Can all inverters use lithium batteries?

Not all inverters are designed to work with lithium batteries, so it''s essential to ensure that your chosen inverter can support this type of battery. The first thing you need to

Get a quote

How to Safely Connect a Battery to an Inverter: A Step-by-Step

Learn how to safely connect your batteries to your inverter with our guide. Avoid common wiring mistakes to optimize performance and extend system life.

Get a quote

Frequently Asked Questions About Power Inverters | DonRowe

In these cases, it''s a good idea to have an extra deep cycle battery for the inverter (installed close to the inverter), cabled to the starting battery. It is recommended to install a battery isolator

Get a quote

What Size Inverter To Charge E-Bike Battery? [With

But if you choose a smaller inverter than required then it won''t charge your battery. Ebike Inverter Size Chart You will have to pick an inverter size

Get a quote

Can A 12 Volt Inverter Use A 9 Volt Battery? Power Compatibility

No, a 9 Volt battery cannot effectively power a 12 Volt inverter. The primary reason is that most inverters require a voltage that matches their specifications to function properly.

Get a quote

Are Power Inverters Bad For Your Car? Here''s What You Need

Power inverters are devices that convert DC (direct current) power from a car battery into AC (alternating current) power that can be used to run various electronic devices.

Get a quote

Compatibility of Lithium-Ion Batteries with Existing Inverters

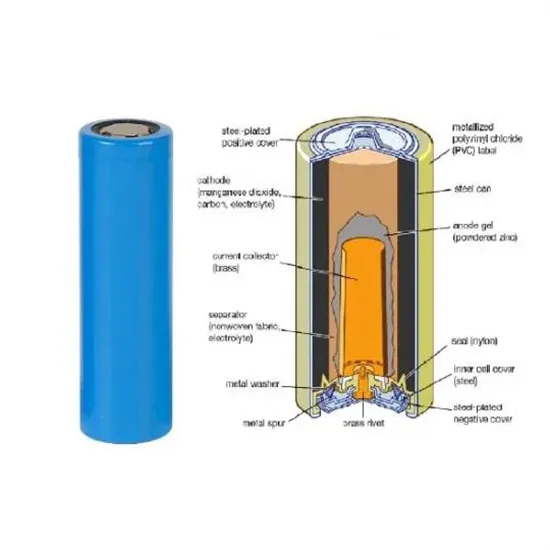

Lithium-ion batteries are a type of rechargeable battery that has gained widespread use because their high energy density and efficiency. Unlike traditional lead-acid batteries, they offer a

Get a quote

What Uses a 9V Battery? (Devices List & Why)

The lifespan of a 9V battery can vary quite a bit, depending on factors like usage and the type of the battery itself (alkaline, lithium, etc.). An

Get a quote

Can a 12V Inverter Use a 9V Battery?

No, a 12V inverter cannot efficiently run on a 9V battery. Inverters are designed to convert DC (direct current) to AC (alternating current) at a specific voltage, and a 12V inverter

Get a quote

Why can''t I power everything with a 9 V DC battery?

My question is fairly simple: Why can''t we use 9 V DC batteries to run everything in the world? Because it''s DC, and we need AC to run appliances. Answer: Use an inverter to

Get a quote

How Long Will A 12V Battery Last With an Inverter

This is where the magic of a 12v battery and inverter come in. They can transform your 12v battery, typically found in cars, into a portable power

Get a quote

How long will a 12v battery last with inverter

How long will a 12v battery last with an inverter? Here is a completed explication on the factors that affect the run time of 12v battery and

Get a quote

12 Volt Battery Inverter: How Long it will Last

However, you can determine how long will a 12 volt battery run an inverter depending on how many watts load and amp-hour the battery has. In

Get a quote

Can I Use a 12V Plug on a 9V Device? Exploring Voltage

In this article, we will delve into the question of whether it is possible to use a 12V plug on a 9V device. By understanding the relationship between voltage and electrical devices,

Get a quote

Do LiFeP04 batteries need a specific kind of inverter?

I found a 1000W pure sine wave inverter that has good reviews and looks awesome, but the manufacturer said "this device would not work with Lithium Iron Phosphate batteries

Get a quote

What Inverter Size Do You Need to Run a Freezer?

But we can make some general assumptions. The calculation is: get the maximum wattage used by the freezer and add 25% to it. The result is the ideal inverter size. You can get a larger

Get a quote

What Will An Inverter Run & For How Long? (With Calculator)

So I''m gonna explain to you guys in simple words about what you can run on your any size inverter and what are the key point to keep in mind. And also how long your inverter

Get a quote

Can a 9 Volt Battery Be Used with Duralast Power Inverter

Using a 9-volt battery can lead to inadequate power supply, preventing the inverter from functioning correctly. According to the manufacturer''s specifications, using a voltage

Get a quote

Can grid-tie solar inverters run on batteries instead of photovoltaic

You can however, have the battery inputs correctly connected to the inverter, an AC grid or generator connection and NO PV, then just charge your batteries through the build in

Get a quote

Can a 9 Volt Battery Be Used With a Duralast Power Inverter?

A 9V battery has a low capacity (around 500–600 mAh), meaning it can''t supply the continuous power needed by an inverter. Inverters demand a stable current over time, which a

Get a quote

Charging Battery While Connected To Inverter: The

Power source options How to connect the charging system Following the outlined method below, you can ensure uninterrupted power by charging your battery

Get a quote

What Will An Inverter Run & For How Long? (With Calculator)

Learn how to safely connect your batteries to your inverter with our guide. Avoid common wiring mistakes to optimize performance and extend

Get a quote

Can One 12 Volt Battery Run a 1000 Watt Inverter?

Yes, a single 12-volt battery can run a 1000-watt inverter, but the runtime depends on several factors such as the battery''s capacity, the inverter''s efficiency, and the load

Get a quote

10 Tips for Using a Power Inverter Correctly

Power inverter that converts DC power to AC power provides a great convenience people''s lives, especially in home appliances, such as air conditioner, refrigerator, TV, VCR,

Get a quote

6 FAQs about [Can the inverter be used with a nine-volt battery ]

Can a 12V battery be used as an inverter?

If you are using a 12V battery, then the input voltage of the inverter must match the battery voltage. If the specifications of the battery and the inverter do not match, the system will not operate stably and may even damage the equipment. In addition, choose the right inverter power and battery capacity for your home or commercial needs.

Do inverters and batteries need to match?

The inverter and batteries must match in terms of voltage, capacity, and power output. If you are using a 12V battery, then the input voltage of the inverter must match the battery voltage. If the specifications of the battery and the inverter do not match, the system will not operate stably and may even damage the equipment.

Does an inverter convert a battery into a 120 volt battery?

Our batteries come in different voltages (12,24, & 48v) But AC appliances required 120 volts (because our grid power comes in 120 volts). So an inverter will convert the lower voltage of the battery into 120 volts in order to run AC appliances If playback doesn't begin shortly, try restarting your device.

Do inverters need to be connected to batteries?

Connecting inverters to batteries is an important part of an off-grid power solution or backup power system, and the right connections ensure that the system runs efficiently.

How many volts can a 9v battery supply?

You can step it up to 120 V, but it will deliver microamps. 9V batteries have a high internal resistance so they can't supply much current. You would also need a really large step-up transformer and an inverter as you can't power a transformer with just DC.

How much power does a 12V inverter use?

For example: If you're running a 1500W inverter on your 12v battery with 1000 watts of total AC load. So your inverter will be consuming 83 amps (amps = watts/battery volts) from the battery for which you'll need a very thick cable. using a thin cable in this scenario can damage the inverter or you'll not be able to run your load.

Guess what you want to know

-

Can a 38v lithium battery be used with a 48v inverter

Can a 38v lithium battery be used with a 48v inverter

-

Can the 14 8V battery be used with the inverter

Can the 14 8V battery be used with the inverter

-

48v battery with inverter can be used for several hours

48v battery with inverter can be used for several hours

-

Can a lead-acid battery be used with an inverter

Can a lead-acid battery be used with an inverter

-

Base station lithium battery energy storage 30kw inverter company

Base station lithium battery energy storage 30kw inverter company

-

Large single lithium battery plus inverter

Large single lithium battery plus inverter

-

48-72v lead-acid lithium battery universal inverter

48-72v lead-acid lithium battery universal inverter

-

High voltage battery connected to inverter

High voltage battery connected to inverter

-

How to eliminate the problem of small grid-connected battery in inverter of communication base station

How to eliminate the problem of small grid-connected battery in inverter of communication base station

-

What size battery should I use with an 8600w inverter

What size battery should I use with an 8600w inverter

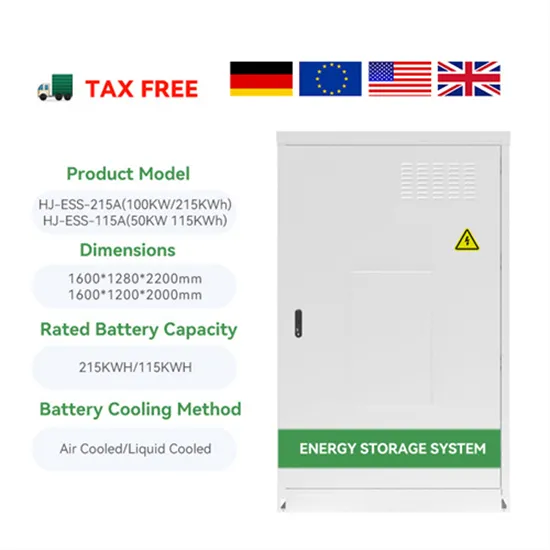

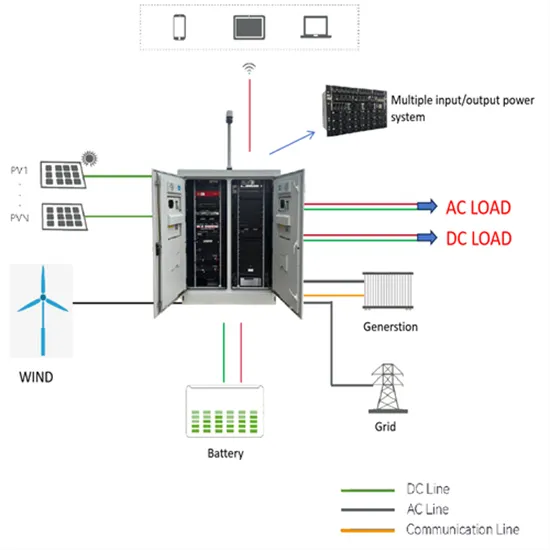

Industrial & Commercial Energy Storage Market Growth

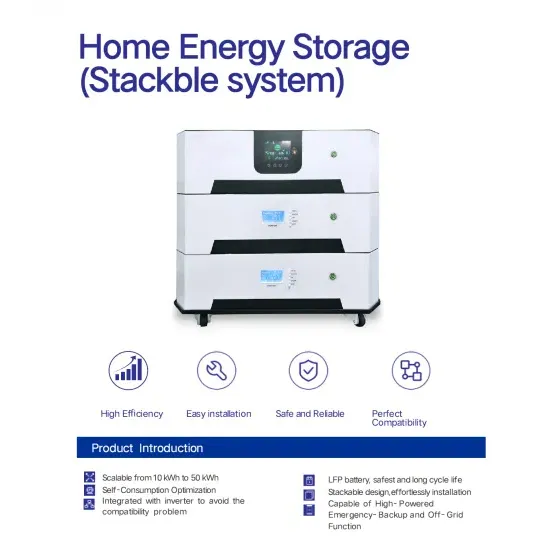

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.