Fundamentals of superconducting magnetic energy storage systems

Structure of an SMES system. A standard SMES system is composed of four elements: a power conditioning system, a superconducting coil magnet, a cryogenic system

Get a quote

Superconducting magnetic energy storage

The main components of superconducting magnetic energy storage systems (SMES) include superconducting energy storage magnets, cryogenic systems, power electronic converter

Get a quote

Comprehensive review of energy storage systems technologies,

Battery, flywheel energy storage, super capacitor, and superconducting magnetic energy storage are technically feasible for use in distribution networks. With an energy density

Get a quote

Introduction to Superconducting Magnetic Energy

The article provides a detailed overview of components, such as superconducting materials like Niobium-titanium and Yttrium Barium Copper Oxide, and

Get a quote

WHAT ARE THE COMPONENTS OF A SUPERCONDUCTING MAGNETIC ENERGY STORAGE SYSTEM

An energy storage system consists of three main components:a power conversion system, which transforms electrical energy into another form of energy and vice versa;a storage unit, which

Get a quote

Superconducting magnetic energy storage

The main components of superconducting magnetic energy storage systems (SMES) include superconducting energy storage magnets, cryogenic systems,

Get a quote

Superconducting Magnetic Energy Storage: 2021 Guide | Linquip

Superconducting Magnetic Energy Storage is a new technology that stores power from the grid in the magnetic field of a superconducting wire coil with a near-zero energy loss.

Get a quote

Superconducting magnetic energy storage systems: Prospects

SMES system components are identified and discussed together with control strategies and power electronic interfaces for SMES systems for renewable energy system

Get a quote

Superconducting magnetic energy storage

OverviewAdvantages over other energy storage methodsCurrent useSystem architectureWorking principleSolenoid versus toroidLow-temperature versus high-temperature superconductorsCost

Superconducting magnetic energy storage (SMES) systems store energy in the magnetic field created by the flow of direct current in a superconducting coil that has been cryogenically cooled to a temperature below its superconducting critical temperature. This use of superconducting coils to store magnetic energy was invented by M. Ferrier in 1970. A typical SMES system includes three parts: superconducting coil, power conditioning system a

Get a quote

What is Superconducting Energy Storage Technology?

A standard SMES system comprises a vacuum-insulated cryogenic chamber that houses the superconducting coil, a cooling system (using liquid helium or nitrogen), a power

Get a quote

Superconducting magnetic energy storage

Superconducting magnetic energy storage (SMES) systems store energy in the magnetic field created by the flow of direct current in a superconducting coil that has been cryogenically

Get a quote

Modeling and exergy analysis of an integrated cryogenic

Superconducting magnetic energy storage (SMES) systems widely used in various fields of power grids over the last two decades. In this study, a thyristor-based power

Get a quote

Superconducting Magnetic Energy Storage: Principles and

Superconducting Magnetic Energy Storage (SMES) systems consist of four main components such as energy storage coils, power conversion systems, low-temperature

Get a quote

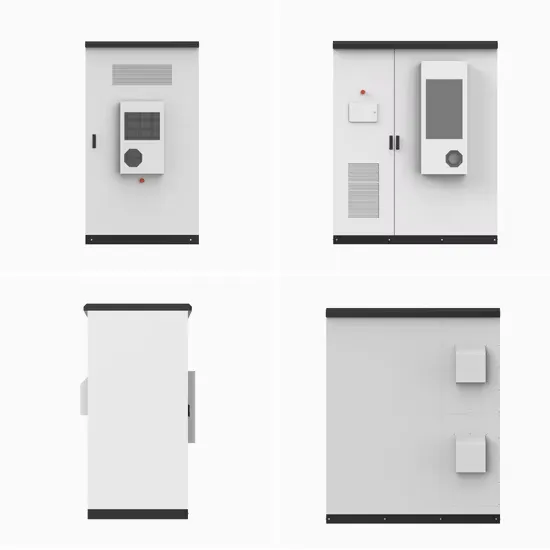

Commercial energy storage systems

In this post, we will explore each component of commercial energy storage systems in detail while highlighting their functions and importance within the

Get a quote

Superconducting magnetic energy storage systems: Prospects

This paper provides a clear and concise review on the use of superconducting magnetic energy storage (SMES) systems for renewable energy applications with the attendant challenges and

Get a quote

Application of superconducting magnetic energy storage in

Superconducting magnetic energy storage (SMES) is known to be an excellent high-efficient energy storage device. This article is focussed on various potential applications

Get a quote

WHAT ARE THE COMPONENTS OF SUPERCONDUCTING MAGNETIC ENERGY STORAGE

What are the components of an energy storage system? An energy storage system consists of three main components: a control system, which manages the energy flow between the

Get a quote

Introduction to Superconducting Magnetic Energy Storage (SMES

The article provides a detailed overview of components, such as superconducting materials like Niobium-titanium and Yttrium Barium Copper Oxide, and important design considerations for

Get a quote

Superconducting Magnetic Energy Storage: 2021

Superconducting Magnetic Energy Storage is a new technology that stores power from the grid in the magnetic field of a superconducting wire

Get a quote

Superconducting magnetic energy storage-definition, working

In this article, we will introduce superconducting magnetic energy storage from various aspects including working principle, pros and cons, application scenarios, challenges, development,

Get a quote

Superconducting magnetic energy storage-definition,

In this article, we will introduce superconducting magnetic energy storage from various aspects including working principle, pros and cons, application

Get a quote

Energy Storage System Guide for Compliance with Safety

Under the Energy Storage Safety Strategic Plan, developed with the support of the Department of Energy''s Office of Electricity Delivery and Energy Reliability Energy Storage Program by

Get a quote

What does the superconducting energy storage system include?

The superconducting energy storage system comprises several key components that enable its functionality, specifically 1. superconducting materials, 2. cryogenic systems, 3.

Get a quote

Advancements in large-scale energy storage

This special issue encompasses a collection of eight scholarly articles that address various aspects of large-scale energy storage. The

Get a quote

6 FAQs about [What are the components of a superconducting energy storage system ]

What are the components of superconducting magnetic energy storage systems (SMEs)?

The main components of superconducting magnetic energy storage systems (SMES) include superconducting energy storage magnets, cryogenic systems, power electronic converter systems, and monitoring and protection systems.

What is superconducting magnetic energy storage?

Superconducting magnetic energy storage is mainly divided into two categories: superconducting magnetic energy storage systems (SMES) and superconducting power storage systems (UPS). SMES interacts directly with the grid to store and release electrical energy for grid or other purposes.

What are the advantages of superconducting energy storage?

Superconducting energy storage has many advantages that set it apart from competing energy storage technologies: 1. High Efficiency and Longevity: As opposed to hydrogen storage systems with higher consumption rates, SMES offers more cost-effective and long-term energy storage, exceeding a 90% efficiency rating for storage energy storage solutions.

Are superconducting energy systems the future of energy?

As early as the 1960s and 70s, researchers like Boom and Peterson outlined superconducting energy systems as the future of energy due to their extremely low power losses. Over time, this vision has evolved into two main technological pathways: Superconducting Magnetic Energy Storage (SMES) and superconducting flywheel energy storage systems.

What materials are used in a superconducting system?

Superconducting materials that are commonly used are niobium-titanium, vanadium and mercury. The energy accumulated in the SMES system is released by connecting its conductive coil to an AC power converter, which is responsible for approximately 23% of heat loss for each direction.

How is energy stored in a superconducting coil?

As a result, the energy is stored in the coil in both magnetic and electric forms, and it may be recovered in a relatively short period. Ferrier invented the use of superconducting coils to store magnetic energy in 1970. The coil must be superconducting; otherwise, the energy is wasted in a few milliseconds due to the Joule effect.

Guess what you want to know

-

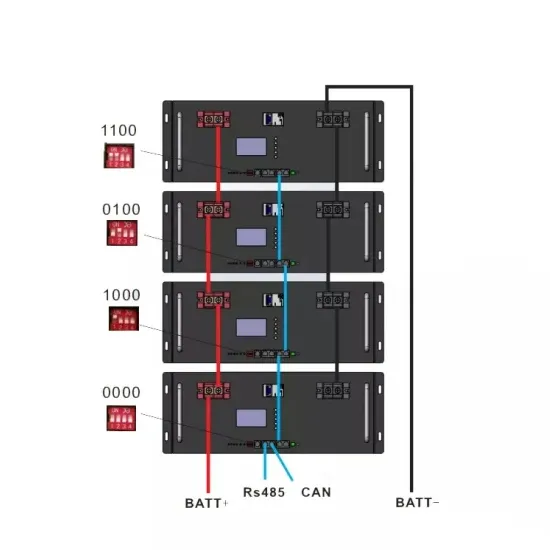

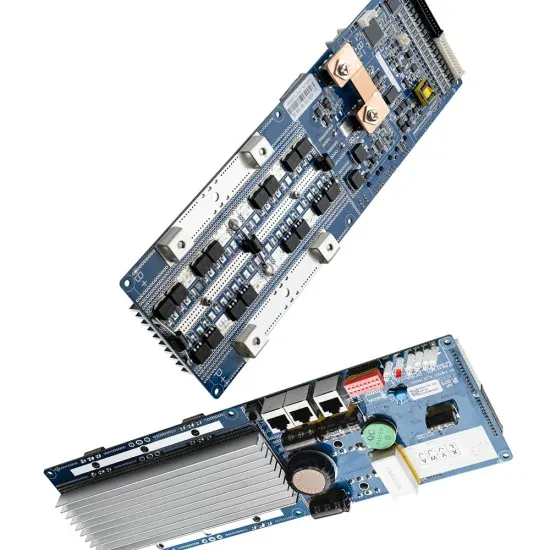

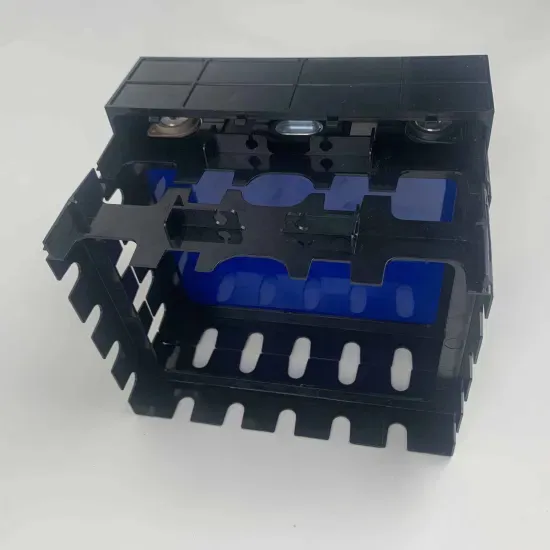

What are the components of the energy storage battery container

What are the components of the energy storage battery container

-

What are the components of a set of energy storage equipment

What are the components of a set of energy storage equipment

-

What are the components of a grid-side energy storage power station

What are the components of a grid-side energy storage power station

-

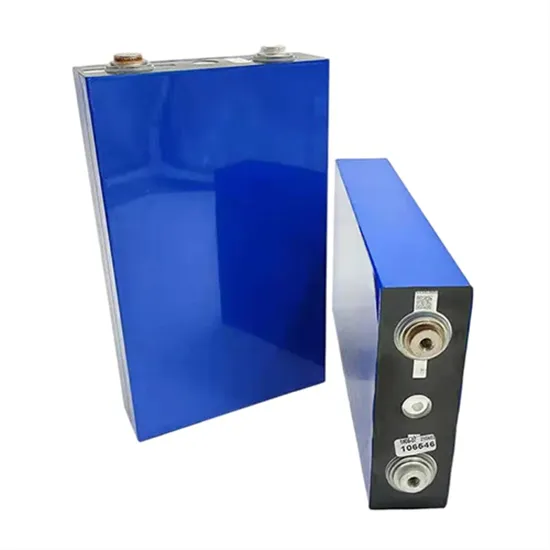

What are the commonly used battery cells for energy storage containers

What are the commonly used battery cells for energy storage containers

-

What are the energy storage photovoltaic power stations

What are the energy storage photovoltaic power stations

-

What are the brands of industrial and commercial energy storage cabinets in Swaziland

What are the brands of industrial and commercial energy storage cabinets in Swaziland

-

What is energy storage fire fighting equipment

What is energy storage fire fighting equipment

-

What are the energy storage charging stations in Vietnam

What are the energy storage charging stations in Vietnam

-

What products does the energy storage facility include

What products does the energy storage facility include

-

What is the normal energy consumption of energy storage projects

What is the normal energy consumption of energy storage projects

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.