Humidity Control: Solutions for battery systems

To avoid water condensation the absolute humidity inside the system must be kept at a level which will prevent the crossing of the dew point curve at the lowest temperature inside the

Get a quote

Battery Room Ventilation and Safety

It is common knowledge that lead-acid batteries release hydrogen gas that can be potentially explosive. The battery rooms must be adequately ventilated to prohibit the build-up of

Get a quote

GPM Energy Management System (EMS) –

Highlights of the GPM Energy Management System (EMS) The EMS is an energy management platform responsible for controlling power absorption and

Get a quote

Guest Room Energy Management System

Hotel Service Corp. offers a full service guest room Energy Management System (EMS) for hotels and timeshares. This leading-edge solution features the

Get a quote

Utility-scale battery energy storage system (BESS)

Introduction Reference Architecture for utility-scale battery energy storage system (BESS) This documentation provides a Reference Architecture for power distribution and conversion – and

Get a quote

Battery Energy Storage System Cooling Solutions | Kooltronic

A specialized enclosure air conditioner from Kooltronic can help extend the lifespan of battery energy storage systems and improve the efficiency and reliability of associated electronic

Get a quote

ID Number:

The Standard requires that systems designed to control humidity must be able to maintain a dew-point temperature of 16.8°C (62.2°F). There are no established lower humidity limits for

Get a quote

Free cooling and indoor humidity level in telecommunication base

Free cooling is a well-proven method for reducing power consumption in thermal management of telecommunication base stations compared with traditional approach

Get a quote

UPS Room Requirements & Cooling Guide

A UPS requires a stable environment to operate efficiently and prolong battery life. Key considerations include: Ventilation: Ensure adequate airflow to

Get a quote

Intelligent building control systems for thermal comfort and energy

Finally, this paper discusses the challenges faced in the use of AI for energy productivity and comfort improvement, and opens main future directions in relation with AI

Get a quote

Battery Energy Storage System Cooling Solutions

A leading manufacturer of battery energy storage systems contacted Kooltronic for a thermal management solution to fit its rechargeable power system.

Get a quote

Ventilation and Thermal Management of Stationary Battery

Introduction of developing a joint standard on battery room ventilation. For ASHRAE the goal was to reduce the energy consumption that results from traditional battery room ventilation systems

Get a quote

Energy Management Information Systems Technical

Acknowledgments This document summarizes and contributes to a considerable body of work at the Federal Energy Management Program and U.S. Department of Energy''s Building

Get a quote

Department of the Army FLW Regulation 420-3

Summary. This regulation will define and direct energy-related conservation measures with an intent to further alter and shape the current culture of the installation''s population, curb utility

Get a quote

Battery Energy Storage System Cooling Solutions

A specialized enclosure air conditioner from Kooltronic can help extend the lifespan of battery energy storage systems and improve the efficiency and

Get a quote

Building Energy Management System

One way to increase the energy efficiency of buildings is to implement a building energy management system (BEMS). BEMSs are centralised, computer-based systems, which

Get a quote

Make Humidification Adjustments

Until very recently, most data center managers tightly controlled humidity, keeping it between 45 and 50% relative humidity (RH). The concern was that low humidity could lead to electrostatic

Get a quote

Micro-environment strategy for efficient cooling in

A micro-environment strategy has been developed to address mess airflow, hot spots, and excessive energy consumption issues in telecommunication base stations .

Get a quote

Free cooling and indoor humidity level in telecommunication base stations

Free cooling is a well-proven method for reducing power consumption in thermal management of telecommunication base stations compared with traditional approach

Get a quote

Beyond Temperature: The Importance of HVAC Humidity Control

A: HVAC systems balance temperature and humidity for better energy use and comfort. They use demand-controlled ventilation to adjust both based on current conditions

Get a quote

Microsoft Word

Second, the equipment used within a P25 base station now includes commercial–grade switches, routers, firewalls, trunking repeaters, Rx multi-couplers, and Tx combiners. Much of the P25

Get a quote

Smart Building Sensors: a Comprehensive Guide to Facility

The Milesight smart lighting control system was implemented in a Dubai commercial building to enhance energy efficiency and lighting management. By using IoT-based technology, the

Get a quote

Battery Room Ventilation and Safety

BATTERY ROOM VENTILATION AND SAFETY It is common knowledge that lead-acid batteries release hydrogen gas that can be potentially explosive. The battery rooms must be adequately

Get a quote

Cooling for Mobile Base Stations and Cell Towers

Another requirement for a cooling system in base stations and cell towers is humidity control. Dry air will make static to burn the communication equipment, thus humidity control is as important

Get a quote

Energy Recovery for Battery Room Ventilation | Greenheck Blog

This technology has numerous advantages in a battery room environment. It continually exhausts the hydrogen gas to prevent buildup in the room, keeping the hydrogen

Get a quote

6 FAQs about [Humidity requirements for base station room energy management system]

Does Standard 55 require a minimum humidity level?

The Standard requires that systems designed to control humidity must be able to maintain a dew-point temperature of 16.8°C (62.2°F). There are no established lower humidity limits for thermal comfort; consequently, Standard 55 does not specify a minimum humidity level.

What is the recommended humidity level for occupied spaces?

ASHRAE Standard 62.1-2016, "Ventilation for Acceptable Indoor Air Quality", plus ASHRAE BOD approved addenda.requires that relative humidity levels be designed to be limited to 65% or less for mechanical systems with dehumidification capability.

What are the requirements for a stationary battery ventilation system?

Ventilation systems for stationary batteries must address human health and safety, fire safety, equipment reliability and safety, as well as human comfort. The ventilation system must prevent the accumulation of hydrogen pockets greater than 1% concentration.

Does Standard 62.1 have humidity limitations?

For other mechanical system types or where spaces are not served by mechanical systems, Standard 62.1 has no humidity limitations.

How should a battery room be designed?

Battery rooms shall be designed with an adequate exhaust system which provides for continuous ventilation of the battery room to prohibit the build-up of potentially explosive hydrogen gas. During normal operations, off gassing of the batteries is relatively small.

What is the minimum illumination level in a battery room?

Illuminance levels in the battery room shall be designed to meet IESNA Lighting Handbook recommendations with a minimum illumination level of 300 lux (30 fc). The lighting design shall consider the type of battery rack and the physical battery configuration to ensure that all points of connection, maintenance and testing are adequately illuminated.

Guess what you want to know

-

North Macedonia Base Station Room Energy Management System

North Macedonia Base Station Room Energy Management System

-

Middle East Base Station Energy Management System Signal Tower

Middle East Base Station Energy Management System Signal Tower

-

What kind of project is the base station energy management system

What kind of project is the base station energy management system

-

Base Station Energy Management System On-site Safety Inspection

Base Station Energy Management System On-site Safety Inspection

-

What is the load of the base station energy management system in kw

What is the load of the base station energy management system in kw

-

Kiribati base station computer room energy storage 7MWh

Kiribati base station computer room energy storage 7MWh

-

Communication base station energy storage system room and optical exchange

Communication base station energy storage system room and optical exchange

-

Requirements for establishing a communication base station energy storage system

Requirements for establishing a communication base station energy storage system

-

How much does a base station energy management system cost

How much does a base station energy management system cost

-

Cuba base station computer room hybrid energy room

Cuba base station computer room hybrid energy room

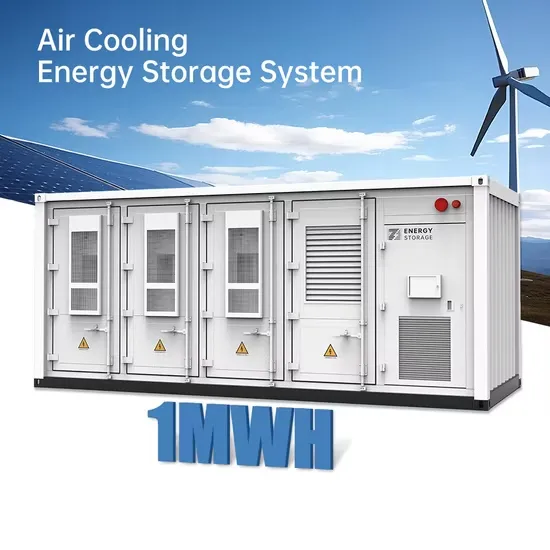

Industrial & Commercial Energy Storage Market Growth

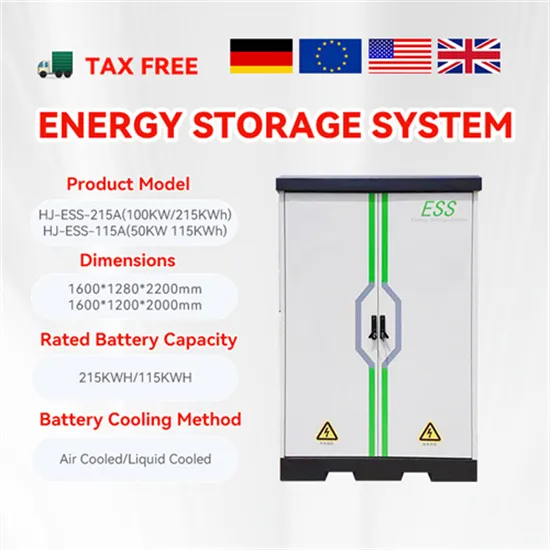

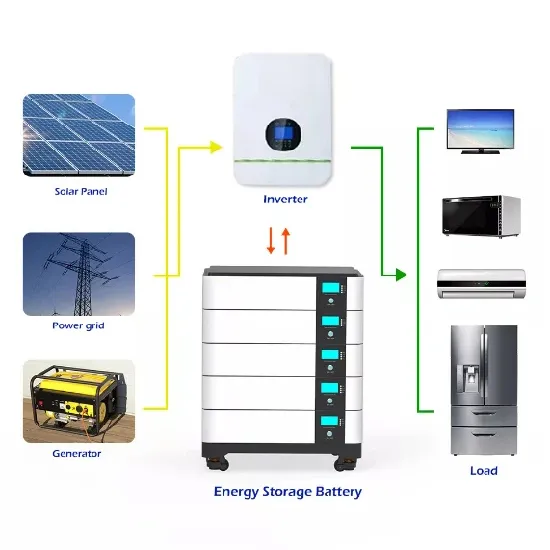

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.