How to Check DC Internal Resistance with A Multimeter

To measure DC internal resistance with a multimeter, you first measure the unloaded voltage of the battery (v1), then the voltage under load (v2), and finally the resistance

Get a quote

Internal Resistance of a Battery: How to Measure It

There are several methods used to measure the internal resistance of a battery. Each method has its advantages and limitations. Let''s

Get a quote

How to Check DC Internal Resistance with A Multimeter

For voltage measurements, especially in high-impedance circuits (e.g., sensors, control circuits, vacuum tube circuits, or battery testing where the battery''s internal resistance

Get a quote

BU-902: How to Measure Internal Resistance

Before exploring the different methods of measuring the internal resistance of a battery, let''s examine what electrical resistance means and understand the

Get a quote

How to make Battery Internal Resistance Meter with

Here is the complete explanation of how to build a Battery Internal Resistance Meter with Arduino and Atmel ATtiny85 IC. This Internal

Get a quote

Lithium-ion Battery Internal Resistance Testing

There are two methods for measuring internal resistance: the AC method (AC-IR) and the DC method (DC-IR). Testing on production lines uses the AC method, which is introduced by this

Get a quote

What Is The Internal Resistance Of A Multimeter?

For voltage measurements, especially in high-impedance circuits (e.g., sensors, control circuits, vacuum tube circuits, or battery testing where the battery''s internal resistance

Get a quote

How To Measure Internal Resistance With A Multimeter

Discover a straightforward method to calculate the internal resistance of lithium-ion batteries using a multimeter. Learn how to assess

Get a quote

Chapter 42 Circuit Testers and Digital Meters

Could blow an internal fuse or damage the meter What could happen if the meter leads were connected to the positive and negative terminals of the battery while the meter and leads were

Get a quote

How To Measure Internal Resistance With A Multimeter

Discover a straightforward method to calculate the internal resistance of lithium-ion batteries using a multimeter. Learn how to assess voltage drop, current, and battery efficiency

Get a quote

The FNIRSI HRM-10 Internal Resistance Meter

We''ve touched on measuring battery internal resistance before, but it was a while ago. Regarding Kelvin connections, here''s a quick guide and a

Get a quote

FNIRSI HRM-10 Battery Internal Resistance Tester

Author Topic: FNIRSI HRM-10 Battery Internal Resistance Tester [ & Milli-Ohmmeter] Review (Read 5667 times) 0 Members and 2 Guests are viewing this topic.

Get a quote

Xtester-RC3563 High-precision Battery Internal

It can also be used to measure the AC resistance of capacitors and low-resistance high-precision resistance.RC3563 battery internal resistance

Get a quote

How to Measure Battery Internal Resistance with Multimeter?

Step-by-Step Guide: Measuring Internal Resistance with a Multimeter While multimeters can''t directly measure internal resistance, a simple load test reveals critical data.

Get a quote

Understanding Lithium Battery Internal Resistance Testing

The internal resistance of a lithium battery is also approximated using this method to determine the equivalent ohmic resistance. However, to achieve practical results with a

Get a quote

BATTERY TESTER BT3554-51 KIT – Hioki Southeast

Bundled with Z3210 and 9465-10 Probe Key features • Battery measurement can be performed while the battery is connected to its host device, without taking it

Get a quote

Troubleshooting Battery Internal Resistance Measurements

Try the experiment with one battery (cell), making contact directly to the battery without the battery holder. You mentioned that you used the same meter to measure the current.

Get a quote

Lithium-ion Battery Internal Resistance Testing

There are two methods for measuring internal resistance: the AC method (AC-IR) and the DC method (DC-IR). Testing on production lines uses the AC method,

Get a quote

Internal Resistance of a Battery: How to Measure It

There are several methods used to measure the internal resistance of a battery. Each method has its advantages and limitations. Let''s explore some of the commonly used

Get a quote

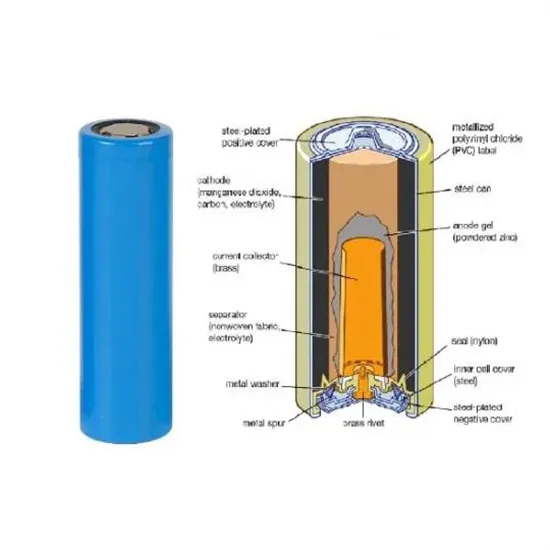

What is battery internal resistance? Accurate method of

The internal resistance of a battery is a measure of the resistance of current inside the battery, or in other words, it is the level of resistance between the two terminals of the

Get a quote

HRM-10 Battery Tester Internal Resistance Tester, Lithium Battery

Amazon : HRM-10 Battery Tester Internal Resistance Tester, Lithium Battery Internal Resistance Meter, Battery Voltage Internal Resistance Tester, Digital Battery Analyzer

Get a quote

BU-902: How to Measure Internal Resistance

Before exploring the different methods of measuring the internal resistance of a battery, let''s examine what electrical resistance means and understand the difference between pure

Get a quote

Measuring Internal Resistance of Batteries

Available online at: Contents Introduction Internal Resistance Build a Voltmeter Build a Lemon Battery Take Voltage Measurements Calculate the Internal Resistance

Get a quote

How To Test Battery Resistance With Multimeter? A Step-by

One crucial aspect of battery health assessment is measuring internal resistance. This measurement provides valuable insights into a battery''s overall condition, its ability to

Get a quote

Lipo ESR Meter Mark II Lipo power battery analyzer

The ESR (Equivalent Series Resistance) meter gives you just that ability - powered by the battery itself, the meter provides the internal resistance of an entire pack to a resolution of 0.3

Get a quote

What Is The Internal Resistance Of A Multimeter?

Understanding Internal Resistance: The Fundamental Concept The term internal resistance, when applied to a multimeter, refers to the inherent resistance within the

Get a quote

BATTERY HiTESTER BT3564

Hioki benchtop battery testers support simultaneous high-speed measurement of the internal resistance and battery voltage of EV and PHEV battery packs. The BT3564 Battery HiTester

Get a quote

HT3561 Economic Battery Internal Resistance Tester

The HT3561-12H/24H multi-channel battery tester can quickly complete the internal resistance and voltage sorting test of the maximum 24-channel

Get a quote

6 FAQs about [The internal resistance meter probe hits the battery cabinet]

How to measure battery internal resistance?

The pulse load test is another method for measuring battery internal resistance. It involves applying a short-duration, high-current pulse to the battery and measuring the voltage response. The internal resistance can be calculated from the voltage drop during the pulse. 1.

How to measure DC internal resistance with a multimeter?

To measure DC internal resistance with a multimeter, you first measure the unloaded voltage of the battery (v1), then the voltage under load (v2), and finally the resistance of the load (r1), which allows you to calculate the internal resistance using ISR = (V1 - V2)/ (V2/R1).

How does a resistance meter measure a battery?

AC resistance meters apply a constant-current AC signal to the battery. They then detect the minuscule voltage generated by the current and calculate the resistance value. Note that DC resistance meters cannot measure batteries, which have non-zero voltage or electromotive force. Measurement method varies depending on the equipment configuration.

Which method is used to measure internal resistance?

There are two methods for measuring internal resistance: the AC method (AC-IR) and the DC method (DC-IR). Testing on production lines uses the AC method, which is introduced by this article.

How do you measure internal resistance?

The most accurate way to measure internal resistance is by using a dedicated battery tester like the Hioki BT3554, Megger BITE3, or Fluke 500 Series. These devices use AC impedance testing to provide precise readings without significantly discharging the battery. Steps: Turn on the tester and set it to internal resistance mode.

How do you test a battery with a multimeter?

Measure the Unloaded Voltage: Measure the voltage of the battery when it is not connected to any load. Note this voltage as V1. Measure the Load's Resistance: Switch the multimeter to resistance and measure the resistance of the load that you are going to use to test the battery. Note this value as R1.

Guess what you want to know

-

Lithium battery internal energy storage cabinet price

Lithium battery internal energy storage cabinet price

-

What is the internal connection technology of the battery cabinet

What is the internal connection technology of the battery cabinet

-

What is the price of the matching battery cabinet

What is the price of the matching battery cabinet

-

How much electricity does a 300w outdoor battery cabinet generate

How much electricity does a 300w outdoor battery cabinet generate

-

New Energy Battery Cabinet Brand Introduction

New Energy Battery Cabinet Brand Introduction

-

Which outdoor communication battery cabinet is the best and most durable in Mauritius

Which outdoor communication battery cabinet is the best and most durable in Mauritius

-

Air-cooled energy storage cabinet battery module site communication

Air-cooled energy storage cabinet battery module site communication

-

Energy storage cabinet battery current and voltage are high

Energy storage cabinet battery current and voltage are high

-

How much does it cost to replace the 37 degree battery cabinet

How much does it cost to replace the 37 degree battery cabinet

-

Who are the Cuban outdoor communication battery cabinet manufacturers

Who are the Cuban outdoor communication battery cabinet manufacturers

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.