Summary of stability analysis and collaborative control technology

Abstract To sort out the stability analysis and collaborative control technology of multi PCS parallel connection in grid type energy storage power stations, and further explore

Get a quote

2021 The 2nd International Conference on Power

With the continuous improvement of the fine management requirements of large-scale clustered energy storage power stations, the existing problems of the informationized

Get a quote

Quality assurance methods for energy storage systems

However, proving that an ESS is fit for purpose while complying with all relevant legislation is not a straightforward task. This article looks at the issues involved, and possible

Get a quote

Energy Storage Quality Assurance: How to Prevent Costly

Learn how to prevent costly energy storage defects with effective QA, supplier vetting, and factory testing for reliable long-term performance.

Get a quote

Energy Storage Quality Control | Applus+ USA

They ensure reliable BESS solutions that meet industry standards and quality requirements and improve BESS performance, which is measured through key indicators such as capacity,

Get a quote

Energy Storage Quality Supervision: Why It Matters Now More

Quality supervision in energy storage isn''t just about ticking boxes – it''s the guardian angel of battery farms and grid-scale projects. Think of it as a cross between a

Get a quote

Industrial and commercial energy storage vs energy

The article first introduces the concept of industrial and commercial energy storage and energy storage power stations, outlining their respective roles in

Get a quote

Coordinating regulation reliability and quality of pumped storage

Abstract As the largest electricity storage facility, pumped storage is crucial for power systems but faces significant trade-offs between regulation quality for variable

Get a quote

Design of Remote Fire Monitoring System for Unattended

At the same time, combined with the pilot construction expe-rience of unattended substation fire remote monitoring system project of State Grid Shenyang Electric Power Co., Ltd, a design

Get a quote

Analysis of equipment quality problem and control strategies for

The new energy storage system of high - voltage transformerless battery energy storage power station came into being. The system can meet the construction requirements of

Get a quote

Key Regulations for Quality Control in Independent Energy Storage Power

As renewable energy adoption accelerates, independent energy storage systems have become critical for grid stability. This article explores the latest quality supervision regulations shaping

Get a quote

What are the control strategies for energy storage power stations

The control strategies for energy storage power stations encompass various techniques aimed at optimizing performance and reliability, including: 1) Real-time monitoring

Get a quote

Capacity optimization strategy for gravity energy

The integration of renewable energy sources, such as wind and solar power, into the grid is essential for achieving carbon peaking and

Get a quote

Battery storage power station – a comprehensive guide

The guide covers the construction, operation, management, and functionalities of these power stations, including their contribution to grid stability, peak shaving, load shifting, and backup

Get a quote

Battery technologies for grid-scale energy storage

Energy-storage technologies are needed to support electrical grids as the penetration of renewables increases. This Review discusses the application and development

Get a quote

Key Regulations for Quality Control in Independent Energy

As renewable energy adoption accelerates, independent energy storage systems have become critical for grid stability. This article explores the latest quality supervision regulations shaping

Get a quote

ETAP-based Power Quality Assessment of Energy Storage Stations

A case study is conducted using ETAP to evaluate the power quality of a specific energy storage station. The assessment includes voltage deviations, voltage fluctuations, flicker, and

Get a quote

How is the quality of energy storage power station? | NenPower

In summary, the quality of an energy storage power station is fundamentally shaped by numerous interrelated elements, including technological advancements, operational

Get a quote

Energy Storage Quality Control

THE Applus+ SOLUTION Enertis Applus+''s highly specialized BESS quality control and quality assurance services cover the planning and manufacturing phases of battery energy storage

Get a quote

New energy storage design

In the field of energy storage, energy storage power stations play an important role. The application of energy storage power station technology runs through all aspects of power

Get a quote

Quality assurance methods for energy storage systems

Quality supervision in energy storage isn''t just about ticking boxes – it''s the guardian angel of battery farms and grid-scale projects. Think of it as a cross between a

Get a quote

Advancements in large‐scale energy storage

This special issue encompasses a collection of eight scholarly articles that address various aspects of large-scale energy storage. The

Get a quote

Ensuring Power Stability and Efficiency with Battery

As solar and wind power generation capacity expands across the United States, the demand for BESS continues to grow at an unprecedented

Get a quote

Lithium-ion energy storage power station design

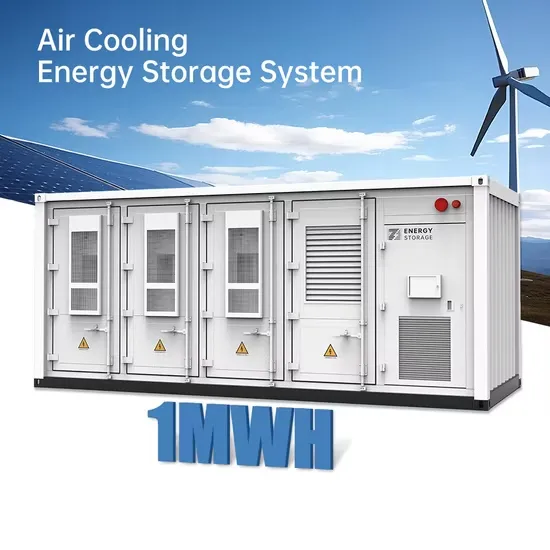

SCU provides 500kwh to 2mwh energy storage container solutions. Power up your business with reliable energy solutions. Say goodbye to high energy costs and hello to smarter solutions with

Get a quote

ETAP-based Power Quality Assessment of Energy Storage

A case study is conducted using ETAP to evaluate the power quality of a specific energy storage station. The assessment includes voltage deviations, voltage fluctuations, flicker, and

Get a quote

Technologies for Energy Storage Power Stations Safety

As large-scale lithium-ion battery energy storage power facilities are built, the issues of safety operations become more complex. The existing difficulties revolve around effective battery

Get a quote

Battery storage power station – a comprehensive guide

The guide covers the construction, operation, management, and functionalities of these power stations, including their contribution to grid stability, peak

Get a quote

Research on Key Technologies and Typical Applications of

With the advancement of energy transition, large-scale energy storage stations have become crucial support for power systems, but their safety issues have become

Get a quote

6 FAQs about [Key points for quality control of energy storage power stations]

Why is system control important for battery storage power stations?

Secondly, effective system control is crucial for battery storage power stations. This involves receiving and executing instructions to start/stop operations and power delivery. A clear communication protocol is crucial to prevent misoperation and for the system to accurately understand and execute commands.

What are battery storage power stations?

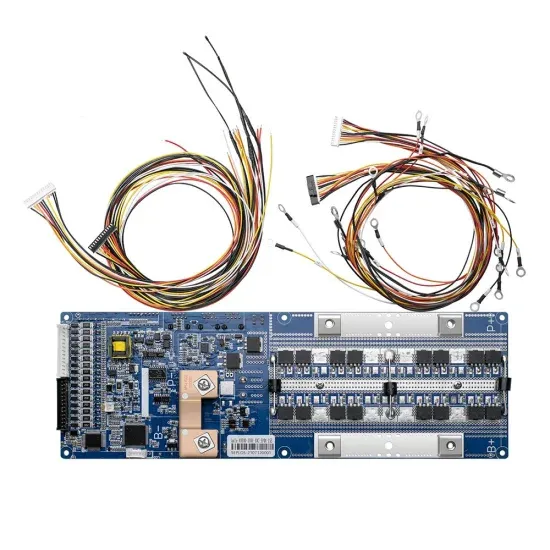

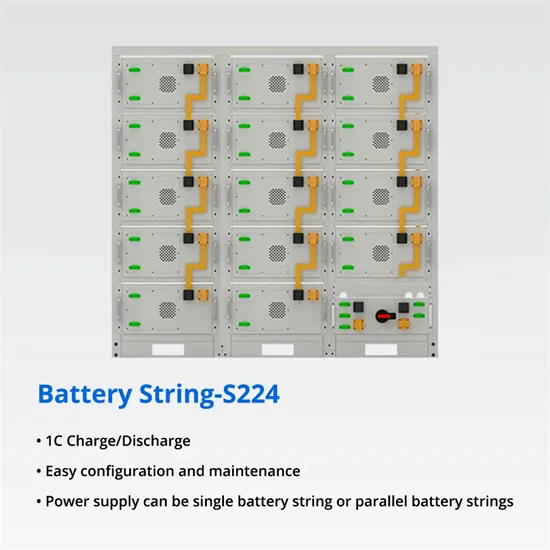

Battery storage power stations are usually composed of batteries, power conversion systems (inverters), control systems and monitoring equipment. There are a variety of battery types used, including lithium-ion, lead-acid, flow cell batteries, and others, depending on factors such as energy density, cycle life, and cost.

Why do battery storage power stations need a data collection system?

Battery storage power stations require complete functions to ensure efficient operation and management. First, they need strong data collection capabilities to collect important information such as voltage, current, temperature, SOC, etc.

What is the construction process of energy storage power stations?

The construction process of energy storage power stations involves multiple key stages, each of which requires careful planning and execution to ensure smooth implementation.

What is a battery energy storage system design plan?

Detailed battery energy storage system design plans were developed based on site surveys, geological assessments and technical specifications. This includes producing construction blueprints, drafting drawings from various disciplines (structural, civil engineering, electrical, etc.), and signing technical agreements with equipment manufacturers.

Do energy storage power plants need a maintenance plan?

At every stage, compliance with regulatory requirements, safety standards and technical specifications is critical to ensuring the successful and efficient operation of an energy storage plant. Operation and maintenance plans for energy storage power plants cover all key aspects to ensure optimal performance and reliability.

Guess what you want to know

-

Key points in energy storage product design

Key points in energy storage product design

-

Effects of large energy storage power stations

Effects of large energy storage power stations

-

What Are the Smart Energy Storage Power Stations in Kiribati

What Are the Smart Energy Storage Power Stations in Kiribati

-

What is the application market for container energy storage power stations

What is the application market for container energy storage power stations

-

Economic calculation of energy storage peak-shaving power stations

Economic calculation of energy storage peak-shaving power stations

-

Constant power supply in energy storage power stations

Constant power supply in energy storage power stations

-

Dangerous factors of energy storage batteries in power stations

Dangerous factors of energy storage batteries in power stations

-

Can energy storage power stations be placed in containers

Can energy storage power stations be placed in containers

-

BYD battery cells for energy storage power stations

BYD battery cells for energy storage power stations

-

What are India s modern energy storage power stations

What are India s modern energy storage power stations

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.