Research on control strategy of permanent magnet direct drive Wind

Download Citation | On Sep 25, 2022, Junrui Wang and others published Research on control strategy of permanent magnet direct drive Wind Power Generation System | Find, read and

Get a quote

Frequency regulation strategy of direct drive

Figure 1 shows the basic structure and control principle of the direct-drive permanent magnet synchronous wind power generation system,

Get a quote

Design Optimization of a Direct-Drive Wind Generator with a

Abstract—This paper presents a large-scale multi-objective design optimization for a direct-drive wind turbine generator concept that is based upon an experimentally validated compu-tational

Get a quote

Direct Drive Permanent Magnet Synchronous Generator:

system integration of the designed generator, connected to the grid through power electronic converters, are simulated using the Matlab/Simulink software suite. The resulting findings

Get a quote

Review of Generator Systems for Direct-Drive Wind Turbines

In order to identify suitable generator concepts for direct-drive wind turbines, the comparisons of different generator systems in literature are discussed with the criteria based on the energy

Get a quote

Design of 20 MW direct‐drive permanent magnet synchronous

In this paper, we explore the design of 20 MW DD-PMSGs for wind turbine systems through a recent CMaO approach. Initially, we introduce an optimal design process utilizing the CNSGA

Get a quote

Full-Converter Wind Turbine Technology

Generator converts mechanical power to AC electric power. Generator can be asynchronous, permanent magnet or synchronous for geared system, pm or synchronous for DD.

Get a quote

Generator design for direct-drive turbines | Wind Turbine System

The following chapter about direct-drive generator systems for wind turbine applications deals with the main aspects which determine the design of such generators,

Get a quote

Modern electric machines and drives for wind power

Abstract With ever-increasing concerns on energy crisis and environmental protection, there is a fast-growing interest in wind power

Get a quote

Frequency regulation strategy of direct drive permanent magnet

Figure 1 shows the basic structure and control principle of the direct-drive permanent magnet synchronous wind power generation system, which is connected to the grid

Get a quote

Control strategies of grid interfaced wind energy conversion system

The main objective of grid side controller is to control the power delivered to the grid, grid synchronization, to supply high quality power to grid and to meet grid code compliance. In

Get a quote

Switching‐angle‐based hybrid modulation method of full wind

A switching-angle-based hybrid modulation method of full wind speed and low carrier wave ratio for direct-drive permanent-magnet wind power generation system is proposed here, which

Get a quote

How do direct-drive wind turbines work?

Direct-drive wind turbines provide a reliable, efficient, and low-maintenance solution for harnessing wind energy. By eliminating the gearbox and using permanent magnet

Get a quote

Power electronics in wind generation systems

This Review discusses the current capabilities and challenges facing different power electronic technologies in wind generation systems from single turbines to the system

Get a quote

Design of 20 MW direct‐drive permanent magnet

In this paper, we explore the design of 20 MW DD-PMSGs for wind turbine systems through a recent CMaO approach. Initially, we introduce an optimal

Get a quote

Electrical generators for direct drive systems: a

This chapter will guide the reader through the various direct drive generator topologies for wind turbines that have been suggested in the literature and outline the ones

Get a quote

The Future of Wind Turbines: Comparing Direct Drive

To eliminate gearbox failure and transmission losses, manufacturers have developed wind turbines without gearboxes. This type of wind turbine

Get a quote

Electrical generators for direct drive systems: a

In a direct drive system the gearbox is removed from the drive train and the generator is directly coupled to the hub of the wind turbine (Fig. 1.1). They both rotate at the

Get a quote

Direct Drive Wind Turbines

Traditional wind turbines use gearboxes to step up the rotational speed (about 100x) from the rotor to the generator, which makes electrical power. This article discusses direct drive wind

Get a quote

Introduction of the Direct Drive Wind Power Generation System

The wind power generation system connected to the grid plays the role of the changing wind energy into mechanical energy by wind turbines, and then converts mechanical energy into

Get a quote

Direct Drive Wind Turbine vs. Geared Drive Wind Turbine

According to the drivetrain condition in a wind generator system, wind turbines can be classified as either direct drive or geared drive groups. To increase the generator rotor rotating speed to

Get a quote

The Future of Wind Turbines: Comparing Direct Drive and Gearbox

To eliminate gearbox failure and transmission losses, manufacturers have developed wind turbines without gearboxes. This type of wind turbine was introduced in 1991,

Get a quote

Cooling techniques in direct-drive generators for wind power

Abstract: Direct-drive generators are an attractive candidate for wind power application since they do not need a gearbox, thus increasing operational reliability and reducing power losses.

Get a quote

Control of variable pitch and variable speed

The grid-side converter needs to work as a voltage source to help regulate the terminal (grid) voltage amplitude and frequency by adjusting the

Get a quote

What Is a Direct-Drive Wind Turbine?

Among the various types of wind turbines, direct-drive wind turbines have emerged as a cutting-edge technology that offers numerous advantages over traditional designs. But what exactly is

Get a quote

Guess what you want to know

-

Mongolia communication base station wind power and photovoltaic power generation energy saving

Mongolia communication base station wind power and photovoltaic power generation energy saving

-

Base station energy wind power generation system

Base station energy wind power generation system

-

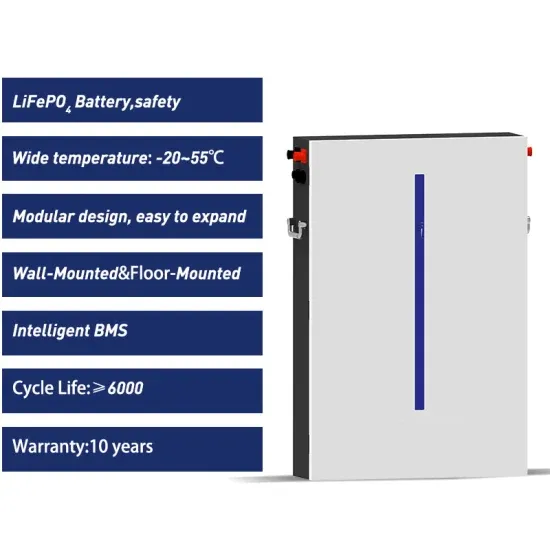

Wind power generation home energy storage battery

Wind power generation home energy storage battery

-

Ireland communication base station wind power and photovoltaic power generation installation

Ireland communication base station wind power and photovoltaic power generation installation

-

Solar power generation can drive water pump inverter

Solar power generation can drive water pump inverter

-

Overall operation of wind power generation system

Overall operation of wind power generation system

-

Off-grid wind power generation energy storage system

Off-grid wind power generation energy storage system

-

Ranking of Portugal s communication base station wind and solar hybrid power generation

Ranking of Portugal s communication base station wind and solar hybrid power generation

-

Different types of wind power generation systems

Different types of wind power generation systems

-

Wind power generation integrated protection system

Wind power generation integrated protection system

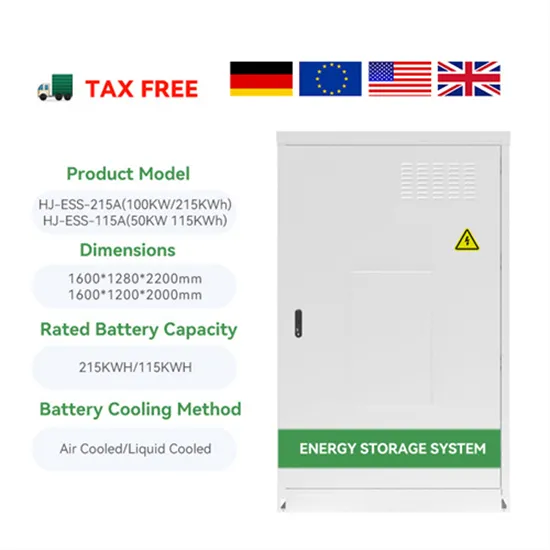

Industrial & Commercial Energy Storage Market Growth

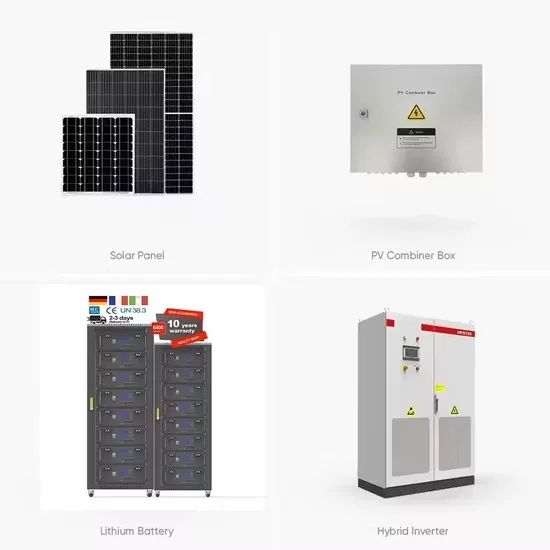

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.