SHOCK AND VIBRATION RESPONSE SPECTRA COURSE

The sine sweep test may begin at a low frequency and then sweep to a high frequency, or vice-versa. Some specifications require several cycles, where one cycle is defined as from low to

Get a quote

Step-by-Step Guide to Vibration Testing of Lithium

Configure the vibration parameters (frequency, amplitude, and sweep rate) based on the chosen standard. Ensure the testing environment

Get a quote

No. 4 Measurement of frequency response function

In this column, I will talk about the measurement of frequency response function using sweep signals, etc. To measure the natural vibration frequency, there is

Get a quote

Battery Pack Vibration Testing Methods

Sinusoidal testing uses controlled single-frequency sweeps (typically 5-500Hz) to identify resonant frequencies, while random vibration testing applies simultaneous multi

Get a quote

Vibration Test: Ensuring the Reliability of Battery Packs

Vibration test profiles for lithium-ion batteries typically include sine sweep and random vibration tests. These profiles help simulate real-world conditions to

Get a quote

Helpful Guidelines for Single-Axis Shaker Testing

Roman Vinokur, Westlake Village, California This article presents common-sense guidelines for single-axis sweep sine and random vibration testing. Several actual case histories are

Get a quote

Vibration Sweep Test for Battery Structure

I am trying to simulate the effects of vibration sweep test on a battery structure, with the acceleration profiles ( converted to loads) as input,

Get a quote

Battery vibration test – an important part of battery quality assurance

At present, the products of mainstream OEMs and battery pack manufacturers need to undergo battery vibration test. The magnitude of the vibration that the battery pack bears is

Get a quote

Lithium ion Power Battery Cycling and Vibration Test

It can be seen that after the charging and discharging cycle, the internal resistance of the battery will slightly decrease. This is because the

Get a quote

Cell geometry influences on the vibration performance of lithium

This study uses the International Electrotechnical Commission standard (IEC62660–2) to investigate the performance of pouch, cylindrical, and prismatic lithium-ion

Get a quote

Battery Mechanical Abuse – The big vibration test for EVs

Here is a list of some of the standards for vibration testing. Random vibration, shock, and sinusoidal or sine sweep tests are the most common vibration tests for batteries.

Get a quote

Analysis and Optimization of Fatigue Caused by Vibrations in the

The quick-replacement battery box structure was then optimized according to the analysis results and lightweight targets. The results of sweep frequency and random vibration analyses

Get a quote

Sine Sweep Test

A frequency sweep allows the engineer to quickly observe a product''s response in the frequency range of the operational environment. During a sine sweep test, a vibration

Get a quote

Sweep Rate Calculator

The Sweep Rate (ν) is the speed at which a controller increases or decreases frequency in sine vibration testing. Cathodic Current (Ic) is a flow of charged particles, such as electrons or ions,

Get a quote

The Ultimate Guide to Vibration Testing for EV Battery Packs

Sweep-frequency vibration involves changing the frequency according to a specific rule, and it can be categorized into linear sweep and logarithmic sweep based on the sweep

Get a quote

Lithium ion Power Battery Cycling and Vibration Test

It can be seen that after the charging and discharging cycle, the internal resistance of the battery will slightly decrease. This is because the vibration not only causes the

Get a quote

Vibration Test 101: A Full Guide

In addition to identifying natural frequencies, swept sinusoidal vibrations can be used to evaluate the durability of a test specimen over successive frequency

Get a quote

Battery vibration test – an important part of battery

At present, the products of mainstream OEMs and battery pack manufacturers need to undergo battery vibration test. The magnitude of the

Get a quote

Vibration Test: Ensuring the Reliability of Battery Packs

Vibration test profiles for lithium-ion batteries typically include sine sweep and random vibration tests. These profiles help simulate real-world conditions to ensure the battery''s durability and

Get a quote

battery vibration test, bump test, humidity test comply to UN38.3

The vibration should be in a sinusoidal waveform with a frequency swing between 7 and 200 Hz and back to a logarithmic sweep of 7 Hz for 15 minutes. This vibration process must be

Get a quote

Sweep Rate Calculator | Calculate Sweep Rate

Sweep Rate calculator uses Sweep Rate = (Cathodic Current/ (2.69* (10^8)*Number of electrons given CI*Concentration given CI* (Diffusion Constant^0.5)*Area of Electrode))^ (4/3) to

Get a quote

Vibration Sweep Test for Battery Structure

I am trying to simulate the effects of vibration sweep test on a battery structure, with the acceleration profiles ( converted to loads) as input, using Harmonic Analysis method.

Get a quote

Step-by-Step Guide to Vibration Testing of Lithium Batteries

Configure the vibration parameters (frequency, amplitude, and sweep rate) based on the chosen standard. Ensure the testing environment matches real-world conditions,

Get a quote

Shaker Vibration Testing

Sine Vibration Testing A Sine vibration test will only excite one frequency at a given time. The voltage drive used to excite the shaker system will be shaped

Get a quote

Variable-sweep-rate testing: a technique to improve the

SUMMARY A technique has been established to improve the quality and reduce the acquisition time of frequency response and vibration data. The technique involves sweeping at a variable

Get a quote

Mastering Vibration Testing: Unveiling 26 Essential

Explore the essential insights of vibration testing, Uncover the fundamentals, standards, and applications of vibration testing to elevate

Get a quote

6 FAQs about [What is the sweep frequency vibration of the battery cabinet]

What is the difference between fixed frequency vibration and sweep frequency vibration?

Fixed-frequency vibration is mainly used to test the resistance to resonance frequency vibration and predetermined frequency vibration. Sweep-frequency vibration involves changing the frequency according to a specific rule, and it can be categorized into linear sweep and logarithmic sweep based on the sweep speed.

What are the different types of vibration tests for batteries?

Here is a list of some of the standards for vibration testing Random vibration, shock, and sinusoidal or sine sweep tests are the most common vibration tests for batteries. The main differences between the standards are the type of excitation, the vibration profiles, and the frequency range.

What is sweep frequency vibration?

Sweep-frequency vibration involves changing the frequency according to a specific rule, and it can be categorized into linear sweep and logarithmic sweep based on the sweep speed. The frequency change in linear sweep is linear, meaning it covers a certain number of hertz per unit time, expressed in Hz/s or Hz/min.

What are vibration test profiles for lithium-ion batteries?

Vibration test profiles for lithium-ion batteries typically include sine sweep and random vibration tests. These profiles help simulate real-world conditions to ensure the battery’s durability and reliability.

How long does it take to vibrate a battery?

The vibration should be in a sinusoidal waveform with a frequency swing between 7 and 200 Hz and back to a logarithmic sweep of 7 Hz for 15 minutes. This vibration process must be repeated 12 times for each of the three mutually perpendicular battery mounting orientations for a total of 3 hours.

What are the standards for vibration testing of battery systems?

Most testing standards for battery systems include vibration tests. The national mandatory standard GB38031 ⇱, issued in 2020, clearly defines the methods and requirements for vibration testing of power battery systems. The relevant standards for vibration testing of battery systems in both domestic and international contexts are as follows:

Guess what you want to know

-

What is a 0 to 10v dimming outdoor battery cabinet

What is a 0 to 10v dimming outdoor battery cabinet

-

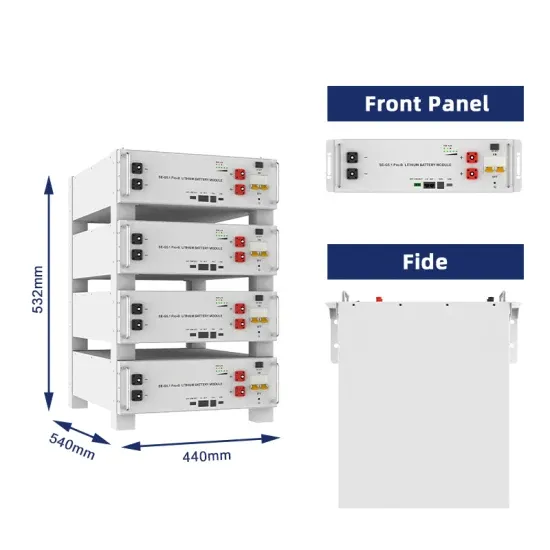

What are the components of the new energy battery cabinet

What are the components of the new energy battery cabinet

-

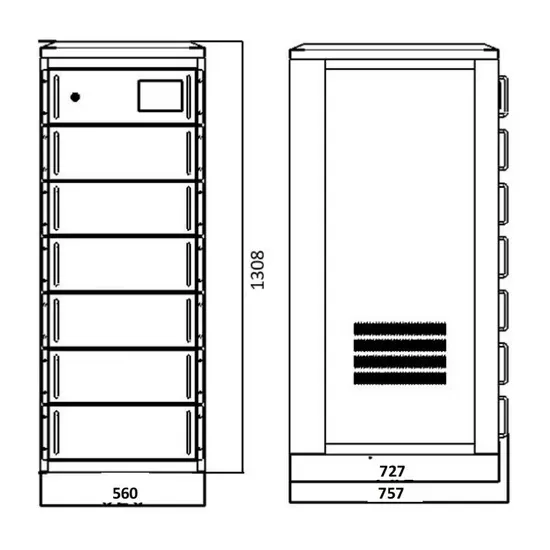

What are the specifications of the new energy battery cabinet

What are the specifications of the new energy battery cabinet

-

What is the internal connection technology of the battery cabinet

What is the internal connection technology of the battery cabinet

-

What does a lithium titanate energy storage battery cabinet include

What does a lithium titanate energy storage battery cabinet include

-

What are the new energy battery cabinet brands

What are the new energy battery cabinet brands

-

What is the normal current of a 9v battery in an energy storage cabinet

What is the normal current of a 9v battery in an energy storage cabinet

-

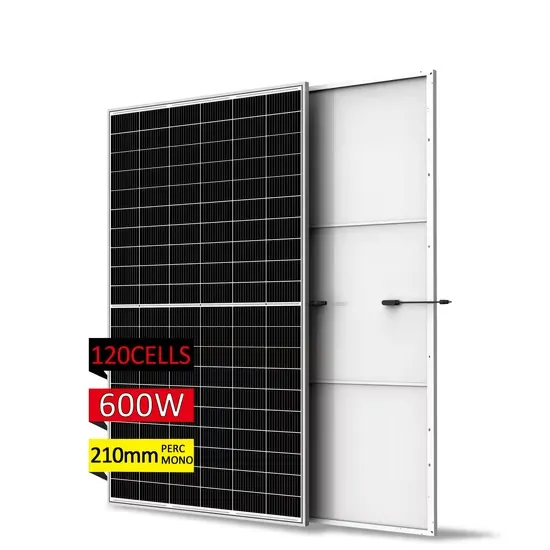

What kind of battery is best for a power frequency inverter

What kind of battery is best for a power frequency inverter

-

What is the price of Malta outdoor communication battery cabinet

What is the price of Malta outdoor communication battery cabinet

-

What are the battery cabinet layout requirements

What are the battery cabinet layout requirements

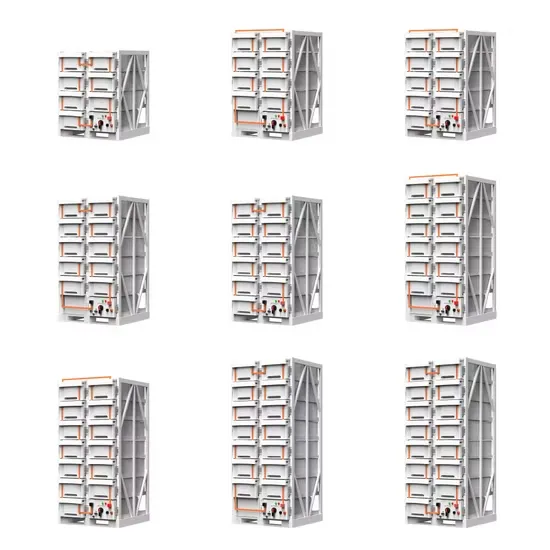

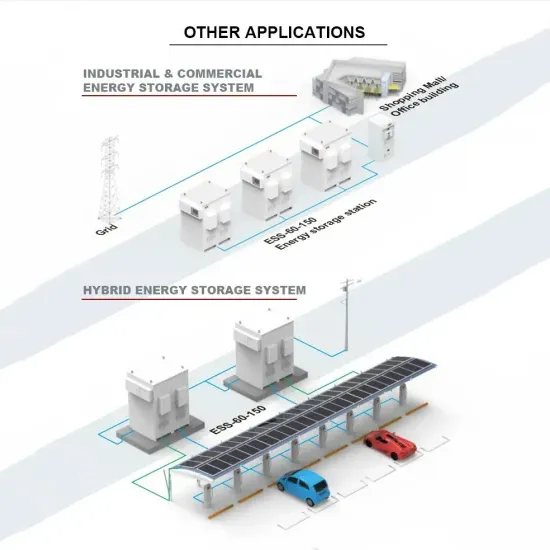

Industrial & Commercial Energy Storage Market Growth

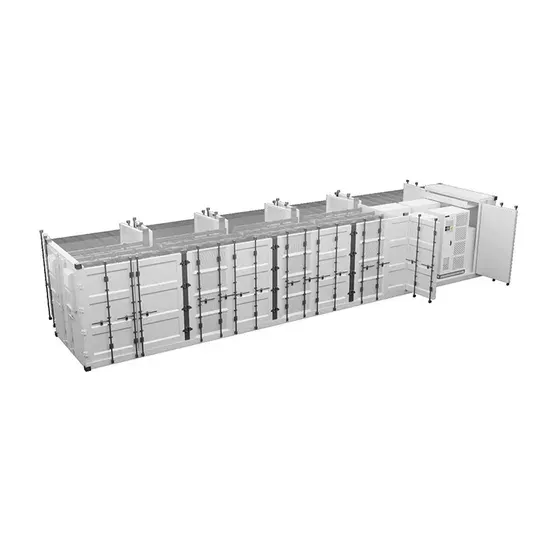

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.