Battery Assembly Equipment – Infinite Industries

Leko is fully owned and operated by The Infinite Industries Group of Companies. For over 20 years, Leko has been designing, installing, and improving lead acid battery assembly line

Get a quote

enveloping/wrapping & stacking

Our 90° lug brushing system, integrated in most of our enveloping machines prevents twisting of the lugs of soft plates and enables better cast-on quality.

Get a quote

Battery Technology Source (BTS)

From plate making and assembly to acid filling, finishing and formation. BTS is your source of innovative, reliable lead acid battery manufacturing solutions.

Get a quote

Assembly line for battery modules and battery packs

For cell/module pack assembly, PIA Automation offers flexible and highly automated systems for the efficient production of battery cells, modules, and battery packs. These systems are

Get a quote

Simple electrode assembly engineering: Toward a multifunctional lead

Our work shows the exciting potential of lead battery technology and demonstrates the importance of battery architecture optimization toward improved energy storage capacity.

Get a quote

What is Lead Acid Battery? Construction, Working,

The battery which uses sponge lead and lead peroxide for the conversion of the chemical energy into electrical power, such type of battery is called a lead acid

Get a quote

automotive battery production equipment

With our complete assembly solutions for car and truck batteries, we have the expertise to fulfil your needs. Our automotive lead-acid battery production equipment includes

Get a quote

Lead Acid Battery

Construction of Lead Acid Battery The various parts of the lead acid battery are shown below. The container and the plates are the main part of the lead acid battery. The container stores

Get a quote

Lead-acid battery assembly line design

The lead-acid battery is the oldest and most widely used rechargeable electrochemical device in automobile, uninterrupted power supply (UPS), and backup systems for telecom and many

Get a quote

LFP48100 lithium

Product Description LFP48100 lithium iron phosphate battery pack for telecommunications is an advanced product developed and developed in response to the current telecommunications

Get a quote

Assembly line solutions from BTS, the leading battery

The assembly line is the heart of the battery manufacturing process. BTS assembly lines are up to the latest 4.0 industry and smart manufacturing

Get a quote

Supply Fully Automatic Car/Motorcycle Battery

Fully Automatic Motorcycle Battery Assembly Line manufacturers is used for Lead acid battery assembly process. The battery assembly line available for

Get a quote

Quality Lithium ion and LiFePo4 Battery pack

We provide services for different industries, such as solar energy storage system (ESS), RV, marine, boat, golf cart, AGV robot, EV Battery, Motorcycle and

Get a quote

Simple electrode assembly engineering: Toward a

To address this challenge, we optimized the configuration of conventional Pb-acid battery to integrate two gas dif- fusion electrodes. The novel device can work as a Pb-air battery using

Get a quote

Intercell welding solutions from BTS, the leading battery machine

Inter-cell welding (ICW) is the process of fusing the lead straps to connect the batteries'' cells. Most lead-acid batteries are welded through the partition (TTP). Getting inter-cell welding right

Get a quote

Car and industrial battery assembly line solutions from

Our semi. and fully auto. car battery assembly lines are designed according to modular design principles and are particularly compact, allowing our

Get a quote

Car and industrial battery assembly line solutions from BTS, the

Our semi. and fully auto. car battery assembly lines are designed according to modular design principles and are particularly compact, allowing our customers to save valuable space on the

Get a quote

Simple electrode assembly engineering: Toward a multifunctional

Our work shows the exciting potential of lead battery technology and demonstrates the importance of battery architecture optimization toward improved energy storage capacity.

Get a quote

Lead batteries for utility energy storage: A review

Lead–acid batteries are supplied by a large, well-established, worldwide supplier base and have the largest market share for rechargeable batteries both in terms of sales value

Get a quote

Fully Automatic Automotive Battery Assembly Line

Our fully automatic automotive battery assembly line consists of multiple stations. General functions include post position check and entry gate control.

Get a quote

Assembly line for battery modules and battery packs

It can be integrated as a stand-alone production line or as a pre-assembly process in the final assembly of the battery module. It ensures reliable electrical connections and is designed for

Get a quote

Innovating battery assembly

Driving the future of electric vehicle battery production The world of electromobility and battery manufacturing is rapidly evolving, and the highly diverse battery manufacturing processes

Get a quote

Guess what you want to know

-

China Unicom Base Station Lead-Acid Battery Assembly

China Unicom Base Station Lead-Acid Battery Assembly

-

Third-party communication base station lead-acid battery equipment

Third-party communication base station lead-acid battery equipment

-

Integrated communication base station battery

Integrated communication base station battery

-

Battery for integrated cabinet of communication base station

Battery for integrated cabinet of communication base station

-

Lithuanian communication base station lead-acid battery equipment manufacturer

Lithuanian communication base station lead-acid battery equipment manufacturer

-

Malawi communication base station lead-acid battery equipment manufacturer

Malawi communication base station lead-acid battery equipment manufacturer

-

Madagascar Telecom Integrated Base Station Battery Station

Madagascar Telecom Integrated Base Station Battery Station

-

Comoros emergency communication base station lead-acid battery

Comoros emergency communication base station lead-acid battery

-

Morocco communication base station lead-acid battery bidding

Morocco communication base station lead-acid battery bidding

-

Base station lead-acid battery charging

Base station lead-acid battery charging

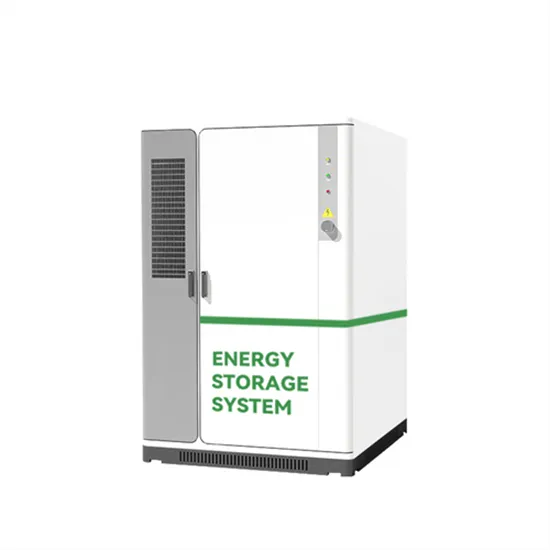

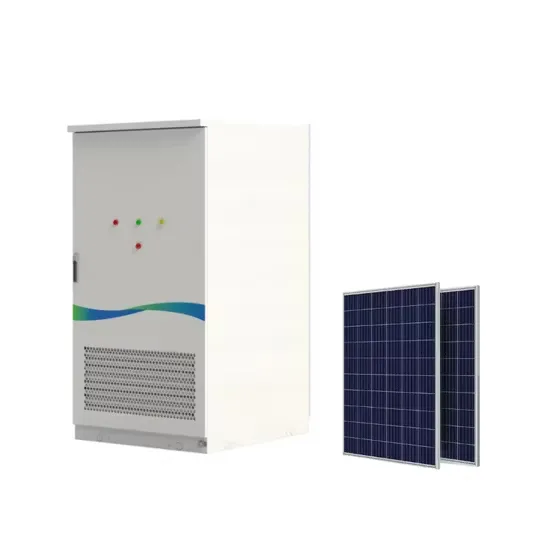

Industrial & Commercial Energy Storage Market Growth

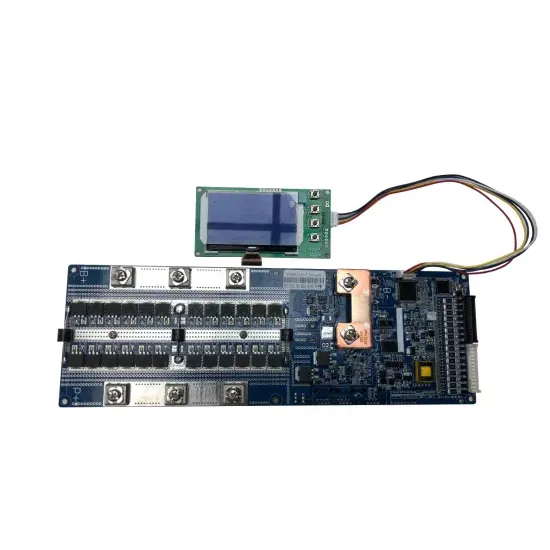

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.