Battery Manufacturing Capacity Market Data: Top Countries and

Discover top countries leading battery production, gigafactory expansions, and market data on global battery manufacturing.

Get a quote

Hyundai battery plant faces at least 2-3 month delay following

2 days ago· A battery plant co-owned by Hyundai Motor is facing a minimum delay of two to three months following an immigration raid last week, CEO Jose Munoz said.

Get a quote

What Are Battery Rack Cabinets and Why Are They Essential?

Battery rack cabinets are secure, organized, and often climate-controlled enclosures designed to safely store, protect, and charge multiple batteries, especially lithium

Get a quote

Unpacking claims Hyundai is closing Georgia plant following ICE

4 days ago· Claims that car manufacturer Hyundai would be closing down a sprawling auto plant "megasite" located in rural Georgia spread across the internet in early September 2025. The

Get a quote

Energy Storage Battery Production in 2025: What''s Powering the

With global renewable energy adoption skyrocketing, the battery industry is sprinting to keep up. Let''s unpack the trends, challenges, and innovations that''ll define this

Get a quote

EV Battery Manufacturing Could Boom In The U.S. This Year

According to a report from Inside Climate News, a whopping 10 new electric vehicle battery factories are expected to open in the U.S. this year. That includes plants from

Get a quote

Top Lithium-ion Battery Manufacturers in Spain 2025

Branches: Factory in Anhui (China), Thailand, branches in Germany and the US. Recent News: In 2025, Tritek partnered with TAKUNI and WTL to establish a lithium-ion battery factory in

Get a quote

China switches on its largest standalone battery storage project

The first phase of the Huadian Xinjiang Kashgar, China''s largest standalone battery energy storage project, was commissioned on July 19. The 500 MW/ 2 GWh plant represents

Get a quote

Eve Energy starts production of all-solid-state batteries for

The all-solid-state battery cell achieves an energy density of up to 300 Wh/kg or 700 Wh/L. Eve Energy is constructing a solid-state battery production base in Chengdu,

Get a quote

U.S. Battery Gigafactories [2025 List] | EV Supply Chain

This is a list of all lithium battery gigafactories in the U.S. and the major ones worldwide. A large gigafactory can consume 2.4 GWh of electricity and 1 million gallons of water daily.

Get a quote

EV Battery Manufacturing Could Boom In The U.S.

According to a report from Inside Climate News, a whopping 10 new electric vehicle battery factories are expected to open in the U.S. this

Get a quote

Case Study on ESTEL Outdoor Battery Cabinets in 2025

Discover how ESTEL outdoor battery cabinets ensure reliable energy storage in renewable projects, even in harsh environments, as shown

Get a quote

Exploring the World of Cabinet Type Energy Storage Battery

Looking ahead, research and development remain pivotal in shaping the future of cabinet type energy storage batteries. Innovations in battery chemistry, efficiency

Get a quote

U.S. Battery Gigafactories [2025 List] | EV Supply

This is a list of all lithium battery gigafactories in the U.S. and the major ones worldwide. A large gigafactory can consume 2.4 GWh of electricity and 1

Get a quote

Tracking the EV battery factory construction boom across North

Battery factories are popping up across North America. Here''s where they are and how the Inflation Reduction Act influenced the boom.

Get a quote

Case Study on ESTEL Outdoor Battery Cabinets in 2025

Discover how ESTEL outdoor battery cabinets ensure reliable energy storage in renewable projects, even in harsh environments, as shown in a 2025 case study.

Get a quote

2025 Battery Roadmaps

Perhaps closer to describe this as a start of 2025 review of the latest battery roadmaps, research and funding directions that will shape the industry. Here we look at the

Get a quote

CATL Battery Factory • CÉH

CATL Battery Factory The investment is the largest European battery plant to date by Chinese company CATL, being built in Debrecen, in the Southern

Get a quote

China Ups Battery Cabinet, Ups Battery Cabinet Wholesale,

China Ups Battery Cabinet wholesale - Select 2025 high quality Ups Battery Cabinet products in best price from certified Chinese UPS Battery manufacturers, Storage Battery suppliers,

Get a quote

A stunning number of electric vehicle, battery factories

According to data from Atlas Public Policy, a policy research group, more projects were canceled in the first quarter of 2025 than in the previous

Get a quote

ICE operation pauses construction at Hyundai megasite in

ELLABELL, Ga. (WTOC) - Federal and state law enforcement carried out a major operation Thursday at the HL-GA Battery construction site on the Hyundai megasite in Bryan

Get a quote

Top 10 Global Leaders Powering Battery Innovation Revolution

These 10 battery innovation leaders are transforming EVs, energy storage, and recycling through futuristic technologies and breakthroughs.

Get a quote

Tracking the EV battery factory construction boom

Battery factories are popping up across North America. Here''s where they are and how the Inflation Reduction Act influenced the boom.

Get a quote

Tesla unveils its LFP battery factory, claims it''s almost

Tesla has unveiled its lithium-iron-phosphate (LFP) battery cell factory in Nevada and claims that it is nearly ready to start production. Like

Get a quote

Top 10 Lithium-Ion Battery Manufacturers In The World

This article will discuss the top 10 lithium-ion battery manufacturers that play a major role in advancing lithium-ion products; CATL, LG, Panasonic,

Get a quote

A stunning number of electric vehicle, battery factories are being

According to data from Atlas Public Policy, a policy research group, more projects were canceled in the first quarter of 2025 than in the previous two years combined.

Get a quote

6 FAQs about [Battery Cabinet Factory in 2025]

What is the battery cell factory of the future?

The battery cell factory of the future addresses the challenges of cost optimization through improvements in four dimensions. (See Exhibit 3.) Each dimension encompasses a variety of innovative measures, spanning different levels of technological maturity. (See “Technology Maturity Levels.”) Research Phase.

Will the factory of the future reduce conversion costs in battery cell production?

We estimate that the factory of the future will reduce conversion costs in battery cell production by 20% to 30% from the 2024 baseline. (See Exhibit 5.) Cost savings can be achieved across the entire production process, with the most significant impacts on electrode production.

How do battery cell producers prepare for the factory of the future?

To navigate these challenges and capitalize on the benefits of the factory of the future, battery cell producers should take the following steps: Evaluate optimization levers. Assess the business maturity and financial implications of optimization measures across each dimension of the factory of the future. Assess fit.

How can battery cell producers improve cost efficiency?

By adopting this approach, battery cell producers can improve cost efficiency by up to 30% compared with the current industry average. As price pressure builds amid overcapacity, this is a pivotal moment for decision makers to define their vision for the factory of the future.

How much electricity does a battery factory use?

A large gigafactory can consume 2.4 GWh of electricity and 1 million gallons of water daily. Battery factories assemble the individual battery cells into a functioning battery pack with a battery management system (BMS) and thermal management system (TMS) and enclosure.

Are battery chemistries and form factors the future?

The future dominance of specific battery chemistries and form factors is uncertain, adding complexity to investment decisions. Transitioning to new chemistries or cell formats can be expensive.

Guess what you want to know

-

2025 Battery Cabinet Major Brands

2025 Battery Cabinet Major Brands

-

Peru Energy Storage Lithium Battery Station Cabinet Factory

Peru Energy Storage Lithium Battery Station Cabinet Factory

-

How big is the energy storage cabinet battery headquarters factory

How big is the energy storage cabinet battery headquarters factory

-

Factory lithium battery station cabinet

Factory lithium battery station cabinet

-

Factory direct sales energy storage cabinet battery price

Factory direct sales energy storage cabinet battery price

-

Spanish outdoor communication battery cabinet wholesale factory direct sales

Spanish outdoor communication battery cabinet wholesale factory direct sales

-

Slovenia lithium battery station cabinet factory

Slovenia lithium battery station cabinet factory

-

Albania lithium battery energy storage cabinet installation factory is running

Albania lithium battery energy storage cabinet installation factory is running

-

Hungary photovoltaic energy storage cabinet battery factory base station

Hungary photovoltaic energy storage cabinet battery factory base station

-

Battery Cabinet in 2025

Battery Cabinet in 2025

Industrial & Commercial Energy Storage Market Growth

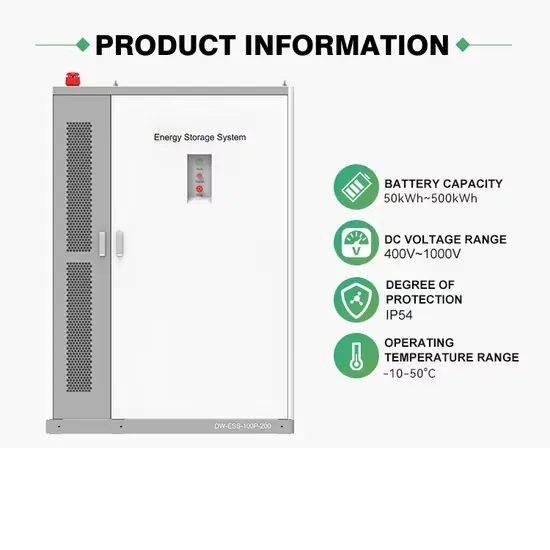

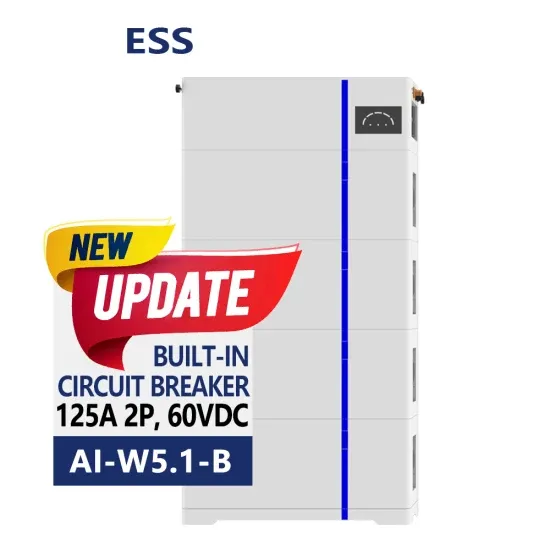

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.