Container Handling Equipment

Konecranes is a major global player in the design, manufacture and servicing of container handling equipment. Excellent technology isn''t enough in itself – build quality, delivery

Get a quote

Base Station Container CL-400 | Conlog Oy | Finland

The container was built with advanced ballistic protection that is integrated into the structure in such a way that the weight of the container remains as low as possible. The Base Station

Get a quote

Deployable infrastructure | Containerised solutions

Base platforms are available in 10ft, 20ft or expandable sizes and come with a catalogue of options to allow easy configuration in line with budget and operational requirements.

Get a quote

Bulk Container Filling Equipment, Tote Fillers, Box

For applications requiring handling and filling of different container types within the same fill station, NBE bulk container filler bases are engineered to ensure

Get a quote

Container Handling Equipment

Unmanned, automated container transport vehicles, or Automated Guided Vehicles (AGVs), which are used for rapid and economical container transport between the quayside and the

Get a quote

Shipping Container Foundations: Complete Guide to Choose the Right Base

Learn when a shipping container needs a foundation, explore 10 types, and get expert tips to choose the right base for your container project.

Get a quote

SUMMIT BASE CONTAINER

Since 2011 the Summit has set the standard for BASE container design. Many of the Summit''s features and design elements have found their way into other models being built around the

Get a quote

Top Container Handling Equipment for All-Scale Operations

Discover reliable container handling equipment for small to large-scale operations, ensuring efficiency, safety, and productivity in logistics.

Get a quote

Chapter 6.5 – Container Terminal Design and Equipment

A container terminal relies on an array of intermodal equipment to perform its operations, including straddle carriers, gantry cranes, and portainers (ship-to-shore cranes).

Get a quote

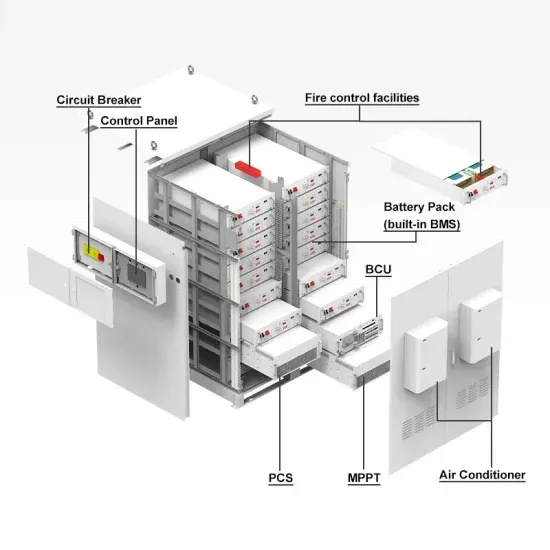

The BESS System: Construction, Commissioning, and

A comprehensive guide on the construction, commissioning, and operation & maintenance of industrial and commercial energy storage systems.

Get a quote

Shipping Container Foundations: Complete Guide to

Learn when a shipping container needs a foundation, explore 10 types, and get expert tips to choose the right base for your container project.

Get a quote

Deployable infrastructure | Containerised solutions

Base platforms are available in 10ft, 20ft or expandable sizes and come with a catalogue of options to allow easy configuration in line with budget and

Get a quote

Top Container Handling Equipment for All-Scale

Discover reliable container handling equipment for small to large-scale operations, ensuring efficiency, safety, and productivity in logistics.

Get a quote

Base Station Container CL-400 | Conlog Oy | Finland

The container was built with advanced ballistic protection that is integrated into the structure in such a way that the weight of the container remains as low as

Get a quote

Containerized Battery Energy Storage System

Discover the benefits and features of Containerized Battery Energy Storage Systems (BESS). Learn how these solutions provide efficient,

Get a quote

Genesis Sterilization Containers | STERIS

Genesis™ Sterilization Containers The Genesis™ container systems are designed to achieve and maintain the sterility of your surgical instruments. We

Get a quote

Waste collection – Storage containers and collection

In this type of collection system, the waste containers are hauled to discharge the waste directly to the transfer station, material recovery facility or disposal site.

Get a quote

Chapter 6.5 – Container Terminal Design and Equipment

Container terminal. A terminal facility specializing in the transshipment, handling, and temporary storage of containers between at least two transportation modes. They have a footprint

Get a quote

GPS and GNSS receivers, bases and rovers for positioning

GPS or GNSS receivers for base and rover setup. Ideal for survey applications, construction site layout/stakeout, grade checking, material volume calculations, and base stations.

Get a quote

Base Stations and Cell Towers: The Pillars of Mobile

Base stations and cell towers are critical components of cellular communication systems, serving as the infrastructure that supports seamless

Get a quote

Bulk Container Filling Equipment, Tote Fillers, Box Fillers

For applications requiring handling and filling of different container types within the same fill station, NBE bulk container filler bases are engineered to ensure safe, accurate, and effective

Get a quote

Custom Mix-N-Load Poly Deck System | Chemical Mixing Station

Chemical Containers custom designs and builds highly versatile Mix-N-Load Poly Deck Systems that provide a chemical mixing station and truck loading system all in one place.

Get a quote

PEO CS&CSS: Product Manager Force Sustainment

The Force Provider Module has evolved from a 550 Soldier camp with limited flexibility in deployment capability into an Expeditionary Base

Get a quote

6 FAQs about [Base station equipment for container system]

What equipment does a container terminal use?

A container terminal relies on an array of intermodal equipment to perform its operations, including straddle carriers, gantry cranes, and portainers (ship-to-shore cranes). The choice of equipment and its mix is influenced by several factors, including capital investment, volume, stacking density, and productivity. Forklift.

What is the best container lifting system for small operations?

Small operations would be well served with compact solutions, such as shipping container dollies or container lifting jacks, to ensure an easy and affordable handling process. Large operations require heavy-duty solutions, including crane systems or the versatile HitchWich System for seamless container movement.

What are NBE bulk container filling systems?

The materials of construction and build specifications of NBE bulk container filling systems enable bulk material processing operations to maintain designed line speeds without concern for unplanned downtime, over- or under-filled containers, or excess labor required for rework.

How does a container terminal system work?

Terminal equipment is combined to form an integrated container terminal system. The total terminal capacity is determined by the interaction between three levels, which are the quay, the yard, and the gate system:

What are NBE bulk bag filler bases?

NBE bulk bag filler bases receive, and can densify, a single container, or multiple containers at one time on slipsheets or pallets. NBE bulk bag filling systems easily integrate with NBE indexing and accumulation conveyors, improving upstream and downstream process performance.

What is a container terminal?

Container terminal. A terminal facility specializing in the transshipment, handling, and temporary storage of containers between at least two transportation modes. They have a footprint including quays, yard areas, equipment such as cranes and other support facilities, including administrative and maintenance buildings and warehouses. 1.

Guess what you want to know

-

Base station equipment for container system

Base station equipment for container system

-

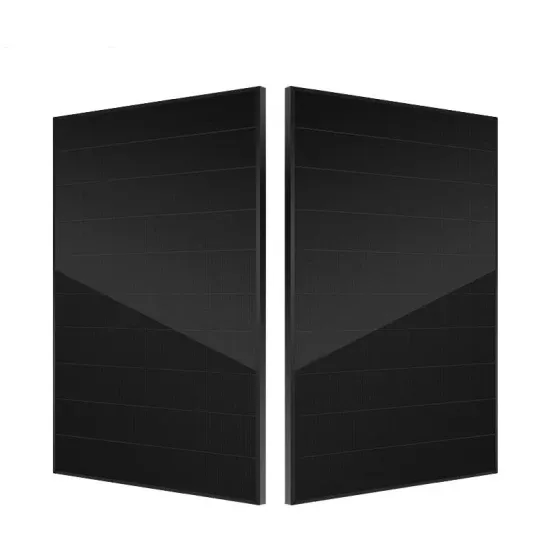

China Solar Container Base Station Photothermal Equipment

China Solar Container Base Station Photothermal Equipment

-

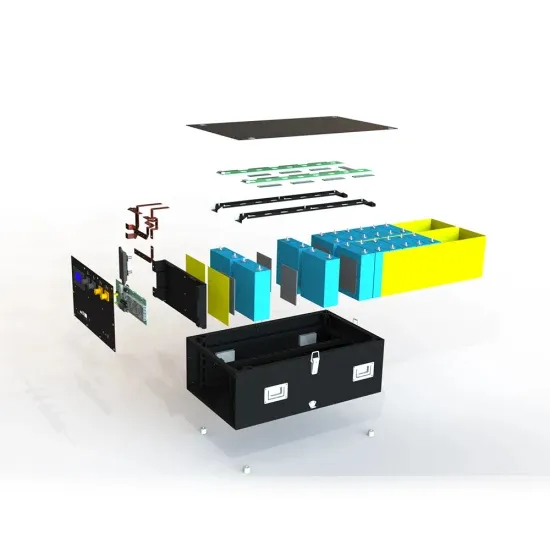

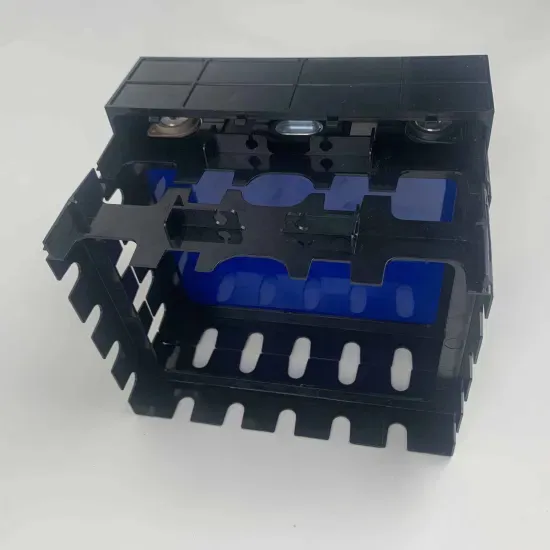

Energy Storage Container Structure Base Station

Energy Storage Container Structure Base Station

-

5g base station single-mode communication equipment

5g base station single-mode communication equipment

-

Norway communication base station energy storage equipment processing

Norway communication base station energy storage equipment processing

-

Communication system equipment base station

Communication system equipment base station

-

What is the square shape of base station communication equipment

What is the square shape of base station communication equipment

-

Communication base station solar energy storage equipment supplier

Communication base station solar energy storage equipment supplier

-

Nepal battery price container base station

Nepal battery price container base station

-

Solar Antifreeze Container ESS Power Base Station

Solar Antifreeze Container ESS Power Base Station

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.