How Are Lithium Battery Packs Assembled?

By following the key steps involved in lithium battery pack assembly, including cell selection and testing, cell arrangement and connection, BMS integration, and final assembly and testing,

Get a quote

Battery Storage Era: 5 Reasons BESS Is

Here we look at the top 5 markers which highlight the rise of the battery energy storage solutions market as the most popular and the fastest

Get a quote

Battery Pack Assembly: From Cells to Power Packs

The journey of a battery''s transformation from a collection of individual cells to a powerful energy source involves several intricate steps. In this article, we focus on the final piece of this

Get a quote

Tracking the EV battery factory construction boom

Battery factories are popping up across North America. Here''s where they are and how the Inflation Reduction Act influenced the boom.

Get a quote

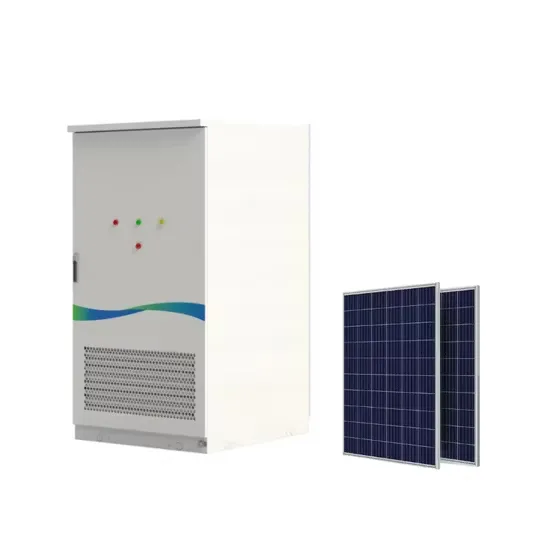

5-In-One Energy Storage System & Home ESS Solutions

Integrating Solar Inverter, EV DC Charger, Battery PCS, Battery Pack, and EMS into one powerful energy system - this is our revolutionary 5-in-One Home ESS. Simplified to give you a smart

Get a quote

How Lithium-ion Batteries Work | Department of Energy

Lithium-ion batteries power the lives of millions of people each day. From laptops and cell phones to hybrids and electric cars, this technology

Get a quote

Powerwall – Home Battery Storage | Tesla

Powerwall is a home battery that provides whole-home backup and protection during an outage. See how to store solar energy and sell to the grid to earn credit.

Get a quote

DOE ESHB Chapter 3: Lithium-Ion Batteries

Abstract Lithium-ion batteries are the dominant electrochemical grid energy storage technology because of their extensive development history in consumer products and electric vehicles.

Get a quote

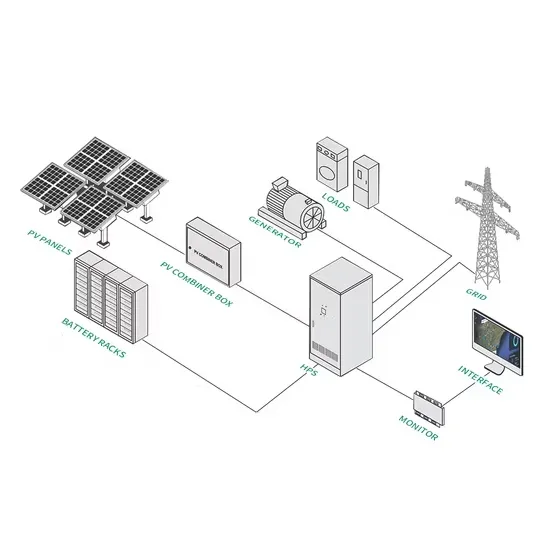

The basic components of a battery energy storage

The basic components of a battery energy storage system This is part one of our new series which introduces the basics of battery energy storage systems

Get a quote

Mastering the Battery Pack Assembly Process: A Comprehensive

The battery pack assembly process is a meticulously planned sequence of steps that transforms individual components into a fully functional battery pack. It begins with the

Get a quote

Battery Pack Assembly: Techniques and Materials Used

Electric vehicles rely on lithium-ion batteries for energy storage, making the battery pack the heart of an EV. Its assembly involves intricate processes to ensure reliability, energy

Get a quote

Key Points of Lithium Battery PACK Manufacturing

Dive into the detailed process behind these essential energy storage solutions! From selecting and matching battery cells to assembling,

Get a quote

Designing a Lithium-Ion Battery Pack: A Comprehensive Guide

Among various energy storage technologies, lithium-ion battery packs have emerged as the preferred choice due to their high energy density, long cycle life, and

Get a quote

Battery Module: Manufacturing, Assembly and Test Process Flow.

In this article, we will look at the Module Production part. The Remaining two parts Pack Production and Vehicle Integration will follow in the next articles. 1. Module Production.

Get a quote

Battery Module: Manufacturing, Assembly and Test

In this article, we will look at the Module Production part. The Remaining two parts Pack Production and Vehicle Integration will follow in the

Get a quote

Lithium Battery Cell, Module, EV Battery System Manufacturer

LITHIUM STORAGE is a lithium technology provider. LITHIUM STORAGE focuses on to deliver lithium ion battery, lithium ion battery module and lithium based battery system with BMS and

Get a quote

Lithium-ion Battery Module and Pack Production Line Process Flow

On the Pack assembly line, the battery modules are assembled into a complete pack, which includes the module casing, the heat dissipation system, the Battery Management

Get a quote

Battery Pack Assembly: Techniques and Materials Used

Electric vehicles rely on lithium-ion batteries for energy storage, making the battery pack the heart of an EV. Its assembly involves intricate

Get a quote

Lithium-ion Battery Module and Pack Production Line

On the Pack assembly line, the battery modules are assembled into a complete pack, which includes the module casing, the heat dissipation

Get a quote

How to Assemble a Lithium Battery Pack: Step-by-Step Guide for

In this guide, we''ll walk you through everything you need to know – from the basics of what a battery pack is, to the tools and materials required, the step-by-step assembly

Get a quote

China''s Gotion rolls first battery pack off its new US

China''s EV battery developer Gotion High-Tech continues its global expansion, celebrating its latest milestone in new technologies this

Get a quote

How are Lithium-ion Battery Packs Manufactured?

These compact powerhouses drive our modern world, from portable gadgets to renewable energy storage. But how exactly are they made? Lithium-ion battery packs are manufactured through

Get a quote

Mastering the Battery Pack Assembly Process: A

The battery pack assembly process is a meticulously planned sequence of steps that transforms individual components into a fully functional

Get a quote

Key Points of Lithium Battery PACK Manufacturing Process

Dive into the detailed process behind these essential energy storage solutions! From selecting and matching battery cells to assembling, testing, and packaging, discover the

Get a quote

Manual Assembly of Energy Storage Battery Packs: A Step-by

Ever tried solving a 3D puzzle without the picture guide? That''s what manual assembly of energy storage battery packs feels like – equal parts thrilling and nerve-wracking.

Get a quote

6 FAQs about [Energy storage battery pack is being assembled]

What is a battery pack assembly process?

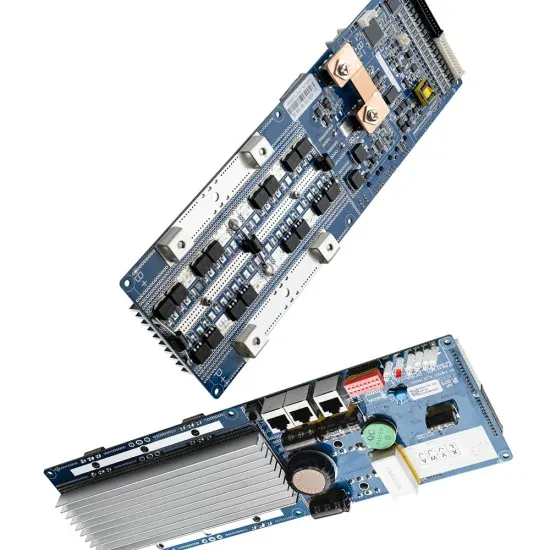

The battery pack assembly process is a meticulously planned sequence of steps that transforms individual components into a fully functional battery pack. It begins with the procurement of high-quality materials, including battery cells, BMS, wiring, and protective casings.

What is the battery pack manufacturing process?

The battery pack manufacturing process involves cell selection, module assembly, wiring, thermal management, and safety integration. Each step ensures efficiency, reliability, and durability. Understanding this process helps manufacturers optimize production, clients get tailored solutions, and consumers receive safer, longer-lasting batteries.

What are the three parts of battery pack manufacturing process?

Battery Module: Manufacturing, Assembly and Test Process Flow. In the Previous article, we saw the first three parts of the Battery Pack Manufacturing process: Electrode Manufacturing, Cell Assembly, Cell Finishing. Article Link In this article, we will look at the Module Production part.

Why is battery pack assembly important?

The significance of the battery pack assembly process lies in its direct impact on the performance and safety of the final product. A well-assembled battery pack ensures optimal energy storage, efficient power delivery, and long-term durability.

What is battery module assembly process?

The battery module assembly process is a crucial step in the battery pack manufacturing process, where individual battery cells are grouped into modules. This stage enhances efficiency, safety, and performance by integrating electrical connections, thermal management systems, and safety features.

What is a battery pack?

Battery packs will increasingly incorporate features tailored for ultra-fast charging and wireless charging technologies, driving innovation in both EVs and EV charging networks. Battery pack assembly is at the heart of the EV revolution, shaping the performance, safety, and sustainability of electric vehicles.

Guess what you want to know

-

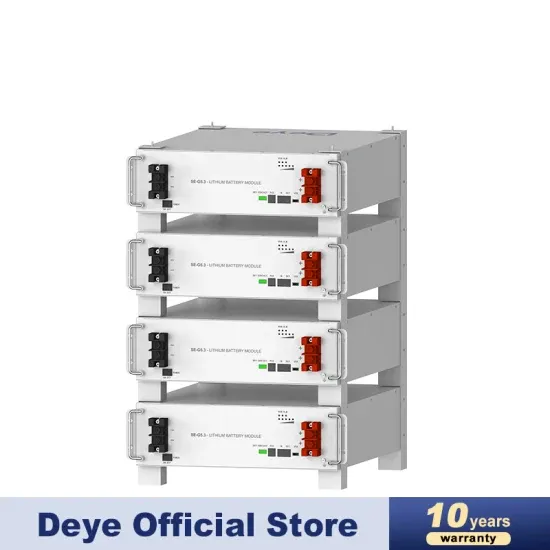

Columbia outdoor energy storage battery pack

Columbia outdoor energy storage battery pack

-

Thailand household energy storage battery pack

Thailand household energy storage battery pack

-

Moldova energy storage pack battery

Moldova energy storage pack battery

-

Off-grid energy storage battery pack

Off-grid energy storage battery pack

-

40 kWh energy storage battery system lithium battery pack

40 kWh energy storage battery system lithium battery pack

-

Energy storage cabinet lithium battery pack 12v

Energy storage cabinet lithium battery pack 12v

-

Energy storage battery pack voltage range

Energy storage battery pack voltage range

-

Energy storage battery pack assembly

Energy storage battery pack assembly

-

Tajikistan rechargeable energy storage battery pack

Tajikistan rechargeable energy storage battery pack

-

Square energy storage pack battery

Square energy storage pack battery

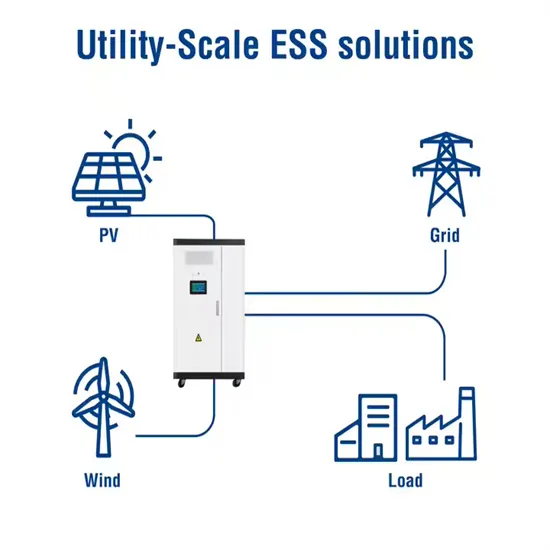

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.