Balancing performance and manufacturability in battery cooling plates

Every advancement in liquid cooling plate technology is backed by a systematic understanding of application scenarios, material properties, and manufacturing processes.

Get a quote

Types of Cold Plates Used In The New Energy Sector

Explore the main types of cold plates used in the new energy sector. Learn design methods, applications, and selection tips for optimal cooling.

Get a quote

Designing a Battery Cooling Plate: Strategies & Innovations

This article will focus on EV battery cooling plates and cold plate design. Proper thermal management systems are required to prevent excessive heating during speed charges or

Get a quote

Cold plate manufacturing challenges? FSW solves

The cold plate manufacturing industry is continuously advancing, prioritizing efficiency and innovation. However, even with these advancements, the sector

Get a quote

COLD PLATES | Thermovac Aerospace Pvt. Ltd.

Most often these liquid cold plates are made of aluminium. Thermovac liquid cold plates are the best choice for cooling high-powered electronics, IGBT

Get a quote

Electric Vehicle Liquid Cold Plate Case Study

When creating a new series of batteries for electric vehicles (EVs), a leading battery producer approached Boyd to design new liquid cold plates for the

Get a quote

Battery Cold Plate

Built with lightweight aluminum, the battery cold plate stabilizes battery cell temperature and provides optimal temperature uniformity. Featuring counterflow and double-side cell loading

Get a quote

Trumony Aluminum Limited: A Leading Force in Battery Cold Plate

Conclusion: A Strategic Partner in the Future of Battery Thermal Management As global demand for advanced battery solutions accelerates, Trumony Aluminum Limited

Get a quote

Designing battery cold plates through generative design

This paper explains the fundaments of topology optimization for battery cold plates and illustrates the added value of the method through multiple examples and comparisons.

Get a quote

Which process improvements have the greatest impact on cost

Discover proven strategies for reducing production costs in battery liquid cold plate manufacturing. This overview covers everything from material selection and design optimization to integrated

Get a quote

(PDF) A novel cold plate design for liquid-based battery thermal

A novel cold plate design for liquid-based battery thermal management through multi objective topology optimization October 2024

Get a quote

A comprehensive numerical study based on topology optimization

TL;DR: This study applies topology optimization to design cooling plates for battery packs, demonstrating improved heat dissipation performance at low flow rates, with a 3.5 K

Get a quote

Balancing performance and manufacturability in

Every advancement in liquid cooling plate technology is backed by a systematic understanding of application scenarios, material properties, and

Get a quote

Designing battery cold plates through generative design

This paper explains the fundaments of topology optimization for battery cold plates and illustrates the added value of the method through multiple

Get a quote

Technical requirements for battery cabinet cold plate welding

Thermal can provide a variety of liquid cold plate production processes, including friction stir welding, profile water-cooled plate processing, brazing technology, and copper tube

Get a quote

Liquid Cooling Plate – XD Thermal

XD THERMAL''s liquid cooling plates are designed to meet the increasing demand for efficient thermal management in lithium battery packs used in EVs, ESS, and beyond. By leveraging

Get a quote

How Cold Plates Control Battery "Body Temperature" in EVs

Liquid and direct cooling plates—learn how these key components keep EV batteries at the perfect "body temperature" for safety and power.

Get a quote

Cold Plates

Alkraft''s Cold Plates are designed to provide consistent cooling, ensuring temperature uniformity throughout the battery surface. This uniform cooling is essential for maintaining battery

Get a quote

Battery Pack Cooling Solutions: Liquid Cold Plates Explained

Discover how liquid cold plates improve battery pack thermal management with better cooling performance, safety, and system efficiency.

Get a quote

Energy storage liquid cooling cabinet manufacturing

Main products: Coolinside liquid-cooled cabinet and full chain liquid cooling solution, BattCool energy storage full chain liquid cooling solution 2.0, XGlacier full chain cold plate liquid cooling

Get a quote

EV Battery Cooling Plates

The Sogefi hybrid cold plate composed of welded metal/plastic composite is another innovative solution for improved impact resistance and intregration with composite battery pack enclosures.

Get a quote

Guess what you want to know

-

What are the battery cabinet production equipment

What are the battery cabinet production equipment

-

Battery cabinet production and design outdoor site

Battery cabinet production and design outdoor site

-

Battery Cabinet Production Notes

Battery Cabinet Production Notes

-

Energy storage cabinet inverter battery production battery

Energy storage cabinet inverter battery production battery

-

Battery cabinet system production

Battery cabinet system production

-

Does battery cabinet production consume energy

Does battery cabinet production consume energy

-

Energy storage cabinet battery original 125kWh production

Energy storage cabinet battery original 125kWh production

-

Battery cabinet 125kWh production

Battery cabinet 125kWh production

-

Battery cabinet production process base station

Battery cabinet production process base station

-

Authentic energy storage cabinet battery production base

Authentic energy storage cabinet battery production base

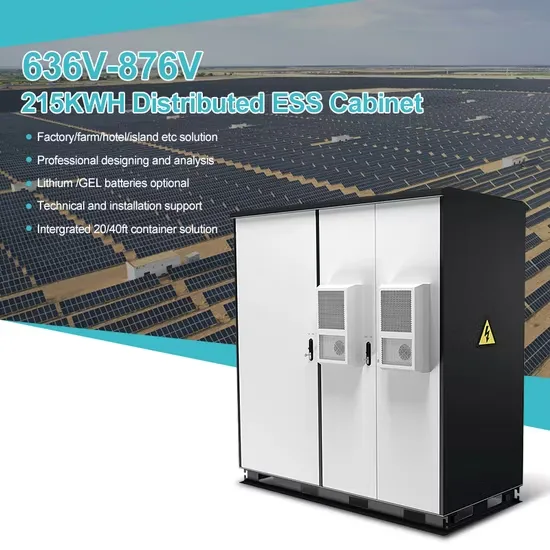

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.