12V to 120V Inverter: How It Works & What You Need

A 12V to 120V inverter can convert DC power (12V) into AC power (120V), making it compatible with household appliances. These inverters are

Get a quote

Can You Power a Fridge Freezer from a 12V Inverter?

A 12V inverter is an electrical device that converts DC (direct current) power, typically from a 12-volt battery or vehicle electrical system, into AC (alternating current) power, which is what

Get a quote

How to Connect a Large or Small Inverter to a Battery

When does a small inverter''s power come from a 12V DC outlet and when does that inverter need to be connected to a battery? The basic decision is based on the maximum

Get a quote

How to Connect a Large or Small Inverter to a Battery

When does a small inverter''s power come from a 12V DC outlet and when does that inverter need to be connected to a battery? The basic

Get a quote

Can I Attach My Small Inverter Directly to the Battery?

Yes, you can attach a small inverter directly to a battery, but doing it safely requires understanding voltage compatibility, wire sizing, and overload risks. Many DIYers assume it''s

Get a quote

Connect an Automatic UPS/Inverter to the Home

How to connect an automatic UPS/inverter to your home supply system. Our step-by-step guide covers wiring, safety tips, and expert advice .

Get a quote

Running an Inverter off a Prius for Backup Power

Minor loads such as a radio and lights can be powered by rechargeable batteries or a small inverter in my truck. However, the inability to

Get a quote

Can I Run A 12V Inverter On A 24V Battery? Solutions And Best

No, a 12V inverter cannot operate on a 24V battery without modification. Connecting a 12V inverter to a 24V battery can cause damage to the inverter. The inverter is

Get a quote

How Big of an Inverter Can My Car Battery Handle?

Typically, a 12-volt car battery can support an inverter with a power range of about 150 watts to 1500 watts. Please note, however, that car batteries are not suitable for driving

Get a quote

Can I Connect a 12V Inverter to a 24V Battery Bank

Connecting a 12V inverter directly to 24V can cause the inverter to overheat, shut down, or suffer permanent damage. Some inverters have built-in protections that might shut

Get a quote

Types of Power Inverters And How To Choose

It can also be used to generate electricity. When the system and battery are unable to carry the power supply, the public grid switches to power the home. In other words, a hybrid

Get a quote

Can you run a 240v appliance on 12v

To operate a 240V appliance on a 12V power source, a voltage conversion mechanism is necessary. One such device commonly used for this purpose is

Get a quote

Charging Battery While Connected To Inverter: The

Power source options How to connect the charging system Following the outlined method below, you can ensure uninterrupted power by charging your battery

Get a quote

How to Safely Connect a Battery to an Inverter: A

Learn how to safely connect your batteries to your inverter with our guide. Avoid common wiring mistakes to optimize performance and extend

Get a quote

How to Safely Connect a Battery to an Inverter: A Step-by-Step

Learn how to safely connect your batteries to your inverter with our guide. Avoid common wiring mistakes to optimize performance and extend system life.

Get a quote

How Big of an Inverter Can My Car Battery Handle?

Typically, a 12-volt car battery can support an inverter with a power range of about 150 watts to 1500 watts. Please note, however, that car

Get a quote

How to Design an Inverter – Theory and Tutorial

In this post I have explained the fundamental tips and theories which may be useful for the newcomers while designing or dealing with basic

Get a quote

Can I give 12V DC to power inverter through PC Power supply?

Assuming you have a good reason for doing this, I''d check that the DC voltage input to the inverter from the PC supply doesn''t exceed inverter input limits, within the range of the

Get a quote

Can I Use a 24V Inverter with a 12V Battery? Compatibility and

A 12V battery cannot supply the necessary voltage to the inverter, leading to excessive current draw. This excessive current can generate heat, potentially causing the

Get a quote

Can I Run A 12V Inverter On A 24V Battery? Solutions And Best

To use a 12V inverter with a 24V battery, a DC-DC buck converter can be employed. This device reduces the 24V input down to 12V for the inverter, ensuring safe and

Get a quote

Can I connect an inverter directly to a battery?

Yes, you can connect an inverter directly to a battery bank. Once the batteries are connected correctly, simply route the positive and negative wires from the inverter to the

Get a quote

Can I Use A 24V Battery Bank With A 12V Inverter? Compatibility

Yes, you can use a 24V battery bank with a 12V inverter, but you need a Switched-Mode Power Supply (SMPS). The SMPS will convert the 12V to the necessary 28V for

Get a quote

6 FAQs about [Can a 12v power supply be connected to a high power inverter ]

Can a 12V battery be used as an inverter?

If you are using a 12V battery, then the input voltage of the inverter must match the battery voltage. If the specifications of the battery and the inverter do not match, the system will not operate stably and may even damage the equipment. In addition, choose the right inverter power and battery capacity for your home or commercial needs.

Can a small power inverter be plugged into a 12 volt outlet?

Some small power inverters are equipped with DC power cords with plugs that can be plugged into a 12 volt vehicle outlet. Some have a cord set that have battery clips identified as Positive (Red color) and Negative (Black color). Some small inverters have two cords supplied; one with a plug and one with battery clips. 12 Volt Outlets

Do inverters have to be connected to a battery?

Above 200 watts of maximum power output an inverter has to be connected to a battery. This avoids fuses blowing in vehicular electric systems and the subsequent hunt for locating and replacing a blown outlet fuse. Most battery clip cables are not equipped with a fuse. Battery clips are only used for brief temporary connections to a 12 volt battery.

How much power does an inverter draw from a battery?

I don't expect to be drawing more than 300-400 W, 240 V from the inverter. Think of it as a home-made UPS for my office. As long as the load does not exceed the charge rrate the battery will remain fully charged and idle while the charger directly powers the inverter watts + efficiency losses. The battery just acts as a capacitor.

Do inverters and batteries need to match?

The inverter and batteries must match in terms of voltage, capacity, and power output. If you are using a 12V battery, then the input voltage of the inverter must match the battery voltage. If the specifications of the battery and the inverter do not match, the system will not operate stably and may even damage the equipment.

What happens if a battery is not connected to the inverter?

A proper connection between the battery and the inverter helps prevent overcharging and overdischarging. Improper connection between the inverter and the battery may result in the inverter failing to accurately read the battery's voltage information, which may cause the battery to be overcharged or over-discharged.

Guess what you want to know

-

Inverter power supply connected to DC

Inverter power supply connected to DC

-

How big of an inverter can a 12v 45AH power supply be

How big of an inverter can a 12v 45AH power supply be

-

Water pump inverter connected to outdoor power supply

Water pump inverter connected to outdoor power supply

-

Does the inverter use a 12V power supply

Does the inverter use a 12V power supply

-

Battery outdoor power supply connected to water pump inverter

Battery outdoor power supply connected to water pump inverter

-

High power lithium battery with inverter

High power lithium battery with inverter

-

How high a temperature can a communication base station inverter withstand when connected to the grid

How high a temperature can a communication base station inverter withstand when connected to the grid

-

Dominic Energy Storage Inverter Power Supply

Dominic Energy Storage Inverter Power Supply

-

High power 2kw inverter production

High power 2kw inverter production

-

Can a mobile outdoor power supply be charged with an inverter

Can a mobile outdoor power supply be charged with an inverter

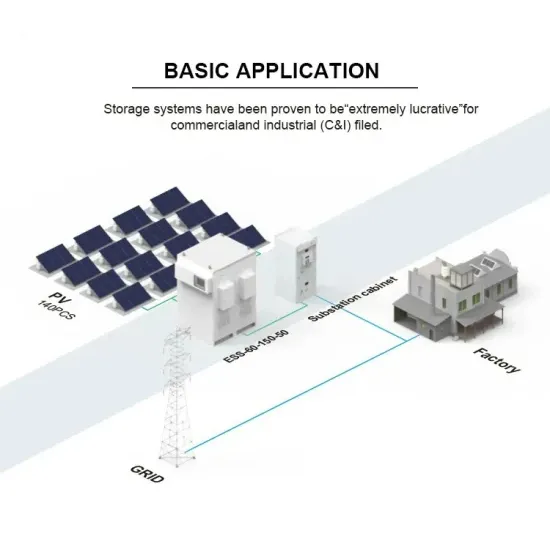

Industrial & Commercial Energy Storage Market Growth

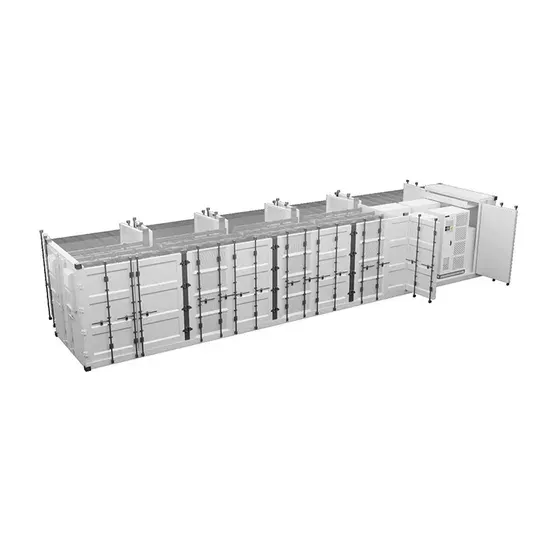

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.