White Paper Ensuring the Safety of Energy Storage Systems

The potential safety issues associated with ESS and lithium-ion bateries may be best understood by examining a case involving a major explosion and fire at an energy storage facility in

Get a quote

5.01MWh User Manual for liquid-cooled ESS

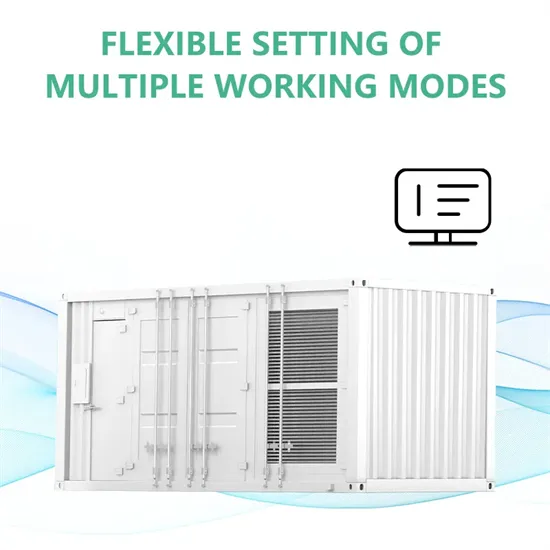

The energy storage system of this product adopts integrated design, which integrates the energy storage battery cluster and battery management system into a 20-foot container, which

Get a quote

Microsoft Word

An automatic smoke detection system or radiant-energy detection system shall be installed in rooms, walk-in units and areas containing energy storage systems as required in

Get a quote

Battery Energy Storage Systems: Main Considerations for Safe

This webpage includes information from first responder and industry guidance as well as background information on battery energy storage systems (challenges & fires), BESS

Get a quote

Fire Inspection Requirements for Battery Energy

NFPA 855: Standard for the Installation of Stationary Energy Storage Systems: This standard provides requirements for the installation and maintenance of

Get a quote

New York Battery Energy Storage System Guidebook for

The Battery Energy Storage System Guidebook (Guidebook) helps local government officials, and Authorities Having Jurisdiction (AHJs), understand and develop a battery energy storage

Get a quote

(2023) Energy Storage Field Inspection Checklist Template

Providing an online list of inspection requirements will reduce informational barriers between inspectors and installers, helping to ensure that all items in the inspection

Get a quote

Fire Inspection Requirements for Battery Energy Storage Systems

NFPA 855: Standard for the Installation of Stationary Energy Storage Systems: This standard provides requirements for the installation and maintenance of stationary energy storage

Get a quote

Comprehensive Guide to Inspecting Fully Integrated

To ensure the reliability, efficiency, and safety of these systems, regular inspections are essential. This article will guide you through the key

Get a quote

ENERGY STORAGE SYSTEMS SAFETY FACT SHEET

An energy storage system, often abbreviated as ESS, is a device or group of devices assembled together, capable of storing energy in order to supply electrical energy at a later time. Battery

Get a quote

SPCC Guidance for Regional Inspectors

Various provisions of the SPCC rule relate to the inspection, evaluation, and testing of containers, associated piping, and other oil-containing equipment. Different requirements

Get a quote

Process Safety Management for Storage Facilities

Nevertheless, facilities must collect information on equipment that is part of the PSM‐covered process. Typical equipment may include: storage tanks, piping, pumps, containers, pressure

Get a quote

Hydrogen Vehicle and Infrastructure Codes and Standards

General Safety Requirements International Fire Code (International Code Council, 2009) 2209.5 Safety Precautions 2211.7 Repair Garages for Vehicles Fueled by Lighter-than-Air Fuels

Get a quote

Energy Storage Solutions Inspection Checklist and

Check the product''s storage capacity or battery life to ensure it meets the specified requirements. Inspect the product''s cooling system or ventilation to

Get a quote

DoE Fuel Storage Tanks Regulations

3.9.5 Ten (10) year inspections - In addition to the requirements of Clause 3.9.3, all Licence Holders must perform a detailed inspection of fuel storage tanks.

Get a quote

Comprehensive Guide to CSC Certification for BESS Containers

Battery Energy Storage Systems (BESS) containers, when used for transportation or shipping, generally need to comply with certain regulations and standards to ensure safety

Get a quote

Microsoft Word

Guidance for documenting or verifying compliance with current CSR is also provided to facilitate the review and approval of ESS installations. Appendices are provided that augment the core

Get a quote

Codes and Standards for Energy Storage System

At the workshop, an overarching driving force was identified that impacts all aspects of documenting and validating safety in energy storage; deployment of energy storage systems is

Get a quote

What tests should be done on energy storage containers?

What tests should be done on energy storage containers? To ensure the safety, efficiency, and longevity of energy storage containers, the following evaluations are essential:

Get a quote

Comprehensive Guide to Inspecting Fully Integrated BESS

To ensure the reliability, efficiency, and safety of these systems, regular inspections are essential. This article will guide you through the key aspects of inspecting a

Get a quote

WHAT IS CSC CERTIFICATE AND CSC PLATE FOR CONTAINERS?

The goal of CSC is to formalize international safety requirements for structural design and consistent inspection and maintenance of cargo containers. Overall, CSC ensures

Get a quote

RCRA Training Module: Introduction to Containers (40 CFR

This module reviews two sets of regulatory requirements for containers: requirements that pertain to the management of hazardous waste containers and regulations governing residues of

Get a quote

Energy Storage Solutions Inspection Checklist and Template

Check the product''s storage capacity or battery life to ensure it meets the specified requirements. Inspect the product''s cooling system or ventilation to ensure it is free from obstructions or

Get a quote

Quality Requirements for Battery Energy Storage Systems

The purpose of this quality requirements specification (QRS) is to specify quality management requirements and the proposed extent of purchaser intervention activities for the procurement

Get a quote

6 FAQs about [Energy storage container inspection requirements]

What inspection and testing requirements apply to bulk storage containers?

Some inspection and testing provisions apply to bulk storage containers at onshore facilities (other than production facilities). Inspection and/or testing requirements also apply to other components of a facility that might cause a discharge (such as vehicle drains, foundations, or other equipment or devices).

What if energy storage system and component standards are not identified?

Energy Storage System and Component Standards 2. If relevant testing standards are not identified, it is possible they are under development by an SDO or by a third-party testing entity that plans to use them to conduct tests until a formal standard has been developed and approved by an SDO.

What are the requirements for retest & inspection of intermediate bulk containers?

A written record of the dates and results of the tests, including the name and address of the person performing the test, is to be retained by the tank owner or authorized agent. Requirements for retest and inspection of Intermediate Bulk Containers (IBCs) are specified in 49 CFR 180.352. Requirements depend on the IBC shell material.

How do you inspect a container?

Combine visual inspection with another testing technique (such as non destructive shell testing). Following a regular schedule and whenever material repairs are made. Inspect outside of container for signs of deterioration and discharges. Frequently.

Do electric energy storage systems need to be tested?

It is recognized that electric energy storage equipment or systems can be a single device providing all required functions or an assembly of components, each having limited functions. Components having limited functions shall be tested for those functions in accordance with this standard.

Do energy storage systems need a CSR?

Until existing model codes and standards are updated or new ones developed and then adopted, one seeking to deploy energy storage technologies or needing to verify an installation’s safety may be challenged in applying current CSRs to an energy storage system (ESS).

Guess what you want to know

-

Requirements and standards for energy storage container installation

Requirements and standards for energy storage container installation

-

Congo Kinshasa container energy storage project requirements

Congo Kinshasa container energy storage project requirements

-

Energy storage container system installation requirements

Energy storage container system installation requirements

-

Belgian energy storage station container manufacturer

Belgian energy storage station container manufacturer

-

Energy Storage Container Organizational Structure

Energy Storage Container Organizational Structure

-

Togolese energy storage container brand

Togolese energy storage container brand

-

Container Energy Storage Specifications

Container Energy Storage Specifications

-

Colombian energy storage container manufacturer

Colombian energy storage container manufacturer

-

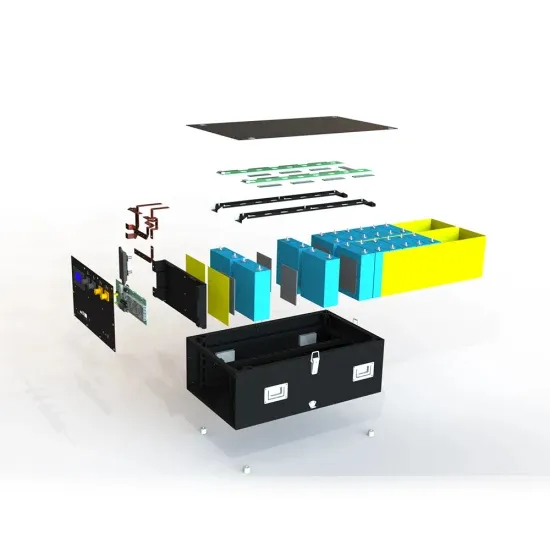

What are the components of the energy storage battery container

What are the components of the energy storage battery container

-

Huijue Electric Energy Storage Container

Huijue Electric Energy Storage Container

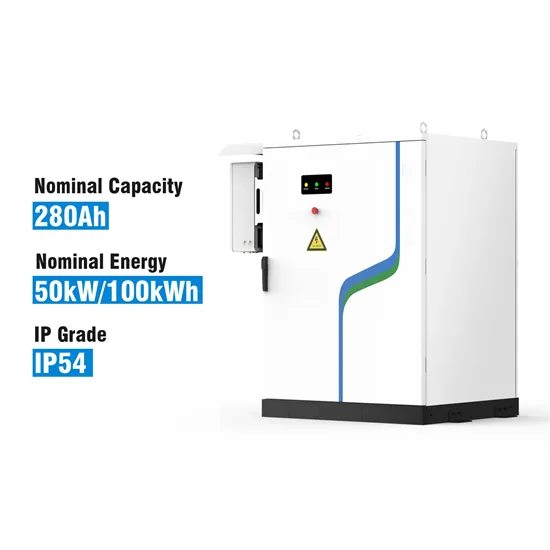

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.