Sparton Resources Inc. VRB China Announcement

1 day ago· Sparton''s interest in the flow battery industry is a 9.975% interest in VRB Energy Inc. held through Sparton''s 90% interest in VanSpar Mining Inc.

Get a quote

Long term performance evaluation of a commercial vanadium flow battery

The system shows stable performance and very little capacity loss over the past 12 years, which proves the stability of the vanadium electrolyte and that the vanadium flow

Get a quote

Comparing the Cost of Chemistries for Flow Batteries

Researchers from MIT have demonstrated a techno-economic framework to compare the levelized cost of storage in redox flow batteries with

Get a quote

Renewable energy boosts flow battery market and

The flow battery market can be segmented based on product type, electrolyte composition, and application areas. Among product types,

Get a quote

Performance enhancement of vanadium redox flow battery with

This study investigates a novel curvature streamlined design, drawing inspiration from natural forms, aiming to enhance the performance of vanadium redox flow battery cells

Get a quote

Development status, challenges, and perspectives of key

All-vanadium redox flow batteries (VRFBs) have experienced rapid development and entered the commercialization stage in recent years due to the characteristics of

Get a quote

Long term performance evaluation of a commercial vanadium

The system shows stable performance and very little capacity loss over the past 12 years, which proves the stability of the vanadium electrolyte and that the vanadium flow

Get a quote

Vanadium Flow Batteries: Industry Growth & Potential

Thirdly, vanadium flow batteries are inherently safer compared to other battery technologies; their non-flammable, water-based vanadium electrolyte makes them less prone

Get a quote

Schmid Pekintaş targets redox flow battery cost

As the search for cost-effective longer duration energy storage technologies intensifies, a new manufacturing operation in Turkey aims to

Get a quote

The breakthrough in flow batteries: A step forward, but

Flow batteries are emerging as a transformative technology for large-scale energy storage, offering scalability and long-duration storage to

Get a quote

Vanadium Flow Battery: How It Works and Its Role in Energy

A vanadium flow battery works by circulating two liquid electrolytes, the anolyte and catholyte, containing vanadium ions. During the charging process, an ion exchange happens

Get a quote

The World''s Largest 100MW Vanadium Redox Flow

It adopts the all-vanadium liquid flow battery energy storage technology independently developed by the Dalian Institute of Chemical Physics. The

Get a quote

Are vanadium flow batteries worth the hype?

There''s a century-old technology that''s taking the grid-scale battery market by storm. Based on water, virtually fireproof, easy to recycle and cheap at scale, vanadium flow

Get a quote

Are vanadium flow batteries worth the hype?

There''s a century-old technology that''s taking the grid-scale battery market by storm. Based on water, virtually fireproof, easy to recycle

Get a quote

Vanadium Flow Battery for Home | A Complete 2024

Discover the power of the Vanadium Flow Battery for Home use! This comprehensive guide explores the technology, benefits, installation, and

Get a quote

Sichuan V-LiQuid Energy Co., Ltd.

V-Liquid is a developer and manufacturer specializing in all-vanadium flow battery technology. We focus on the research, development, production, and sales of core materials, electric stacks,

Get a quote

What Are Flow Batteries? A Beginner''s Overview

Flow batteries have a storied history that dates back to the 1970s when researchers began experimenting with liquid-based energy storage solutions. The

Get a quote

All-vanadium redox flow batteries

The most commercially developed chemistry for redox flow batteries is the all-vanadium system, which has the advantage of reduced effects of species crossover as it

Get a quote

Vanadium redox flow battery: Characteristics and

As a new type of green battery, Vanadium Redox Flow Battery (VRFB) has the advantages of flexible scale, good charge and discharge

Get a quote

China to host 1.6 GW vanadium flow battery

The all-vanadium liquid flow industrial park project is taking shape in the Baotou city in the Inner Mongolia autonomous region of China, backed

Get a quote

What is all-vanadium liquid flow battery energy storage?

The all-vanadium liquid flow battery represents a sophisticated and innovative approach to energy storage, characterized by its unique mechanism that utilizes vanadium

Get a quote

Sichuan V-LiQuid Energy Co., Ltd.

Sichuan V-LiQuid Energy Co., Ltd.V-Liquid is a developer and manufacturer specializing in all-vanadium flow battery technology. We focus on the research, development, production, and

Get a quote

Schmid Pekintaş targets redox flow battery cost reduction with new

As the search for cost-effective longer duration energy storage technologies intensifies, a new manufacturing operation in Turkey aims to bring flow battery systems into

Get a quote

The breakthrough in flow batteries: A step forward, but not a

Flow batteries are emerging as a transformative technology for large-scale energy storage, offering scalability and long-duration storage to address the intermittency of

Get a quote

Flow batteries for grid-scale energy storage

Their work focuses on the flow battery, an electrochemical cell that looks promising for the job—except for one problem: Current flow batteries rely on vanadium, an energy

Get a quote

An Open Model of All-Vanadium Redox Flow Battery Based on

Based on the component composition and working principle of the all-vanadium redox flow battery (VRB), this paper looks for the specific influence mechanism of the

Get a quote

How Vanadium Flow Batteries Work

Here''s how our vanadium flow batteries work. The fundamentals of VFB technology are not new, having been first developed in the late 1980s. In contrast to lithium-ion batteries which store

Get a quote

6 FAQs about [Turkey s new all-vanadium liquid flow battery]

Could vanadium flow batteries be the wave of the future?

There’s a century-old technology that’s taking the grid-scale battery market by storm. Based on water, virtually fireproof, easy to recycle and cheap at scale, vanadium flow batteries could be the wave of the future. Development of redox flow batteries. A historical bibliography - ScienceDirect

Are flow batteries the future of energy storage?

Flow batteries are emerging as a transformative technology for large-scale energy storage, offering scalability and long-duration storage to address the intermittency of renewable energy sources like solar and wind.

Does a 12-year-old vanadium flow battery leak?

A commercially deployed 12-year-old vanadium flow battery is evaluated. Capacity and efficiency are stable since commissioning; no leakages occur. Small capacity loss is restored by rebalancing procedure of the electrolyte. Electrochemical impedance spectroscopy is applied to investigate stack degradation.

Why do flow batteries use vanadium chemistry?

This demonstrates the advantage that the flow batteries employing vanadium chemistry have a very long cycle life. Furthermore, electrochemical impedance spectroscopy analysis was conducted on two of the battery stacks. Some degradation was observed in one of the stacks reflected by the increased charge transfer resistance.

What are vanadium redox flow batteries (VRFB)?

Amid diverse flow battery systems, vanadium redox flow batteries (VRFB) are of interest due to their desirable characteristics, such as long cycle life, roundtrip efficiency, scalability and power/energy flexibility, and high tolerance to deep discharge [, , ].

Are flow batteries better than traditional lithium-ion batteries?

Flow batteries, which store energy in liquid electrolytes housed in separate tanks, offer several advantages over traditional lithium-ion batteries.

Guess what you want to know

-

Dominica s new vanadium titanium GW-grade all-vanadium liquid flow energy storage battery

Dominica s new vanadium titanium GW-grade all-vanadium liquid flow energy storage battery

-

Indonesia s new vanadium titanium GW-grade all-vanadium liquid flow energy storage battery

Indonesia s new vanadium titanium GW-grade all-vanadium liquid flow energy storage battery

-

How much is the all-vanadium liquid flow battery

How much is the all-vanadium liquid flow battery

-

Home energy storage all-vanadium liquid flow battery

Home energy storage all-vanadium liquid flow battery

-

Honduras all-vanadium liquid flow energy storage battery

Honduras all-vanadium liquid flow energy storage battery

-

Italian all-vanadium liquid flow energy storage battery

Italian all-vanadium liquid flow energy storage battery

-

Sri Lanka s all-vanadium liquid flow energy storage battery

Sri Lanka s all-vanadium liquid flow energy storage battery

-

The best enterprise of all-vanadium liquid flow battery

The best enterprise of all-vanadium liquid flow battery

-

Yaounde s new all-vanadium redox flow battery

Yaounde s new all-vanadium redox flow battery

-

Vanadium titanium all-vanadium liquid flow energy storage battery

Vanadium titanium all-vanadium liquid flow energy storage battery

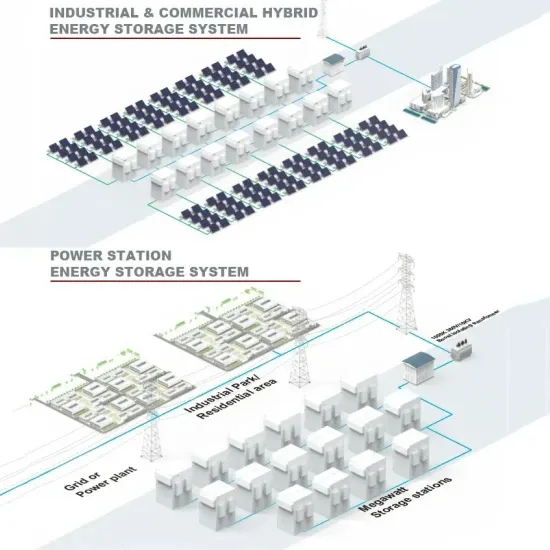

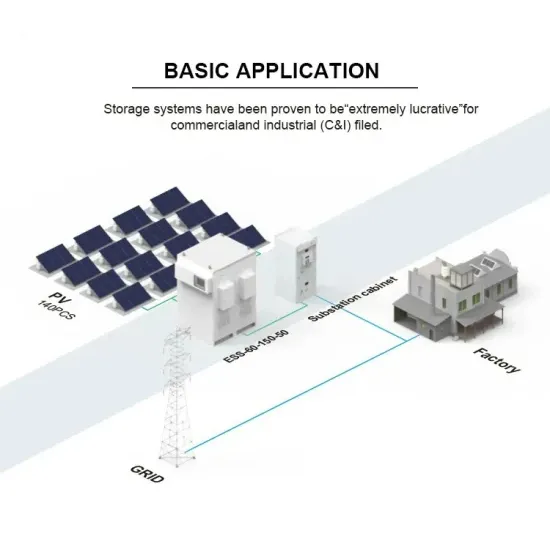

Industrial & Commercial Energy Storage Market Growth

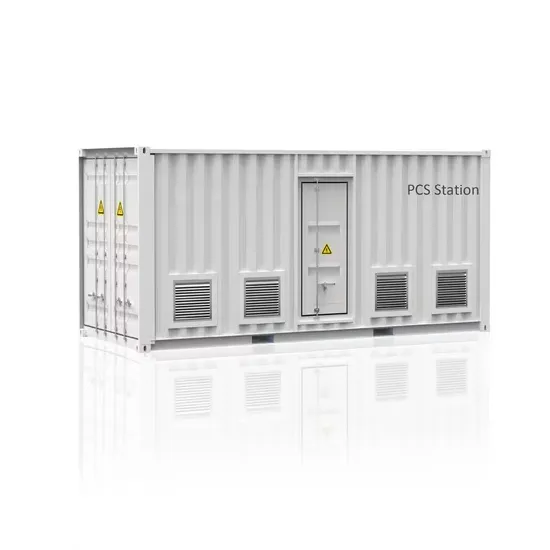

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

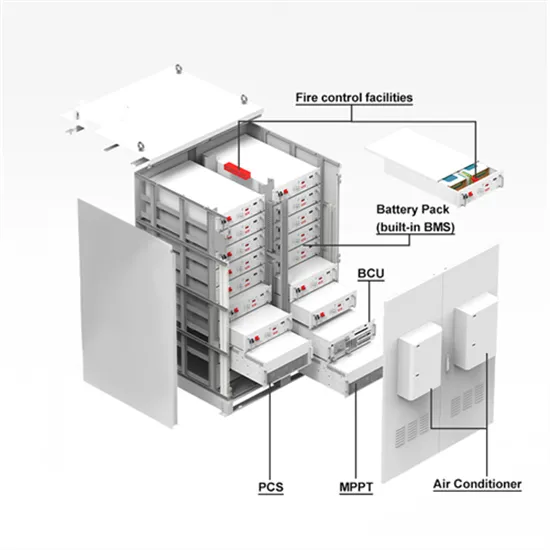

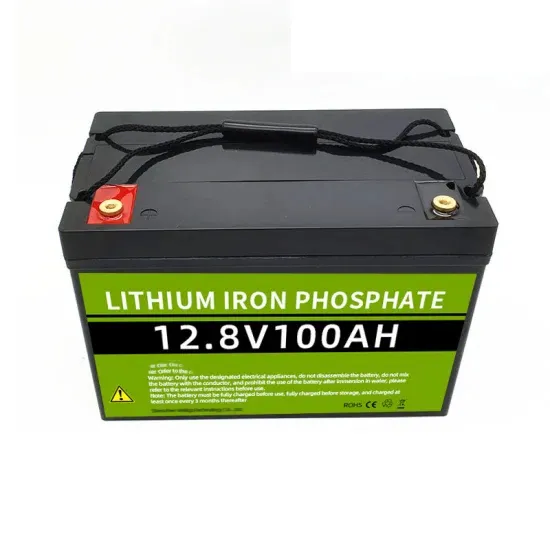

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.