Battery to inverter: Different wire gauge used

I have 2 48V 100AH batteries (EG4-LL) connected to my inverter. My question is can you mix wire guages as you go from the battery to the fuse, to the bus bar, to the breaker,

Get a quote

What gauge wire and fuse for 48v battery and 48/3000

Usually the battery bus would connect to the positive end of the distributor, with appropriate fusing/breaker/shutoff. Then on the negative back

Get a quote

Off-grid 48V system plan seeking feedback and advice on grounding

The generator I am using is portable so I will need to connect it to an earth rod when using it to run the inverter/charger. Can I use the common earth rod the battery negative,

Get a quote

What gauge wire and fuse for 48v battery and 48/3000

Then on the negative back to battery the shunt would be placed in between to track your battery state of charge. Then inverter would get

Get a quote

3. Installation and wiring examples

Use the supplied 1,5mm2 wire for the GND connection, which should be connected directly to the battery negative terminal (or the chassis of a vehicle). No other equipment should be

Get a quote

Understanding the Basics of Connecting Lithium Batteries to Inverters

Thick, high-gauge wires are needed to handle high currents safely. Connect the positive terminal of the battery to the positive input terminal of the inverter, and the negative

Get a quote

Battery connection for inverter

Connect the negative terminal of the battery to the inverter. Secondly, connect the negative black colored terminal of the battery to the inverter and fasten the negative

Get a quote

How to pre-charge an inverter easily

12V system = 7Ω resistor (50W) 24V system = 15Ω resistor (100W) 48V system = 30Ω resistor (200W) Connect the inverter to your negative and positive

Get a quote

How to Safely Connect a Battery to an Inverter: A

Learn how to safely connect your batteries to your inverter with our guide. Avoid common wiring mistakes to optimize performance and extend

Get a quote

Wiring diagram for a 48v battery bank

A 48v battery bank consists of multiple batteries connected in series or parallel to achieve the desired voltage and capacity. The wiring diagram for such a

Get a quote

HOW TO – SERIES WIRING FOR 24V/48V UPS AND INVERTERS

The positive terminal of one battery is connected to the negative terminal of the other battery, and the remaining positive and negative terminals are connected to the load or

Get a quote

Does an Inverter Need a Negative Cable Connected to the

The positive cable connects to the battery''s positive terminal, while the negative cable connects to the negative terminal. This setup ensures that the inverter can draw power

Get a quote

"Negative" 48 Volt Power: What, Why and How

Newmar provides power systems that accommodate positive and negative ground configurations. Our technical staff is well versed in these applications and can provide guidance in configuring

Get a quote

Inverter Battery Connection: Essential Tips For Safe And Efficient

Learn essential tips for safe and efficient inverter battery connection. Discover step-by-step guides, wiring techniques, and troubleshooting tips to optimize your power backup system''s

Get a quote

News

Wiring the Battery: Connect the positive terminal of the battery to the positive terminal on the inverter, and similarly, connect the negative terminals. Ensure the battery is correctly

Get a quote

Does an Inverter Need a Negative Cable Connected to the Battery

The positive cable connects to the battery''s positive terminal, while the negative cable connects to the negative terminal. This setup ensures that the inverter can draw power

Get a quote

Calculate Battery Size For Any Size Inverter (Using

Instructions! Inverter runtime: is the total number of hours you would need to run your load on an inverter Inverter input Volts (V): Are you

Get a quote

"Negative" 48 Volt Power: What, Why and How

Newmar provides power systems that accommodate positive and negative ground configurations. Our technical staff is well versed in these applications

Get a quote

Understanding the Basics of Connecting Lithium

Thick, high-gauge wires are needed to handle high currents safely. Connect the positive terminal of the battery to the positive input terminal of the

Get a quote

Inverter has a Spark with Battery Connection

When you connect an inverter to a battery the capacitors inside the inverter charge very quickly and this causes a spark at the battery terminal. To prevent this spark from connecting batteries to

Get a quote

How to Wire Inverter to Battery – No Sparks, Just Power

Wiring an inverter to a battery isn''t rocket science—but get it wrong, and you could fry your gear or drain your power fast. This quick guide shows you how to do it safely and

Get a quote

Groundin Battery Minus?

Hi there I have built a 48v system with a Quattro installed the battery minus should always go to earth terminal also, I would imagine the easy solar has a grounding point with a

Get a quote

Can I Attach My Small Inverter Directly to the Battery?

Conversely, a 24V inverter connected to a 12V battery will underperform or fail to start. Always check the inverter''s specifications label for its voltage range.

Get a quote

What gauge wire and fuse for 48v battery and 48/3000 inverter

Then on the negative back to battery the shunt would be placed in between to track your battery state of charge. Then inverter would get something like a 70V 125A mega

Get a quote

48v Battery hook up

I now have purchased a further 100ah 48v powerwall type battery again with internal bms, so want to integrate that into the system using supplied 25mm cables. Now i

Get a quote

How to connect 4 12v batteries to make 48v?

To create a 48V power system with four 12V batteries, connect them in series. Start by linking the positive terminal of the first battery to the

Get a quote

How to Wire Inverter to Battery – No Sparks, Just Power

Wiring an inverter to a battery isn''t rocket science—but get it wrong, and you could fry your gear or drain your power fast. This quick guide shows

Get a quote

How to Safely Connect a Battery to an Inverter: A Step-by-Step

Learn how to safely connect your batteries to your inverter with our guide. Avoid common wiring mistakes to optimize performance and extend system life.

Get a quote

System Installation Guide: Electrical Connection

Step 4: The input port of the inverter is connected to the battery. Note that the positive pole is connected to the positive pole and the negative pole is connected to the negative pole. The

Get a quote

6 FAQs about [Negative 48v battery connected to inverter]

Can you wire an inverter to a battery?

Wiring an inverter to a battery isn’t rocket science—but get it wrong, and you could fry your gear or drain your power fast. This quick guide shows you how to do it safely and efficiently. Whether you're setting up for backup power or going off-grid, here’s how to get it right. How to wire an inverter to a battery?

How do you connect an inverter to a battery without sparking?

To connect battery terminal wires without sparking, the positive wire is connected to its terminal first and negative wire in the last. Double check all connections then turn the inverter on. 3. Which wire is used to connect an inverter and a battery?

How to install a battery inverter?

1. Wrenches or pliers for tightening connections 2. Cable cutters and strippers to prepare the wires 3. A multimeter to check the voltage 4. Appropriate battery cables of correct sizes typically red for positive and black for negative terminal iii. Connect the positive terminal of the battery to the inverter

What happens if a battery is not connected to the inverter?

A proper connection between the battery and the inverter helps prevent overcharging and overdischarging. Improper connection between the inverter and the battery may result in the inverter failing to accurately read the battery's voltage information, which may cause the battery to be overcharged or over-discharged.

Do inverters and batteries need to match?

The inverter and batteries must match in terms of voltage, capacity, and power output. If you are using a 12V battery, then the input voltage of the inverter must match the battery voltage. If the specifications of the battery and the inverter do not match, the system will not operate stably and may even damage the equipment.

What is battery connection for inverter?

An battery connection for inverter is made in a diligent way to achieve proper operation, life span and safety constraint. This article enlightens the features, risks and battery connection for inverter along with specific safety measures, its hazards and troubleshooting strategies.

Guess what you want to know

-

Can the inverter be connected to a 48V lithium battery

Can the inverter be connected to a 48V lithium battery

-

Can a 12 volt inverter be connected to a 48v battery

Can a 12 volt inverter be connected to a 48v battery

-

Should the battery be connected to the inverter in parallel or in series

Should the battery be connected to the inverter in parallel or in series

-

Solar panel battery connected to inverter

Solar panel battery connected to inverter

-

Does the inverter for the Philippine communication base station have a battery when connected to the grid

Does the inverter for the Philippine communication base station have a battery when connected to the grid

-

Battery cabinet positive and negative poles connected incorrectly

Battery cabinet positive and negative poles connected incorrectly

-

Battery inverter 48V 60V universal

Battery inverter 48V 60V universal

-

Can a home battery be connected to an inverter

Can a home battery be connected to an inverter

-

High voltage battery connected to inverter

High voltage battery connected to inverter

-

Can a 38v lithium battery be used with a 48v inverter

Can a 38v lithium battery be used with a 48v inverter

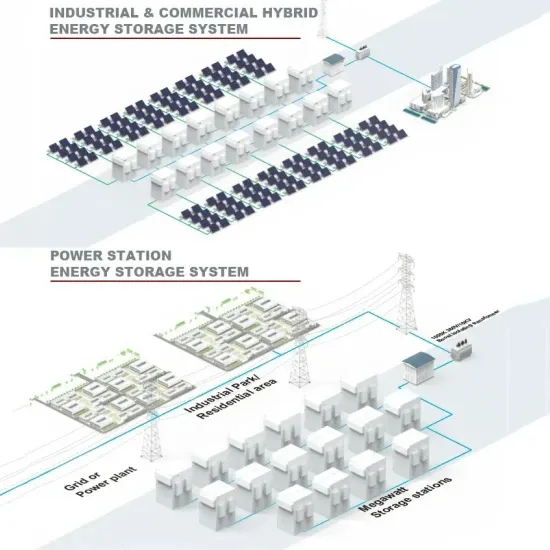

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.