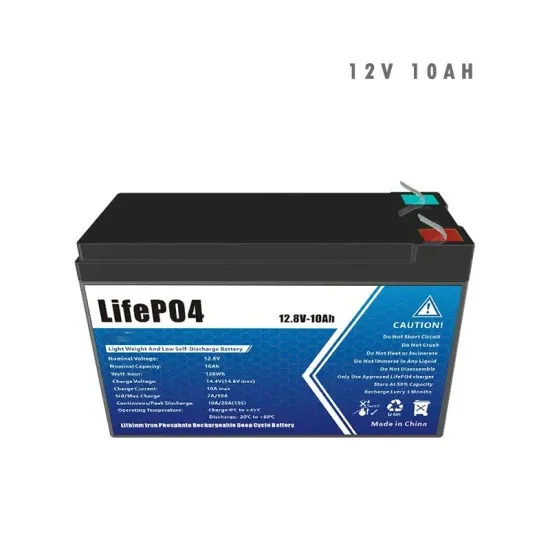

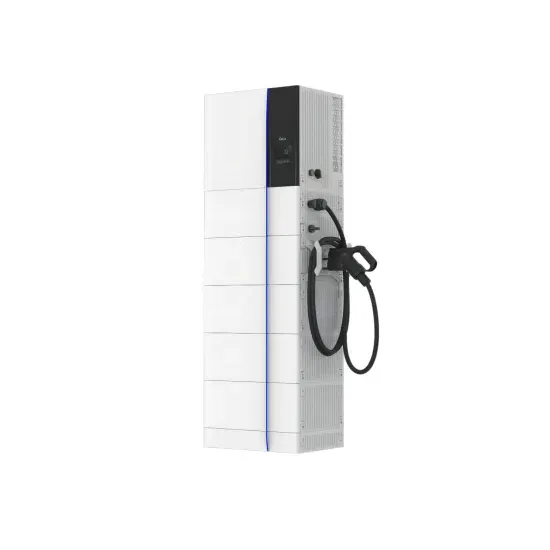

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.