Single Phase vs Split Phase Inverter: Key Differences

Explore the key differences between single phase and split phase inverters in this comprehensive guide. Whether you''re powering basic

Get a quote

What Is A 3 Phase Solar Inverter?

Not necessarily. 3 phase inverters are designed to operate with a balanced 3 phase power output. In this scenario, a neutral conductor isn''t essential for the inverter''s function.

Get a quote

0.75kw Frequency Inverter, Single Phase 120V Input,

1hp (0.75kw) frequency inverter, single phase 120v input, 1 phase and 3 phase 220v output. Come with a V/F control mode, the variable frequency drive

Get a quote

Need three phase 440 from single phase 220

Another option would be to use a 230V rotary phase converter and then step up from there with a 3 phase 460:230 VAC transformer wired backwards. One advantage of this

Get a quote

How to wire three phases for 220V?

I found this manual for a slightly different controller, and it requires a "single-phase 220V power source" for the control panel. The wiring diagram

Get a quote

Three Phase Inverter

Three-Phase output: Provides three separate AC outputs, each 120 degrees out of phase with the others, creating a balanced three-phase power supply. Efficient power conversion: High

Get a quote

Three Phase Inverter | DC-TO-AC INVERTER

Here a critical load requiring 3-phase ac supply of fixed magnitude and frequency has been considered. In case ac mains supply fails, the 3-phase load may be

Get a quote

Key differences between three-phase 220V and three-phase 380V inverters

In this paper, we will discuss the nine core differences between three-phase 220V and three-phase 380V inverters, to help readers more fully understand the application

Get a quote

MOLLOM VFD 3KW 4HP 13A 220V Single or Three

Amazon : MOLLOM VFD 3KW 4HP 13A 220V Single or Three Phase Input to 3 Phase 0-3000 Hz Output Variable Frequency Drive Control Inverter for

Get a quote

HowTo: 240V Supply to a 400V AC Motor

An Inverter Drive is not only able to convert a 230V single phase supply to 230V 3 phase but it also controls both the output Frequency and Voltage to maintain

Get a quote

The difference between inverter output three-phase 220v and three-phase

Under the same current conditions, the power output of three-phase 380V is much greater than that of three-phase 220V. Therefore, in situations where high power output is

Get a quote

How about 220v to 380v three phase inverter

The 220V to 380V three phase inverter uses DC-AC mode and SPWM modulation control technology to convert 220V direct current into 380V alternating current three phase

Get a quote

Single Phase 220V to 3-Phase 380V VFD | ATO

30 hp VFD for sales, converts 1-phase 220V input to 3-phase 380V output, 45A rated current, 50Hz/ 60Hz input frequency, 0-400Hz output frequency. It can

Get a quote

Key differences between three-phase 220V and three

In this paper, we will discuss the nine core differences between three-phase 220V and three-phase 380V inverters, to help readers more fully

Get a quote

Difference Between 220V & 380V 3-Phase Power Supplies

It is clarified that 220V is typically the phase-to-neutral voltage, while 380V is the phase-to-phase voltage in a three-phase system. Inverters can be designed for single-phase

Get a quote

How to wire three phases for 220V?

I found this manual for a slightly different controller, and it requires a "single-phase 220V power source" for the control panel. The wiring diagram connects this to L1 and L2 of the

Get a quote

Single Phase to Three Phase Variable Frequency Drive

Output frequency: 0 to 400 Hz Dimension: 339*231*234 mm Weight: 11 kg When the power grid is single phase 220v/230v/240v, VFD converts it into a DC voltage through a single phase

Get a quote

Can this 400V motor be run on 220V/3 phase?

I''d if possible appreciate some help with figuring whether or not the OEM motor marked 3kW 400V delta 3 phase motor fitted can be wired to run from a single phase supply

Get a quote

ATO 30hp 22kW 220V Three Phase VFD, 3 Phase Input Output

ATO three phase input output VFD, 220V/ 240V/ 380V/ 480V 3 phase to 3 phase VFD variable frequency drive, sensorless vector variable frequency drive, RS485 enabled, strong overload

Get a quote

VFD Inverter 750W 1500W 2200W 220V in and 380V Out Single Phase 220V

About this item 1. Important note: This inverter is only suitable for three-phase 380V asynchronous motors 2. Input voltage: 220V (+/- 15%); Output voltage: 380VAC; Input

Get a quote

AC 220V/2.2kw 3HP Variable Frequency Drive,12A VFD Inverter

About this item 【BASIC PARAMETERS】This single phase vfd drive: 1 phase input and 3 phase output;Input voltage: 220V (+/-15%),Output voltage: 220V; Input frequency: 50/60 Hz,Output frequency: 0-400 Hz; The power is 2.2KW 3HP 12A, AC 220V; VFD Dimension: 4.61

Get a quote

How to connect a three-phase inverter to a 220v single-phase

The wiring method of converting a three-phase inverter to a 220V single-phase is a highly technical job, which requires a deep understanding of the working principle and wiring

Get a quote

Difference Between 220V & 380V 3-Phase Power

It is clarified that 220V is typically the phase-to-neutral voltage, while 380V is the phase-to-phase voltage in a three-phase system. Inverters

Get a quote

3-phase to inverter/charger

For a 2 or 3 circuit critical loads panel, what 48v (3-5k) inverter/chargers will accept two 127v hot lines and output 220v while powered and in inverter-only mode.

Get a quote

6 FAQs about [Can a three-phase inverter output 220v ]

What is the rated current of a 3 phase inverter?

Rated current 45A at 380V to 480V, 91A at 220V to 240V. The three-phase inverters with sensorless vector control are widely used in high-efficiency scenarios such as heavy machinery, motors, and equipment. 30 kW (40 hp) reliable frequency inverter, 3 phase 240V/420V/480V for choice. Rated current is 60A at 380V ~ 480V, and 112A at 220V ~ 240V.

How many conduction modes are there in a 3 phase inverter?

However in three-phase inverters , this voltage is distributed across three phases to create a balanced three-phase AC output . There are two primary conduction modes in both single-phase and three-phase inverters i.e.. 120-degree conduction mode and the 180-degree conduction mode.

Is a 3 phase inverter better?

The short answer: It depends. A 3 phase inverter is better and ideal for large solar installations. If you have a big solar panel array and high power demands, a 3-phase inverter is the way to go. It handles much more power and manages it efficiently. It is not ideal for small homes or businesses.

What is a 3 phase solar inverter?

Three phase solar inverters have an advantage over single phase inverters when installed in a solar system on a property with a 3 phase supply. Their advantage is that they splits the AC converted electricity from the solar panels into three batches each time. They are more efficient and can handle more power than single-phase solar inverters.

Can a 230V rotary phase converter be used as a 3 phase transformer?

Another option would be to use a 230V rotary phase converter and then step up from there with a 3 phase 460:230 VAC transformer wired backwards. One advantage of this is that most transformers have adjustable taps and this allows you to balance phases a little easier. And it seems these transformers are available as surplus for less cost.

How much torque does a 3 phase inverter have?

Start torque reaches 150% of rating torque at 1Hz. 3 phase inverter with output voltage 3 phase AC 0~input voltage can work at (–10℃, 40℃). Reliable 160 kW variable frequency inverter, 3 phase inverter input voltage 240V /420V /480V AC ±15% can be optional.

Guess what you want to know

-

Will the three-phase inverter output overlap

Will the three-phase inverter output overlap

-

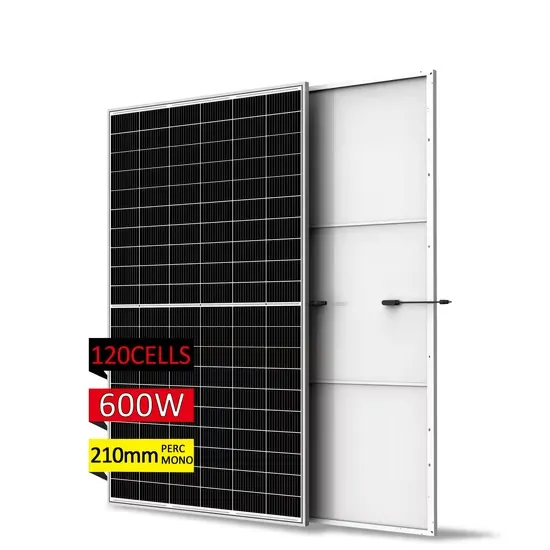

Photovoltaic and energy storage integrated inverter three-phase 220v

Photovoltaic and energy storage integrated inverter three-phase 220v

-

Three-phase inverter output

Three-phase inverter output

-

Inverter 220V output

Inverter 220V output

-

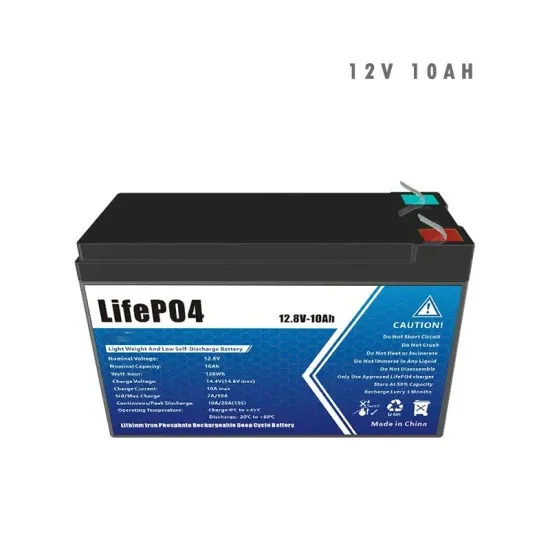

Lithium battery conversion 220v power inverter

Lithium battery conversion 220v power inverter

-

Can the inverter reach 220v

Can the inverter reach 220v

-

Inverter DC 36V output

Inverter DC 36V output

-

12v 46v inverter to 220v

12v 46v inverter to 220v

-

The simplest 3v to 220v inverter

The simplest 3v to 220v inverter

-

220v mechanical inverter

220v mechanical inverter

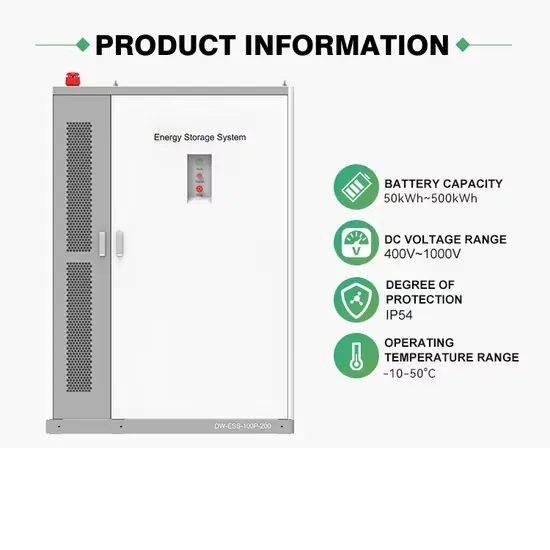

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.