Inverter Cable Size Calculator & Formula Online Calculator Ultra

Importance and Usage Scenarios This tool is particularly important in solar power setups, RV installations, and other systems where inverters are used. Proper cable sizing

Get a quote

12V vs 24V Inverter: What''s The Difference & Which is Better

Torn between 12V and 24V inverters? Discover the key differences in efficiency, cost, and power capacity to determine which is better for your energy needs.

Get a quote

How Much Power an Inverter Draws with No Load

In simple terms, inverter efficiency refers to how well an inverter converts DC electricity into usable AC power. No inverter is 100% efficient—some energy always gets lost

Get a quote

12V Inverter vs 24V Inverter — What Is The Difference & Which

This article will explore the differences between 12v inverter vs 24v inverter, considering factors such as energy loss, battery requirements, and suitability for different

Get a quote

How Much Power Does An Inverter Draw With No Load?

Power drawn = 24V * 0.4 = 9.6 watts. This formula and calculation are applicable to all inverters irrespective of their size. 12V or 24V is the only thing that will make the

Get a quote

24V Battery Duration with Inverter: Key Factors for 1000W and

Inverter efficiency refers to the percentage of input power that is converted to usable output power. Most inverters have an efficiency range of 85-95%. This means that if

Get a quote

48V Inverter: The Ultimate Guide to Efficient and Scalable Power

Unlock efficient power solutions with a 48V inverter—perfect for solar, off-grid, and backup systems. Learn how to choose the best one for your needs now!

Get a quote

How to Reduce DC to AC Inverter Losses & Boost

Car inverters are usually designed to be used in 12V or 24V low voltage systems, and connecting them directly to 110V appliances may cause

Get a quote

Calculate Battery Size for Inverter Calculator

The Calculate Battery Size for Inverter Calculator helps you determine the optimal battery capacity needed to support your inverter system. By inputting critical parameters such

Get a quote

Inverter Calculator

In order to ensure that the capacity of your power inverter is sufficient to meet the required start up load, you must first determine the power consumption of the equipment or appliance you plan

Get a quote

How Much Power Does An Inverter Draw With No Load?

Power drawn = 24V * 0.4 = 9.6 watts. This formula and calculation are applicable to all inverters irrespective of their size. 12V or 24V is the only

Get a quote

The 3 Most Common Faults on Inverters and how to Fix Them

At IDS we have a wealth of inverter experience. We have been an ABB Partner for over 20 years and are used to supporting clients with a variety of inverter-controlled applications. In this

Get a quote

SolarEdge System Design and the NEC

Heat Generation of Inverters The sources of heat in the inverter are the same mechanisms that determine the inverter efficiency. All the efficiency losses of the inverter are converted into

Get a quote

Inverter Calculator

In order to ensure that the capacity of your power inverter is sufficient to meet the required start up load, you must first determine the power consumption of the

Get a quote

How Much Power an Inverter Draws with No Load

To find out how much power an inverter draws without any load, multiply the battery voltage by the inverter no load current draw. A 1000 watt 24V inverter with a 0.4 no load current has a

Get a quote

Calculate Battery Size For Any Size Inverter (Using

Battery size chart for inverter Note! The input voltage of the inverter should match the battery voltage. (For example 12v battery for 12v inverter,

Get a quote

How long will an inverter run off a battery? – ANENJI

Key Factors Affecting Inverter Runtime Before estimating how long a battery can power an inverter, it is important to understand several key factors that directly determine the

Get a quote

What percentage of losses occur in conversion from DC to AC?

Expected losses are in the 5-15% range, but many inverters are less efficient when operated at low power. While the panels may be capable of supplying a certain amount of

Get a quote

Pros and Cons of 24V Solar Panels: A Comprehensive Guide by

Explore the pros and cons of 24V solar panels with Voltset. Learn about their advantages, limitations, and ideal applications to decide if they''re the perfect fit for your solar

Get a quote

How to Reduce DC to AC Inverter Losses & Boost Efficiency?

Car inverters are usually designed to be used in 12V or 24V low voltage systems, and connecting them directly to 110V appliances may cause the device to burn out.

Get a quote

Inverter Efficiency: Understanding How Much Power You''re

In simple terms, inverter efficiency refers to how well an inverter converts DC electricity into usable AC power. No inverter is 100% efficient—some energy always gets lost

Get a quote

12V vs 24V vs 48V Inverter: How to Choose the Right System for

Confused about choosing between 12V, 24V, or 48V inverter systems? Discover which voltage is best for RV, solar, and off-grid setups. Learn the pros, cons, efficiency, cable

Get a quote

What''s a better plan, 24v direct or 24v inverted to 110v? Similar to

There''s always an efficiency loss going from DC -> AC -> DC. So you will always get better performance running DC loads directly from the battery when it makes sense. You

Get a quote

How much power does an Inverter use just sitting there idling?

In the tech data, I''m supposed to give the inverter a "few seconds" before applying a load, so you could probably figure a way to do that. I''m sure applying the load while

Get a quote

How Long Will a 2000 Watt Inverter Run? Battery

A 2000 watt inverter is a versatile power solution, commonly used for RVs, off-grid solar systems, and emergency backup power. However,

Get a quote

6 FAQs about [How much is the loss of 24V inverter ]

How much power does a solar inverter lose?

Expected losses are in the 5-15% range, but many inverters are less efficient when operated at low power. While the panels may be capable of supplying a certain amount of power, this doesn't matter until there is sufficient load to consume that power.

How much power does a 24V inverter draw?

To find out how much power an inverter draws without any load, multiply the battery voltage by the inverter no load current draw. A 1000 watt 24V inverter with a 0.4 no load current has a power consumption of 9.6 watts. 24V x 0.4 = 9.6 watts If you want to figure out the no load current in amps, divide the watts consumption by the battery voltage.

How long does a 24V inverter last?

An inverter draws its power from the battery so the battery capacity and power load determines how long the inverter will last. Regardless of the size, the calculation steps are always the same. Using this calculation, a 24V inverter with a 100ah battery and 93% efficiency can run a 500W load for 2.3 hours.

What happens if a solar inverter draws too much power?

This is because if too much current is drawn from the panels, the voltage begins to drop. So the inverter tries to find a load that maximizes the power (Volts * Amps) from the panels but only if the inverter requires the power.

How much power does an inverter use?

The more modern the inverter, the more power you save. A 90% efficient inverter means it requires 10% more power than what its load requires. If you run a 300 watt load for instance, the inverter will need 330 watts. With larger inverters the drain could be up to 2 amps even a load.

What is inverter no load current?

The inverter no load current should not be confused with inverter efficiency, which determines how much power is converted by the system. In an off grid system, the inverter transforms DC into AC power so that it is compatible with home appliances. Some of the power will be lost during the conversion, though the amount varies.

Guess what you want to know

-

How much does a 24v 3kw industrial frequency inverter weigh

How much does a 24v 3kw industrial frequency inverter weigh

-

How big an inverter should I use for a 24v electric winch

How big an inverter should I use for a 24v electric winch

-

How much loss does a lithium battery inverter have

How much loss does a lithium battery inverter have

-

How much does a 24V 10 000W inverter cost

How much does a 24V 10 000W inverter cost

-

How many Ah batteries are suitable for a 24v 3kw inverter

How many Ah batteries are suitable for a 24v 3kw inverter

-

How much loss does the inverter have when charging lithium batteries

How much loss does the inverter have when charging lithium batteries

-

How many watts does a 24v 220v inverter produce

How many watts does a 24v 220v inverter produce

-

How big a battery is needed for a 24v 3000 inverter

How big a battery is needed for a 24v 3000 inverter

-

Where can I find a 24V inverter in Huijue

Where can I find a 24V inverter in Huijue

-

How much does a 12v inverter generate at 650v

How much does a 12v inverter generate at 650v

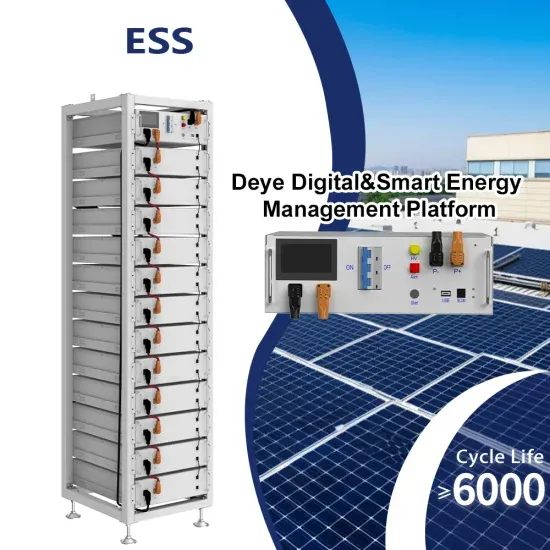

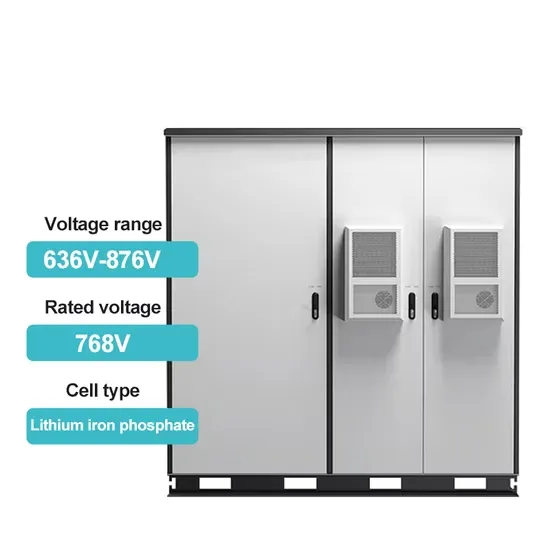

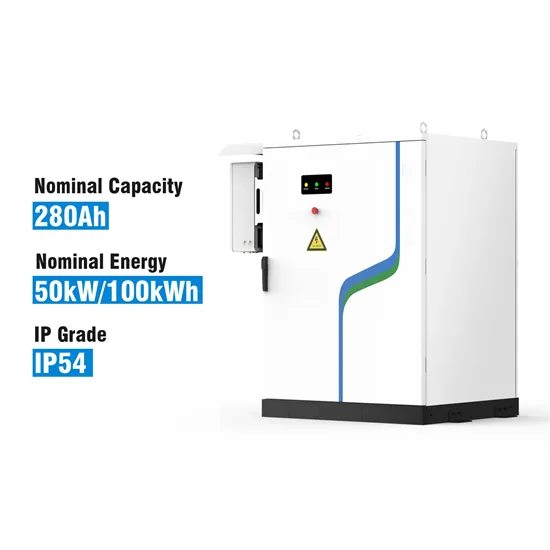

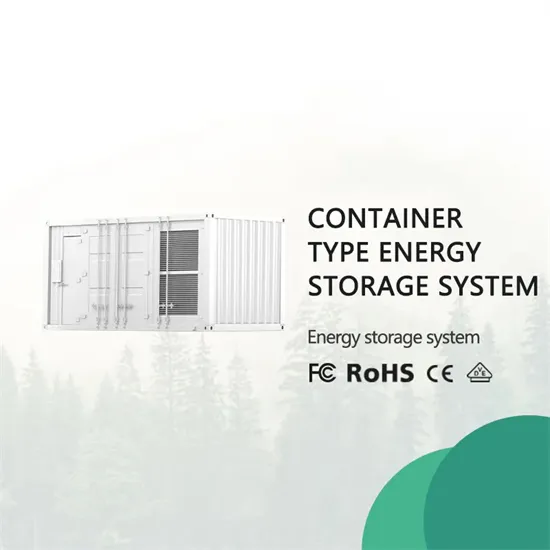

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.