Battery To Inverter Wire Size Calculator: What Size

The battery to inverter wire size calculator below will provide the size of the Copper wire that you need in AWG (American Wire Gauge) and

Get a quote

14.8v car battery to 12.6 3s Li-ion charger

I heard that some 12v inverters wont work on more than 15v. I suggested 3s originally because i i read 3.6v-4.2v is ideal for long battery life of 18650 li-ion cells.

Get a quote

Can I run a 2000 watt inverter on a 12V battery?

When camping in the wild, experiencing power outages at home, RV travel, or sailing on a ship, a 2000W inverter can convert the DC power of the battery into AC power to

Get a quote

Looking for 12V@10A dc-dc converter from 14.8V @10A battery

To achieve the low dropout operation from 12.8V to 12V, choose a controller with low minimum off-time spec, for example the LM25145 has a toff-min spec of 140ns and provides high max

Get a quote

Circuit to convert 14.8v battery with max 4a discharge current into

The best option I have found is using 3 step down buck converter modules. But is there a way to combine 3 separate buck converters to reduce the size of the PCB to as small

Get a quote

14.8 volts for 12 volt wii? : r/ECE

14.8 V sounds like 4x 3.7V cells in series. That makes your voltage range 16.8V to 12.8V depending on charge level and temperature. You need some sort of regulator. A linear

Get a quote

Is 13.4 volts too high for devices requiring 12 V?

Most mounts and other astro equipment that are built to use nominal 12V lead acid batteries as power supplies will work fine with the 13.8V regulated power supplies. The no load

Get a quote

What Size Inverter Can I Run Off a 100Ah Battery? A

This capacity influences how long an inverter can run appliances before needing a recharge. However, battery capacity alone doesn''t dictate inverter size. The inverter converts

Get a quote

Radio requires 13.8 volts, I only have a 12 volt battery system

Could I have that much loss with the 100 foot run of 10 gauge? How can I utilize my battery bank to operate my radio at the full 100 watts during emergencys? Can i somehow

Get a quote

Frequently Asked Questions About Power Inverters | DonRowe

Power Inverter FAQ Frequently Asked Questions about Power Inverters What does a power inverter do, and what can I use one for? Using an inverter for basic emergency home backup

Get a quote

Running a 12V Solenoid using a 14.8 Volt Battery

You can have either the 14.8v or 11.1V battery with a 12v buck or boost converter for powering the solenoid and keep things in the target voltage. Then based on your battery life

Get a quote

14.8 volts for 12 volt wii? : r/ECE

14.8 V sounds like 4x 3.7V cells in series. That makes your voltage range 16.8V to 12.8V depending on charge level and temperature. You need some sort of regulator. A linear would

Get a quote

Do LiFeP04 batteries need a specific kind of inverter?

LiFeP04, tho, are almost perfect. a 4S pack has a fully charged voltage of 14.4-14.6, and a fully discharged voltage of 10 or so. That''s perfect for most any 12V inverter out there.

Get a quote

How to ''convert'' 12 volt pump to 110?

Found a 12 volt pump to use for our camp shower but it is 12 volt,how would I go about converting it to 110? Would a battery charger work?? This is the...

Get a quote

how to use 12V inverter on 24 volt (2 battery) system

Option 1: keep the 24v, sell the inverter and buy a 24v one. Option 2: make the entire system 12V. If you don''t have more parts connected, it''s as simple as connect the battery in parallel and

Get a quote

How to convert 14.8V @ 10A Lipo battery output to 12V@10A

Since the cutoff voltage for 14.8V battery is 12.8V, the dc-dc converter is expected to regulate 12V even when the input voltage is 12.8V.But, I am not getting any dc-dc converter

Get a quote

11.1v to 12v vs 14.8v to 12v

I need to get either a 11.1v battery to 12v or 14.8v battery to 12v for a camera. The current draw will be less than 250mah. I was wondering what the cheapest and easiest way to

Get a quote

Calculate Battery Size For Any Size Inverter (Using Our Calculator)

So I have made it easy for you, use the calculator below to calculate the battery size for 200 watt, 300 watt, 500 watt, 1000 watt, 2000 watt, 3000 watt, 5000-watt inverter

Get a quote

What Appliances can run on a Power inverter?

A power inverter is a device that takes in direct current (DC) and converts this into alternating current (AC) so it can power AC appliances. Firstly there are two

Get a quote

Can I Run a 12V Inverter on a 24V Battery?

To summarize, it is not feasible to run a 12V inverter directly on a 24V battery, which can lead to inverter damage and safety hazards. However, this problem can be

Get a quote

Can a 12V 7Ah UPS Inverter ( 220v ) run with a 14.8V 150Ah Battery

In this video I will do a test to find out if a 600va computer UPS inverter can handle 14.8 v 150Ah truck battery because it is designed to operate with a...

Get a quote

Calculate Battery Size For Any Size Inverter (Using

So I have made it easy for you, use the calculator below to calculate the battery size for 200 watt, 300 watt, 500 watt, 1000 watt, 2000

Get a quote

Looking for 12V@10A dc-dc converter from 14.8V @10A battery

At 14.8 volts your linear regulator will be 81% efficient, at 12.8 volts it will be 93%. That''s going to be as good or better than most switching converters. You could use 5 of these

Get a quote

Reducing 14.8Vdc to 12Vdc | Electronics Forums

However, my educated guess (based on long experience with alarm panel power supplies) is that if it is a transformer rated at a nominal 12VAC output, (or even an adapter

Get a quote

How bad, if at all, is 14.4V overvoltage for 12V inverter?

In general, 12v inverters will be ok with automotive voltages which can go up past 14.4volts. But you should always check the inverter (or any equipment) for their input voltage

Get a quote

How to convert 14.8V @ 10A Lipo battery output to

Since the cutoff voltage for 14.8V battery is 12.8V, the dc-dc converter is expected to regulate 12V even when the input voltage is

Get a quote

Can One 12 Volt Battery Run a 1000 Watt Inverter?

Yes, a single 12-volt battery can run a 1000-watt inverter, but the runtime depends on several factors such as the battery''s capacity, the inverter''s efficiency, and the load

Get a quote

Circuit to convert 14.8v battery with max 4a discharge current into 12v

The best option I have found is using 3 step down buck converter modules. But is there a way to combine 3 separate buck converters to reduce the size of the PCB to as small

Get a quote

6 FAQs about [Can a 12v inverter be used to convert 14 8v to ]

What voltage should a 12V inverter run on?

The input voltage of the inverter should match the battery voltage. (For example 12v battery for 12v inverter, 24v battery for 24v inverter and 48v battery for 48v inverter Summary What Will An Inverter Run & For How Long?

Can a 4S pack run a 12V inverter?

There really isn't a good setup for that type to run a 12V inverter. 3 cells is just too low a nominal voltage, and 4 is too high. LiFeP04, tho, are almost perfect. a 4S pack has a fully charged voltage of 14.4-14.6, and a fully discharged voltage of 10 or so. That's perfect for most any 12V inverter out there.

Do I need a 12V or 48V inverter?

Simply put, if you have a 12V system, you need a 12V inverter; a 48V system requires a 48V inverter. Standard Pure Sine Wave inverters simply change DC power to AC power. Inverter Chargers handle this function plus allow you to charge your batteries off shore power or a generator. Renogy’s 3500W Solar Inverter Charger is designed for a 48V system.

How much battery do I need to run a 3000-watt inverter?

You would need around 24v 150Ah Lithium or 24v 300Ah Lead-acid Battery to run a 3000-watt inverter for 1 hour at its full capacity Here's a battery size chart for any size inverter with 1 hour of load runtime Note! The input voltage of the inverter should match the battery voltage.

Are LiFeP04 12V inverters reliable?

LiFeP04, tho, are almost perfect. a 4S pack has a fully charged voltage of 14.4-14.6, and a fully discharged voltage of 10 or so. That's perfect for most any 12V inverter out there. I've seen many Amazon 'replies' that haven't been very reliable. My little sinewave inverter loves my LiFeP04 12V packs!

What if my inverter is not running at its full capacity?

If you're not running your inverter at its full capacity, For Example, let's say you have a 1000W inverter but your daily total load at a time doesn't exceed 600 AC watts so instead of entering 1000 in the inverter size box you can enter 600 which will give a battery size according to your load

Guess what you want to know

-

How many hours can a home inverter convert 12v to 220v be used for

How many hours can a home inverter convert 12v to 220v be used for

-

Can the 14 8V battery be used with the inverter

Can the 14 8V battery be used with the inverter

-

Buy an inverter to convert 12v to 9v

Buy an inverter to convert 12v to 9v

-

Can solar panels and 12v water pump inverter be used together

Can solar panels and 12v water pump inverter be used together

-

Canadian lead-acid lithium battery universal 12v inverter

Canadian lead-acid lithium battery universal 12v inverter

-

12v inverter motor

12v inverter motor

-

Solar Panel 12V 24V Universal Inverter

Solar Panel 12V 24V Universal Inverter

-

12V to 3kW inverter

12V to 3kW inverter

-

220v to 13 8v voltage stabilizing inverter

220v to 13 8v voltage stabilizing inverter

-

Inverter 12v live charging

Inverter 12v live charging

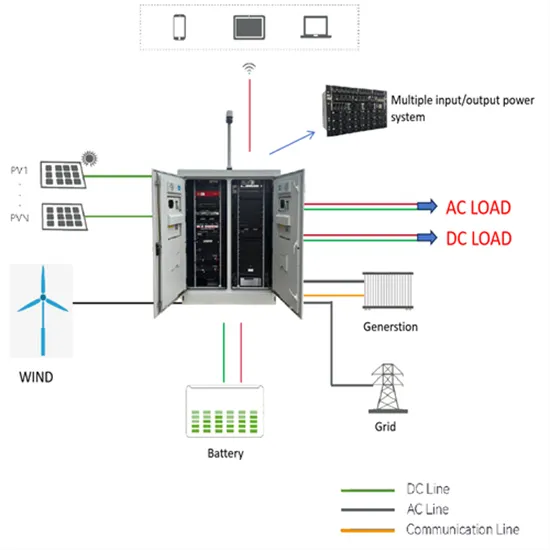

Industrial & Commercial Energy Storage Market Growth

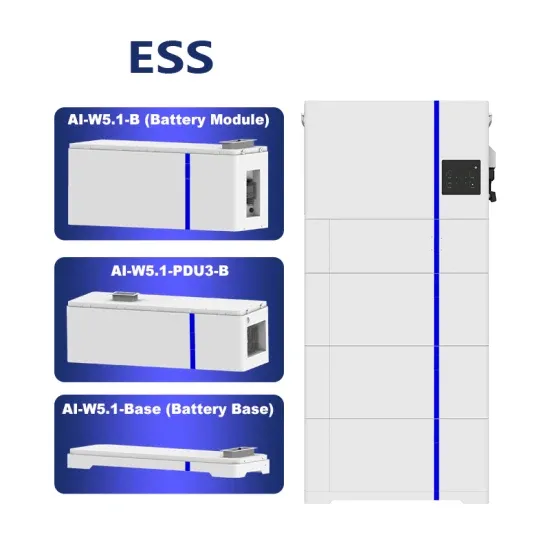

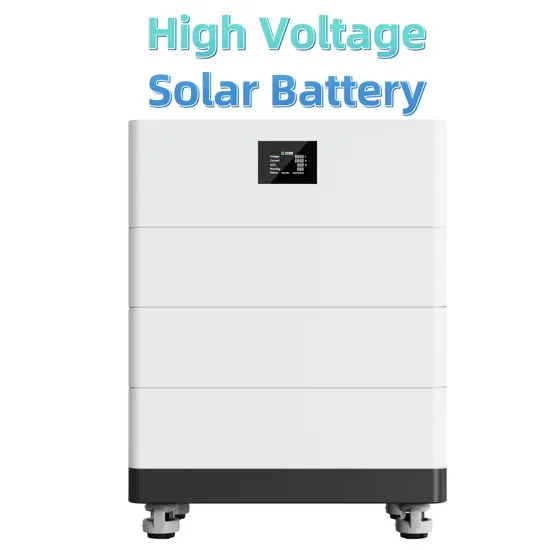

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

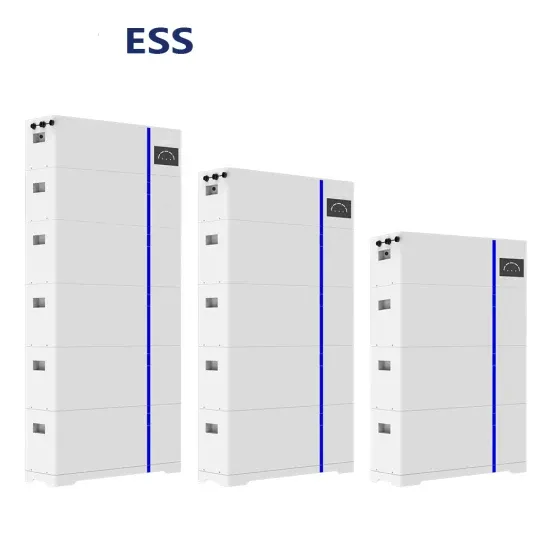

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.