IntraPack

–Front and back of cabinet accessible to standard material handling equipment. –Can be installed in single or multiple cabinet lineup as adjacent to each other or in a remote configuration.

Get a quote

How to Build a Battery Room for Lithium-ion, Traction,

Build a safe, efficient battery room for lead-acid, lithium-ion & EV batteries. Learn layout, ventilation & charging tips to maximise safety &

Get a quote

Explosion Proof Battery | Safety & Compliance Solutions

Safe & certified explosion-proof battery system. IECEx & ATEX compliant, ensuring reliable power & cost-effective solutions for hazardous environments.

Get a quote

IntraPack

One of the tightest footprints available. A space saving footprint saves valuable equipment room floor space. Front terminal battery system mechanical features: 4 shelf model shown, fewer

Get a quote

BATTERY CABINETS CATALOGUE

The monoblocks making up the battery are made of flame retardant material according to UL 94 class HB or V0 standards, this type of construction makes them particularly suitable for

Get a quote

Can the battery cabinet be located together with the machine

The battery room shall be located in a way that provides access for lifting equipment to be used during initial installation and future maintenance operations. Battery cabinets must enclose the

Get a quote

C & D Technologies | Stationary Battery Cabinets

C&D battery cabinets and enclosures Battery cabinet solutions for pure lead agm batteries From the industry leader in data center backup batteries, C&D now offers a configurable cabinet

Get a quote

The BESS System: Construction, Commissioning, and

A comprehensive guide on the construction, commissioning, and operation & maintenance of industrial and commercial energy storage systems.

Get a quote

battery cabinet,battery storage cabinet,battery bank rack

We can supply customized lead acid battery rack and cabinet system for solar, UPS, Telecom, Data center etc. EverExceed designs customized battery cabinets / racks for individual

Get a quote

Battery Cabinet

This manual contains information on Atlantic Battery Systems battery cabinets. The information in this manual is intended for Qualified Installers, Equipment Engineers, and Field Support

Get a quote

General requirements for the installation of UPS systems

Monitoring: Regularly check the battery system for issues and follow maintenance schedules. Safety Equipment: Have safety gear and equipment on hand in case of

Get a quote

Energy Storage Cabinet Assembly Site Design Drawing:

Ever wondered why some battery energy storage system (BESS) manufacturers complete projects 30% faster than competitors? The secret often lies in their energy storage cabinet

Get a quote

Cell Site Enclosures

Our cell site enclosure program offers flexibility in design to ensure the requirements for your site will be met. The enclosures may be used as individual stand-alone enclosures or combined on

Get a quote

Microsoft Word

The battery cabinet is equipped with narrow pallet jack or forklift access openings in the front and rear of the cabinet. Move the equipment into the desired location and set in place.

Get a quote

How to Build a Battery Room for Lithium-ion, Traction, Stationary

Build a safe, efficient battery room for lead-acid, lithium-ion & EV batteries. Learn layout, ventilation & charging tips to maximise safety & performance.

Get a quote

Lithium battery energy storage cabinet assembly

In this guide, we will introduce the correct installation steps after receiving the lithium battery energy storage cabinet, and give the key steps and precautions for accurate

Get a quote

Battery Room Safety: Swift Power''s Protection Guide

Dive into the crucial role of battery room protection within industrial facilities and warehouses. Learn how implementing safety measures not only prevents

Get a quote

UPS/DC Battery Room, Equipment Installation Requirements

This article is about Inspection and technical design requirement of UPS/DC Battery Room, Equipment Installation for commercial buildings, plants and refinery projects.

Get a quote

Designing Industrial Battery Rooms: Fundamentals and Standards

Industrial battery rooms require careful design to ensure safety, compliance, and operational efficiency. This article covers key design considerations and relevant standards.

Get a quote

6 FAQs about [Equipment room battery cabinet assembly site]

What is a battery cabinet / rack?

EverExceed designs customized battery cabinets / racks for individual batteries. The cabinet or racking system can be specified to accomodate any battery cell. From flooded to sealed, from lead acid to nickel cadmium and from vertical to horizontal all kinds of battery cabinet / rack can be designed flexibly to save the space in battery room.

What are the safety requirements related to batteries & Battery rooms?

Employers must consider exposure to these hazards when developing safe work practices and selecting personal protective equipment (PPE). That is where Article 320, Safety Requirements Related to Batteries and Battery Rooms comes in.

What should be included in a battery room?

Cabinets or racks shall be provided in the battery room for storing maintenance tools and safety equipment. These cabinets and racks shall be acid or alkaline resistant as applicable. Battery rooms shall be vented to the outside air by forced ventilation to prevent accumulation of hydrogen and to maintain design temperature.

Why is a battery room important?

A well-designed battery room ensures safety, compliance, and optimal battery performance while facilitating maintenance and future expansion. free hydrogen venting calculator Designing Industrial Battery Rooms: Fundamentals and Standards Industrial battery rooms require careful design to ensure safety, compliance, and operational efficiency.

What is battery room safety?

Battery room safety involves implementing strict protocols to prevent electrical hazards, chemical exposure, and fire risks. Behind the silent hum of many critical systems—data centers, manufacturing plants, hospitals, and even renewable energy facilities—lie battery rooms powering operations around the clock.

What is a VRLA battery assembly cabinet?

EverExceed VRLA battery assembly cabinets are very durable, and easy to install.Engineered for use with most type of battery terminal models, these cabinets can fit a wide variety of applications. This solution is completely customizable and flexible to support your application requirement.

Guess what you want to know

-

What brands of site energy battery cabinet equipment are there

What brands of site energy battery cabinet equipment are there

-

What are the energy battery cabinet equipment on the site

What are the energy battery cabinet equipment on the site

-

Sri Lanka outdoor communication battery cabinet price outdoor site

Sri Lanka outdoor communication battery cabinet price outdoor site

-

Lithium battery site cabinet base station energy composition

Lithium battery site cabinet base station energy composition

-

Lithium battery site cabinet type

Lithium battery site cabinet type

-

Liquid Battery Site Cabinet

Liquid Battery Site Cabinet

-

Eritrea site energy battery cabinet agent

Eritrea site energy battery cabinet agent

-

Nigeria outdoor battery cabinet equipment BESS

Nigeria outdoor battery cabinet equipment BESS

-

Lithium Battery Site Cabinet Base Station Energy Flow

Lithium Battery Site Cabinet Base Station Energy Flow

-

Congo Brazzaville Energy Storage Battery Cabinet Outdoor Site Price

Congo Brazzaville Energy Storage Battery Cabinet Outdoor Site Price

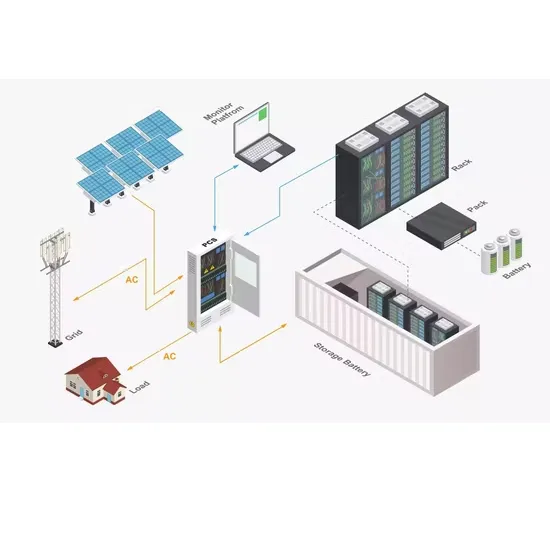

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.